Uncover the Different Types of Bridge Expansion Joints for Enhanced Infrastructure

By:Admin

Introduction:

As our society continues to evolve, the need to improve our infrastructure becomes even more crucial. One vital component of infrastructure development is the construction and maintenance of bridges. These structures must be designed to endure heavy traffic, harsh weather conditions, and ensure the safety of the traveling public. In this article, we will explore various types of bridge expansion joints that play a vital role in increasing bridge durability and reducing maintenance costs.

1. Modular Joints:

Modular joints are a widely used type of expansion joint in modern bridge construction. These joints consist of a series of steel-edge beams connected by elastomeric seals. By allowing controlled movement during thermal expansion and contraction, modular joints enhance the bridge's ability to withstand temperature variations. They also provide a smooth ride for vehicles, eliminate noise and vibrations, and reduce stress on the bridge deck.

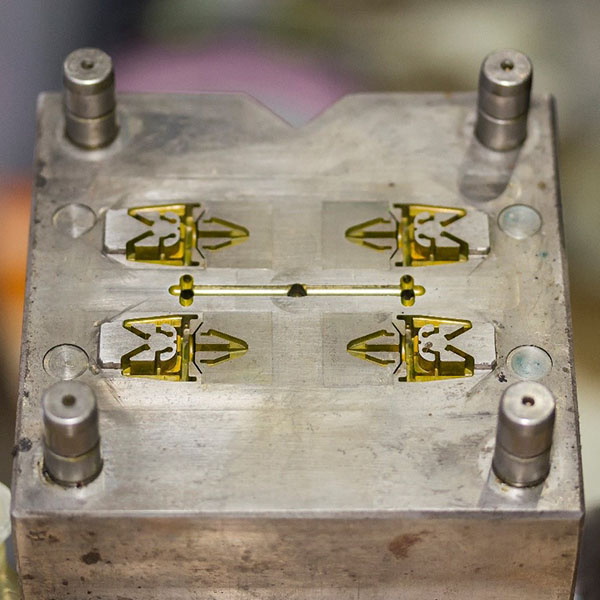

2. Finger Joints:

Finger joints, also known as comb joints, are another popular type of expansion joint commonly found in bridge construction. These joints offer significant movement capability and are designed to accommodate horizontal and vertical displacements. Finger joints consist of multiple steel plates with interlocking fingers, enabling the bridge to flex while maintaining structural integrity. While versatile and cost-effective, finger joints require regular maintenance to prevent debris accumulation and ensuring optimal functionality.

3. Sliding Plate Joints:

Sliding plate joints, as the name suggests, incorporate sliding elements to facilitate bridge displacement while maintaining stability. These joints consist of two plates that glide over one another to accommodate expansion and contraction of bridge components. The sliding plate joints effectively alleviate stress on the bridge structure, reducing internal forces and minimizing the risk of damage caused by temperature fluctuation. Regular lubrication is essential to ensure the smooth functioning of sliding plate joints.

4. Elastomeric Joints:

Elastomeric joints are flexible and provide exceptional movement accommodation, making them suitable for use in both highway and railway bridges. These joints are constructed using flexible rubber-like materials combined with steel reinforcements. Elastomeric joints isolate vibrations and transmit vertical and horizontal movements between bridge sections, reducing the potential for structural damage and enhancing passenger comfort. Routine inspections and maintenance are vital to monitor the condition of the elastomeric material and ensure optimal performance.

5. Selective Movement Joints:

Selective movement joints are specialized for accommodating the differential movement between adjacent bridge sections. This type of expansion joint allows for various types of movement, including lateral and rotational motions. Selective movement joints often feature a combination of materials, such as rubber and metal, to achieve the required functionality. Regular inspections and maintenance are necessary to preserve the desired range of motion and prevent potential joint failure.

Conclusion:

Bridge expansion joints are a vital part of infrastructure design, allowing for flexibility and durability in the face of dynamic environmental conditions. By understanding the various types of expansion joints available, engineers can ensure long-lasting bridge structures that offer enhanced resilience, reduced maintenance costs, and improved user experience. Investing in proper maintenance and periodic inspections will help maintain the effectiveness of these joints and contribute to the longevity and safety of our vital transportation infrastructure.

Company News & Blog

What is a Back Pressure Regulating Valve? (BPRV)

In many industrial applications, controlling fluid flow and pressure is of utmost importance. One of the critical components used for this purpose is the Back Pressure Regulating Valve (BPRV). BPRV is a valve that ensures that a minimum safe pressure is maintained in a fluid system's upstream section, regardless of changes in flow or downstream pressure. It is commonly used in chemical, pharmaceutical, and oil and gas industries, among others.BPRVs work by controlling the pressure of a fluid flowing from a system in the downstream direction, back to the upstream side. It is designed in such a way that it can relieve or maintain pressure in the system by regulating flow. It helps in preventing any damage to the equipment and ensures stable and efficient operations. The BPRV comes in various shapes, sizes, and materials, depending on the industry and its application.One of the essential features of the Back Pressure Regulating Valve is its ability to regulate pressure in both liquid and gaseous systems. The design of the valve is such that it can handle both low and high-pressure applications, making it versatile in its use. Furthermore, it helps protect the system against pressure variations, which can lead to safety issues or even equipment damage.The applications of BPRVs in various industries are many. In the chemical industry, where chemical reactions are susceptible to pressure changes, the BPRV regulates the pressure and helps maintain safe and consistent reactions. In pharmaceutical industries, where sterile conditions are critical, BPRVs maintain the pressure conditions to prevent contamination. In the oil and gas industry, where changes in temperature and pressure are common, BPRVs regulate the flow and pressure levels, ensuring smooth operations.The Back Pressure Regulating Valve's importance in any fluid system cannot be overstated. It provides a reliable and efficient solution to control the pressure and flow of liquids and gasses, thereby preventing system failure, equipment damage, and safety hazards. Additionally, when integrated with other control devices, the BPRV can enhance the performance of the overall fluid system, leading to increased productivity, energy savings, and reduced costs.In conclusion, the Back Pressure Regulating Valve is an essential component in many industries, providing safe, effective, and reliable pressure regulation and flow control. Its versatility, durability, and efficiency make it a must-have for any fluid system. As industries continue to evolve, the BPRV will undoubtedly play a significant role in ensuring safe and efficient operations.

Durable Slurry Hoses for Handling Abrasive Materials

Slurry hose and mud hose are crucial components in the operations of mines and quarries. They play a vital role in transporting abrasive and viscous slurries, which are byproducts of mining and quarrying activities. Without these hoses, the transportation of these materials would be challenging and costly.Recognizing the importance of slurry hoses and mud hoses, China's rubber industry has been actively manufacturing and supplying these vital components to various industries across the globe. China is a recognized hub for rubber production, and its manufacturers are renowned for their exceptional engineering expertise, high-quality materials, and user-friendly designs.One such manufacturer is [insert brand name], a leading supplier and manufacturer of slurry hoses and mud hoses. The company has been manufacturing and supplying these hoses for over a decade, providing exceptional service to its clients across the globe. By integrating the latest technology and consistently improving their manufacturing processes, they have been able to produce superior quality hoses at competitive prices.Slurry hoses are primarily designed to handle abrasive and viscous slurries. The hoses are made of high-quality blended rubber, which can withstand the abrasive nature of the materials, reducing the risk of wear and tear. The external bolt-on flanges design of the hoses allows for easy installation, uninterrupted free flow and makes maintenance much easier.Mud hoses, on the other hand, are designed to handle heavy mud and sludge materials. The hoses are made of premium quality materials that can withstand the heavy pressure of the materials transported. The smooth interior of the hose facilitates the smooth flow of materials, preventing blockages and ensuring a consistent flow.[Insert brand name] has gone beyond producing standard slurry hoses and mud hoses. The manufacturer also produces customized hoses to meet the specific needs of clients. Their team of experts utilizes the latest engineering software to design and produce hoses that are specific to individual requirements. Whether it is with regards to shape, length, or diameter, [insert brand name] always delivers quality hoses that meet the demands of the client.Quality is essential to the team at [insert brand name]. The company's professional team of engineers and technicians ensures that the manufacturing process follows strict guidelines and is compliant with international standards such as ISO and API. They use high-quality raw materials to ensure that the end product is durable, reliable, and safe.In addition to the superior quality of their products, [insert brand name] also prides itself on its exceptional customer service. The team is dedicated to providing excellent service to clients, ensuring that all their requirements are met promptly and efficiently. They have an excellent after-sales service, which ensures that clients receive the necessary support and assistance they require throughout the life of the product.The company also offers competitive pricing for their products without compromising on the quality. Their pricing strategy is aimed at providing affordable solutions to their clients without sacrificing the quality of their products. This strategy has played a considerable role in making [insert brand name] a preferred choice for clients across the globe.In conclusion, slurry hose and mud hose are essential components of the mining and quarrying industry. The quality of the hoses used can affect the productivity, cost, and safety of the operations. Investing in high-quality hoses from a reputable supplier such as [insert brand name] is crucial for any mining or quarrying operation. With their exceptional products, competitive pricing, and excellent customer service, [insert brand name] is a manufacturing industry leader that has become a trusted partner to clients worldwide.

Find Hot Rolled Steel Pipes in Various Sizes at Metal Supermarkets" - SEO title without brand name.

Title: A Comprehensive Guide to Hot Rolled Steel Pipes for Diverse ApplicationsIntroduction:Hot rolled steel pipes have become a cornerstone in various industries, thanks to their exceptional strength and versatility. In this blog post, we will explore the crucial aspects of hot rolled steel pipes, their applications, and the benefits they offer. Whether you are seeking information as a consumer or an industry professional, this guide will help you understand hot rolled steel pipes better.Understanding Hot Rolled Steel Pipes:Hot rolled steel pipes are produced through a process that involves heating a steel billet above its recrystallization temperature and then passing it through rollers at high temperatures. This process enhances the mechanical properties of the pipe, making it extremely durable and suitable for various applications. Hot rolled steel pipes are generally characterized by a dark-colored oxide scale on their outer surface, adding to their distinctive appearance.Key Advantages of Hot Rolled Steel Pipes:1. Strength and Durability: Hot rolled steel pipes are known for their exceptional strength, making them ideal for applications requiring high load-bearing capacity. Their durability further ensures longevity, making them a cost-effective choice for both residential and industrial projects.2. Versatility: Hot rolled steel pipes come in a wide range of sizes to meet diverse application needs. From small-scale projects to large-scale industrial applications, these pipes offer versatile solutions that adapt to various project requirements.3. Structural Integrity: The production process of hot rolled steel pipes helps preserve and enhance the material's structural integrity. The extensive heating and rolling eliminate internal stresses and ensure uniformity, enabling the pipes to withstand demanding conditions.Applications of Hot Rolled Steel Pipes:1. Construction Industry: Hot rolled steel pipes find extensive use in the construction sector due to their incredible strength and durability. These pipes are commonly employed in structural projects such as building frames, infrastructure development, and bridges.2. Oil and Gas Industry: The oil and gas sector greatly benefit from hot rolled steel pipes due to their exceptional resistance to corrosion and high-temperature environments. These pipes are widely used for oil and gas transmission, drilling, and as casing pipes for well completion.3. Automotive Industry: Hot rolled steel pipes are extensively used in the automotive industry for their superior strength and rigidity. Their applications range from exhaust systems and chassis components to automotive frames, where structural integrity is of utmost importance.4. Manufacturing and Industrial Applications: With their excellent durability and versatility, hot rolled steel pipes serve several applications in manufacturing and industrial settings. These include conveyor systems, hydraulic systems, boilers, and heat exchangers, among others.5. Infrastructure and Utilities: Hot rolled steel pipes play a crucial role in water and sewage treatment facilities, as well as in the transportation of water, gas, and other fluids. Their corrosion resistance and durability make them an ideal choice for long-term use in such critical applications.Conclusion:Hot rolled steel pipes offer an array of benefits, from exceptional strength and durability to versatility in diverse applications. Their widespread use in various industries demonstrates their reliability and high-performance capabilities. If you require hot rolled steel pipes for your next project, consult with trusted suppliers who prioritize quality and offer a wide range of sizes to meet your specific needs.

Discover the Benefits of PVC Rubber for Custom Military Patches with Velcro Backing

Custom Military Patches: Why PVC Rubber Is Your Best Choice?Custom military patches are a great way to show affiliation, commemorate service, and recognize bravery. Whether you’re in the military, a veteran, or a civilian supporter, a high-quality patch can make a big difference. But when it comes to choosing the right material for your custom military patches, not all options are created equal.Enter PVC rubber, the material of choice for many military and law enforcement agencies around the world. In this article, we’ll explore why PVC rubber is the best choice for custom military patches, and why you should consider it for your next custom patch project.What is PVC Rubber?First, let’s define what PVC rubber actually is. PVC (polyvinyl chloride) is a synthetic plastic polymer that is widely used in a variety of industries, from construction to healthcare to fashion. In the case of custom patches, PVC rubber is created by injecting liquid PVC into custom molds, then allowing them to cool and solidify into a soft, flexible rubber material.PVC rubber is known for its durability, flexibility, and 3D texture. It can be molded into a variety of shapes, sizes, and colors, making it an ideal material for custom patches, labels, and keychains. And, unlike other materials that can fray, fade, or crack over time, PVC rubber is built to last, even in harsh environments.Why PVC Rubber is the Best Choice for Custom Military PatchesNow that we know what PVC rubber is, let's dive into why it's the best choice for custom military patches.1. DurableFirst and foremost, PVC rubber is incredibly durable. It’s resistant to water, chemicals, abrasions, and extreme temperatures, making it an ideal material for military patches that need to withstand harsh environments. Whether you're on the battlefield, in the line of duty, or simply need a patch that will last for years, PVC rubber delivers.2. 3D TexturePVC rubber allows for a 3D texture and a raised design, making your patch stand out in a crowded field of flat, low-quality patches. This is especially important for military patches, which often have detailed designs, text, and symbols that need to be clearly visible at all times.3. CustomizablePVC rubber can be easily molded into any shape, size, or color, making it ideal for custom patches. Whether you need a patch that matches your unit's colors, or a patch that includes your specific rank, PVC rubber can deliver. And, because it's a synthetic material, it can be colored to match any shade or hue.4. Velcro BackingMany military and law enforcement agencies prefer Velcro backing on their patches, as it allows for easy attachment and removal from tactical uniforms and gear. PVC rubber can be easily molded with Velcro backing, making it a seamless choice for these types of applications.5. Cost EffectiveFinally, PVC rubber is a cost-effective choice for custom military patches. While other materials may be more expensive, PVC rubber delivers a high-quality look and feel at an affordable price point. This makes it an ideal material for unit patches, morale patches, and other custom patches that need to be distributed in large quantities.Customized Rubber Accessories: Your Source for High-Quality PVC Military PatchesIf you’re looking for a reliable partner for your custom military patch project, look no further than Customized Rubber Accessories. At CRA, we specialize in creating high-quality PVC rubber patches, labels, and keychains for military and law enforcement agencies around the world.Our team of expert designers and craftsmen can help you create a custom patch that truly stands out, with detailed 3D designs, custom shapes and sizes, and Velcro backing for easy attachment. And, with quick turnaround times, affordable prices, and a commitment to quality, we’re the ideal choice for any custom patch project, large or small.In ConclusionPVC rubber is the clear choice for custom military patches, thanks to its durability, 3D texture, customizability, Velcro backing, and cost effectiveness. And with Customized Rubber Accessories as your partner, you can rest assured that your custom patches will be of the highest quality, designed to last for years of service and beyond. Contact us today to learn more about our services and get started on your custom military patch project!

Discover the Functional and Stylish Fire Screen Mesh for Ultimate Protection

Fire Screen Mesh: The Ultimate Protection Against Fire HazardsIn an effort to prioritize safety, Fire Screen Mesh (brand name omitted) has emerged as the market leader in providing innovative fire protection solutions. With a steadfast commitment to quality and unrivaled technology, the company aims to safeguard homes and businesses from the dire consequences of fire accidents. Their dedication to excellence, combined with a comprehensive range of products, demonstrates their belief that prevention is the key to minimizing fire hazards.Fire accidents have always posed a significant threat, causing extensive damage to properties and putting lives at risk. According to the National Fire Protection Association (NFPA), in the United States alone, an estimated 355,400 residential fires were reported in 2019, resulting in 2,620 deaths and a staggering $7.8 billion in property damage. It is clear that a proactive approach to fire prevention is essential, and Fire Screen Mesh is paving the way with their cutting-edge technology.With a focus on research and development, Fire Screen Mesh has revolutionized fire protection. Their range of fire-resistant screens offers homeowners and businesses an effective barrier against flames and embers, creating a safe environment and allowing occupants valuable time to evacuate in case of an emergency. The secret lies in the advanced materials used in the manufacturing process, which undergo stringent testing to adhere to international safety standards.The company's fire-resistant screens are designed to be seamlessly integrated into windows, doors, and vents, providing maximum protection without compromising aesthetics. This innovative approach ensures that Fire Screen Mesh caters to both functional and visual requirements, making their products suitable for a wide array of architectural styles. Moreover, the screens are easy to maintain and are available in various sizes and colors to suit individual preferences.In addition to residential applications, Fire Screen Mesh caters to the commercial sector as well. Their expertise extends to large-scale projects such as high-rise buildings, hospitals, and educational institutions. By installing fire-resistant screens in critical areas, businesses can mitigate the risks associated with fire hazards, safeguarding their employees, customers, and valuable assets.Fire Screen Mesh prides itself on customer satisfaction and goes the extra mile in providing top-notch service. Their team of highly qualified professionals offers personalized consultations, ensuring that clients find the ideal fire protection solution based on their specific needs. From design to installation, the company's dedicated experts guide clients through every step of the process, guaranteeing hassle-free implementation and peace of mind.Additionally, Fire Screen Mesh understands the importance of staying up to date with ever-changing safety regulations. By continuously investing in research and development, the company remains at the forefront of technological advancements in fire protection. This commitment allows them to adapt their products to meet evolving industry standards, giving clients the assurance that Fire Screen Mesh consistently delivers the most effective and reliable fire-resistant screens on the market.As an environmentally conscious company, Fire Screen Mesh prioritizes sustainability. Their products are made using eco-friendly materials, ensuring minimal impact on the environment while providing superior fire protection. By reducing the use of harmful chemicals, the company reinforces its dedication to protecting not only lives and property but also the planet we call home.In conclusion, Fire Screen Mesh (brand name omitted) stands as an industry leader in fire protection solutions. Their commitment to excellence, advanced technology, and personalized service make them the go-to choice for homeowners and businesses alike. By focusing on prevention and offering innovative fire-resistant screens, the company aims to minimize fire hazards and promote a safer environment for all. With Fire Screen Mesh, the future of fire protection looks brighter than ever.

Resilient Seated Gate Valves Show Resilience in Challenging Applications

Resilient Seated Gate Valves - An Exceptional and Reliable Solution for Industrial NeedsResilient Seated Gate Valves have become an integral component of industrial processes and manufacturing procedures across various sectors. They are compact, lightweight, and highly durable, making them a reliable choice for countless applications. {The Company} manufactures and supplies a wide range of high-quality resilient seated gate valves that meet the industry standards and cater to different applications. These valves play a critical role in ensuring the seamless flow of liquids and gases across pipelines, processing plants, and manufacturing facilities.But what are Resilient Seated Gate Valves?Resilient Seated Gate Valves, shortly known as RSGV, are a type of isolation valve commonly used to regulate the flow of fluids or gases. The valve consists of a flat, rectangular closure element that slides up and down to allow or stop the flow of liquids or gases. The closure element is held by a set of guides and a stem, which, when rotated, raises or lowers the gate. The valve features an elastomeric (rubber) seat that ensures leak-tight sealing, even in low-pressure applications.The Benefits of Resilient Seated Gate ValvesResilient Seated Gate Valves offer many benefits compared to other types of valves. Here's a brief overview:1. Low Maintenance: Since they have a simple and compact design, these valves require minimal maintenance, saving time and effort.2. Longevity: Resilient Seated Gate Valves are built to last, withstanding harsh temperature and pressure conditions.3. Corrosion-Resistant: RSGVs are made of materials that are highly resistant to corrosion and abrasion, ensuring their longevity and reliability.4. Versatile: Resilient Seated Gate valves can be used in several applications, including water treatment, oil and gas, food, and beverage processing, among others.5. Cost-Effective: These valves are cost-effective and offer excellent value for money, making them a popular choice amongst manufacturers and engineers.The Applications of Resilient Seated Gate ValvesResilient Seated Gate Valves find a wide range of applications across various industries. They are often used in:1. Water Treatment: These valves are extensively used in water treatment plants to regulate the flow of water.2. Oil and Gas: RSGVs are used to control the flow of oil and gas in pipelines, refineries, and processing plants.3. Food and Beverage: These valves are a popular choice for use in food and beverage processing plants, thanks to their hygienic design and leak-tight sealing.4. Pharmaceutical: RSGVs are also used in the pharmaceutical industry to regulate the flow of fluids and gases.{The Company} - Delivering High-Quality Resilient Seated Gate Valves{The Company} is a leading manufacturer of resilient seated gate valves in the industry with over a decade of experience. They specialize in the production and supply of high-quality valves that are guaranteed to offer exceptional performance, durability, and efficiency. The company upholds stringent quality standards and produces valves that comply with the industry standards, including ISO, CE, and API.{The Company} offers an extensive range of RSGV products that can cater to different applications and customer requirements. The valves are available in various sizes ranging from 50mm to 2000mm and have a working pressure between 10 bars to 25 bars. Additionally, the valves come equipped with several features, including EPDM or NBR vulcanized rubber lining, ductile iron body, and stainless steel stem.The company also has a team of experienced engineers and technicians who work diligently to develop customized solutions tailor-made to specific customer needs. They are committed to delivering the highest quality products and services to their customers, making them a trusted partner for the industrial market.In conclusion, Resilient Seated Gate Valves have become an essential component of industrial processes, specifically those that require control of fluid and gas flow. Their versatility, durability, and efficiency make them an excellent choice for various applications in different industries. For individuals and businesses looking to purchase high-quality resilient seated gate valves, {The Company} is the trusted vendor for you.

Mechanical Devices for Material Movement: A Guide to Conveyors

Live Roller Conveyors: Streamlining Industrial Material HandlingEfficient material handling is crucial for any industrial operation. That is why sophisticated conveyors play a significant role in large farms, warehousing, freight handling, and industrial applications. One such type of conveyor is the Live Roller Conveyor.Live Roller Conveyor is an automated conveyor system that provides mechanized movement of materials by using rollers mounted on a conveyor bed. These rollers transport goods by rotating, which in turn, moves the products along the conveyor bed.Benefits of Live Roller Conveyors1. Continuous MovementLive Roller Conveyor is a high-speed system that can transport materials continuously. This allows for an uninterrupted flow of goods, ensuring the efficient movement of materials from one location to another.2. High Load CapacityLive Roller Conveyors can handle high loads, making them ideal for heavy-duty applications in industries such as automotive, manufacturing, and distribution.3. VersatilityLive Roller Conveyors are ideal for conveying a wide variety of materials, including boxes, packages, totes, and pallets. They can accommodate irregularly shaped items and can be customized with various roller widths, lengths, and configurations to suit specific material handling needs.4. Increased EfficiencyBy automating the material handling process, Live Roller Conveyors reduce manual labor requirements, minimizing errors, and saving valuable time. This translates to increased productivity and cost savings.5. Minimal MaintenanceLive Roller Conveyors have a simple design, making them easy to maintain, and require minimal upkeep. Their robust construction ensures durability and longevity even in the harshest industrial environments.6. SafetyLive Roller Conveyors comply with strict safety standards, making them a safe and reliable material handling solution. They are designed with features such as emergency stop buttons, safety guarding, and automatic shutoffs to prevent accidents.Applications of Live Roller ConveyorsLive Roller Conveyors are used in several industrial applications, including:1. Distribution CentersLive Roller Conveyors are ideal for the efficient movement of goods in distribution centers, including sorting, accumulating, merging, and diverting packages and parcels.2. ManufacturingLive Roller Conveyors transport raw materials and finished products on the factory floor, including heavy-duty assemblies, automotive components, and steel parts.3. WarehousingLive Roller Conveyors move products in and out of warehouses, minimizing manual labor and increasing efficiency.4. Food IndustryLive Roller Conveyors transport food and beverage products, including canned goods, bottles, and packaged food items, in a hygienic, safe, and efficient manner.In conclusion, Live Roller Conveyors are a smart investment for any industrial operation that emphasizes efficiency, safety, and cost savings. They streamline material handling, increase productivity, and reduce manual labor requirements. Whoever looking for high-performance material handling solutions should consider the benefits of a Live Roller Conveyor.

Pipe Lining and Coating: Why Polyurethane Lined Steel Pipe is the Way to GoPipe lining and coating have become increasingly important in the realm of infrastructure repair and maintenance. With aging pipelines and increased demand for water and waste water treatment, it is crucial to protect and revamp these systems to prevent environmental damage, contamination, and loss of valuable resources.At Vulcan Painters, we specialize in coating ductile iron pipe, steel pipe, and structural steel, as well as tanks and water and waste water equipment at sewage treatment facilities. Our expertise in pipe lining and coating has allowed us to become a trusted name in the industry, providing high-quality services that ensure the longevity and safety of pipelines.One type of pipe lining that we highly recommend for steel pipelines is polyurethane lining. Here are a few reasons why:1. Durable and Long-LastingPolyurethane lining is an incredibly durable material that can withstand extreme temperatures, chemicals, and abrasion. It is a highly resilient material that can last for many years, providing a low-maintenance solution to pipe repair and maintenance.2. Resistant to Corrosion and RustSteel pipes are often susceptible to corrosion and rust, which can lead to pipe failure and contamination. Polyurethane lining provides an impermeable barrier between the steel pipe and the environment, preventing rust and corrosion from occurring.3. Non-Toxic and SafePolyurethane lining is a non-toxic material that is safe for use with drinking water and other applications where food and beverages are involved. It is also an environmentally friendly solution that can reduce the need for pipe replacement, ultimately reducing waste and saving resources.4. Easy InstallationPolyurethane lining can be easily applied to steel pipes through a variety of methods, including spray-on, dipping, or rolling. This makes it a quick and cost-effective solution for pipeline repair and maintenance.Overall, polyurethane lined steel pipe offers a range of benefits that make it a superior choice for pipeline maintenance and repair. At Vulcan Painters, our expertise in pipe lining and coating, combined with our commitment to quality and service, ensure that our clients receive the best possible solutions for their pipeline needs.Keywords: Pipe Lining, Pipe Coating, Polyurethane Lining, Steel Pipe, Ductile Iron Pipe, Infrastructure Repair, Maintenance, Rust, Corrosion, Non-Toxic, Safe, Environmentally Friendly, Easy Installation, Vulcan Painters.

Discover the Benefits of Expansion Joint Rubber Gaskets for Optimal Performance

Rubber gaskets are an essential component in various industrial applications that require sealing between two surfaces to prevent any leakage. One of the most significant challenges faced by industries is the expansion and contraction of pipes due to extreme temperatures. The solution to this problem is the use of expansion joint rubber gaskets, which allows for movement and flexibility while maintaining a tight seal.One of the leading manufacturers of expansion joint rubber gaskets is a company that has been in the industry for over two decades. They specialize in providing high-quality industrial rubber products to their clients across various sectors, including oil and gas, water treatment, and food processing.Their expansion joint rubber gaskets are made of high-grade materials, which offer maximum durability, flexibility, and resistance to extreme temperatures and pressure. The gaskets are designed to allow for axial, lateral, and angular movement, making them ideal for use in piping systems that undergo frequent expansion and contraction.What makes their expansion joint rubber gaskets unique is their ability to withstand harsh environmental conditions. The gaskets can resist corrosion and chemical attacks, making them suitable for use in aggressive environments where conventional gaskets may fail to offer adequate protection.The company's expansion joint rubber gaskets are available in various widths, lengths, and thicknesses to provide an exact fit for different applications. They offer customized solutions to their clients, ensuring that the gaskets meet their specific requirements.The company's commitment to ensuring customer satisfaction is demonstrated by their stringent quality control measures. They have a team of experienced technicians who conduct rigorous tests on all their products before they leave the factory to ensure that they meet the required standards.In addition to their expansion joint rubber gaskets, the company also offers a wide range of industrial rubber products such as seals, gaskets, hoses, and O-rings. Their products are widely used in different industries due to their reliability, durability, and performance.The company's success is rooted in their dedication to providing top-quality products and exceptional customer service. They have a team of experts who provide technical support to their clients, ensuring that they have the right product for their specific needs.Their expansion joint rubber gaskets have been widely recognized for their performance and quality by different industry bodies. They have received several certifications, including the ISO 9001:2015 quality management system certification, which demonstrates their commitment to providing high-quality products.In conclusion, the use of expansion joint rubber gaskets is crucial in various industrial applications that require sealing between two surfaces. The company has established itself as a leading manufacturer of high-quality rubber products, including expansion joint rubber gaskets. Their products are reliable, durable, and offer maximum protection in harsh environmental conditions. With their commitment to quality and customer satisfaction, the company is well-positioned to continue providing innovative solutions to their clients across different sectors.