- Home

- Types Of Expansion Joints

Explore Different Types Of Expansion Joints - Your Trusted OEM Supplier in China

Arex Industrial Technology Co., Ltd. is a leading manufacturer, supplier, and factory of various types of expansion joints in China. Our expansion joints have been designed and manufactured to provide effective protection to the piping system against temperature changes, vibrations, and thermal deformations.

Our range of expansion joints includes single and double bellows, universal, hinged, gimbal, pressure balanced, and tied expansion joints. These expansion joints are made from high-quality materials such as stainless steel, carbon steel, and special alloys to provide maximum durability and performance.

Our single bellows expansion joints are suitable for absorbing axial and lateral movements, while double bellows expansion joints are designed to handle higher movement requirements. Universal expansion joints can absorb axial, lateral, and angular movements, while the hinged and gimbal expansion joints are designed for large angular movement applications.

Pressure balanced expansion joints are ideal for high-pressure applications, while tied expansion joints provide superior lateral stability. Arex Industrial Technology Co., Ltd. offers a range of expansion joints suitable for various applications for our clients in China and beyond.

Arex Industrial Technology Co.,Ltd.

Company News

Related News

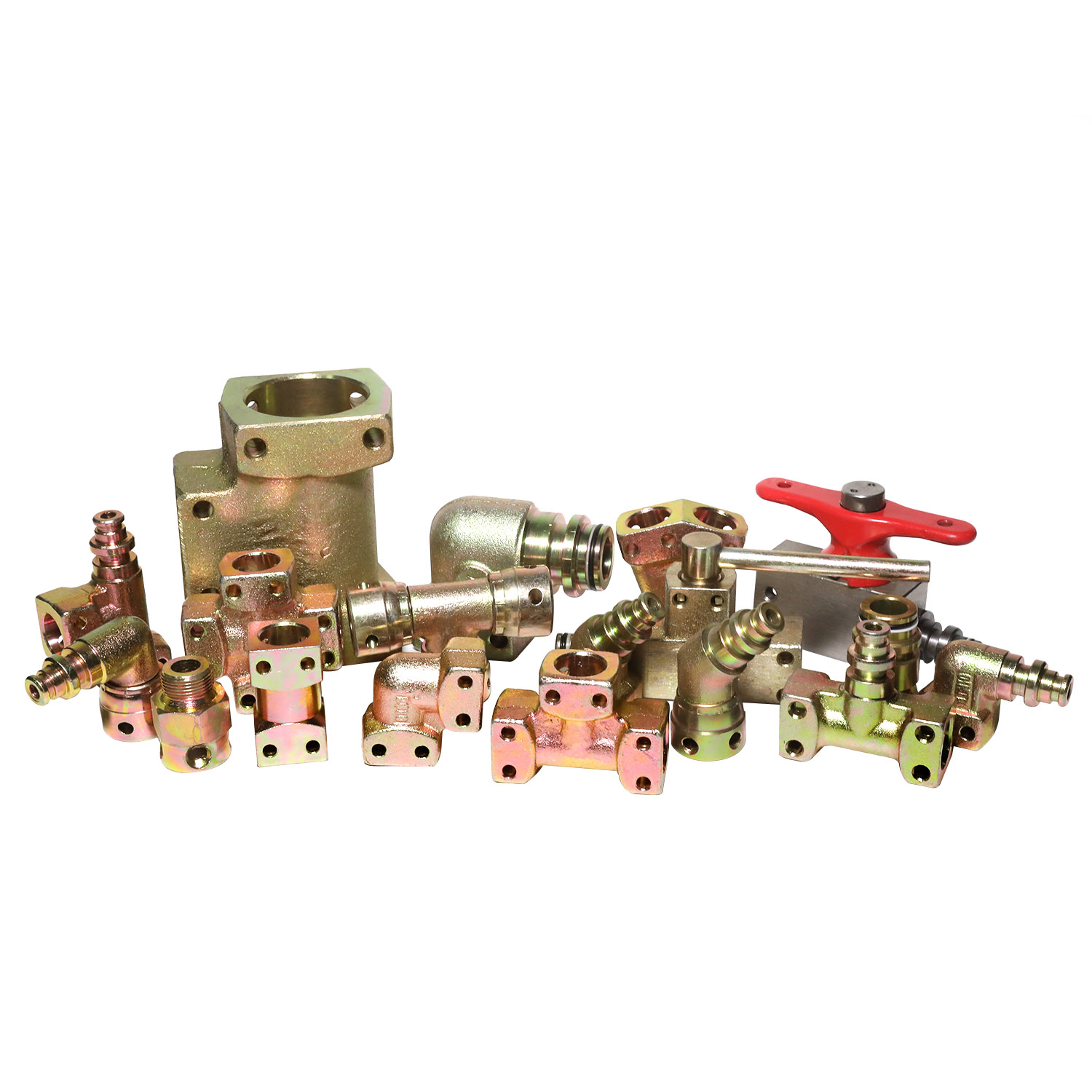

Hydraulic fittings

Looking for reliable hydraulic fittings? Look no further! Our factory produces high-quality fittings that ensure long-lasting performance. Order now. #hydraulics #factory #fittings

Hydraulic Staple-Lock Adaptors

As a factory, we specialize in producing top-quality hydraulic staple-lock adaptors for various applications. Our adaptors are durable, reliable, and easily connect to hydraulic systems. Discover our range today!

Ceramic Lined Rubber Hose

Looking for a high-quality Ceramic Lined Rubber Hose? Look no further than our factory! With years of experience, we are experts in producing superior products that last.

Polyurethane Stator And Rotor Of Flotation Machine

Our factory specializes in producing high-quality Polyurethane Stator and Rotor for Flotation Machines. Trust us for excellent performance and durability. Order now!

Rubber Expansion Joints

Looking for high-quality rubber expansion joints? Look no further than our factory! Our expertly crafted products provide excellent durability and performance to meet your needs. Shop now! #RubberExpansionJoints #FactoryDirect

Conveyor Belts & Rollers

Looking for high-quality conveyor belts and rollers? Look no further than our factory! We offer top-quality products at competitive prices, ensuring your business runs smoothly.

Polyurethane Screening System

Looking for a durable and high-quality polyurethane screening system? Look no further than our factory! We produce top-notch products that will meet your needs. Order now! #PolyurethaneScreeningSystem #Factory

Flexible Metal Hose

Looking for high-quality flexible metal hoses? Look no further than our factory! We specialize in producing durable and reliable solutions for all your industrial needs.

Chemical Hose

Looking for top-quality chemical hose? Look no further than our factory! Our chemical hoses are engineered to handle a wide range of chemical applications safely and reliably. Shop now!

CVX Hydrocyclone Wear Parts

CVX Hydrocyclone Wear Parts - Factory direct spare and replacement components at competitive prices. Trust our experienced team for high-quality hydrocyclone parts. Order now!

AHR Slurry Pump Wear Parts

Looking for high-quality AHR Slurry Pump Wear Parts? Look no further! We are a factory that specializes in producing durable and reliable slurry pump wear parts. Contact us today.

Water hose

Looking for a reliable water hose? Look no further! Our factory produces high-quality hoses that are durable and efficient. Order now and experience the ultimate convenience of our water hose. #WaterHose #Factory #Reliable #Durable #Efficient

Custom Rubber & Plastic Products

Custom Rubber & Plastic Products - Factory Direct Prices. We specialize in manufacturing and supplying high quality rubber and plastic products. Contact us today for a quote! #custommanufacturing #factoryprices #rubberproducts #plasticproducts.

Air Hoses

Get reliable Air Hoses directly from our factory. Our expertly crafted hoses offer durable performance and assured quality. Shop now for seamless operations!

Pipe Valves

Looking for high-quality pipe valves? Look no further! Our factory produces premium valves at competitive prices. Contact us today for all your valve needs.

- Top Types of Expansion Joints - Wholesale Supplier from China

- Reviews

- Related Videos

Introducing our wide range of types of expansion joints designed to accommodate thermal movement, vibration, and pressure changes in piping systems. Our expansion joints are engineered with high-quality materials to ensure durability and long-lasting performance. We offer a variety of expansion joint types including single and double bellows, universal, gimbal, pressure balanced, and hinged, each designed to suit specific applications and operating conditions. Our expansion joints can accommodate axial, lateral, and angular movements in various directions. The single and double bellows expansion joints are compatible with most fluid mediums and are widely used in chemical plants, power plants, and water treatment facilities. Our universal expansion joints are ideal for systems with multiple directional movements, while our gimbal expansion joints can handle angular and axial movements. The pressure balanced expansion joints are designed to relieve the thrust forces caused by internal pressure and external forces, making them ideal for high-pressure and high-temperature systems. Our hinged expansion joints are perfect for applications with limited space and require quick assembly. All our expansion joints are manufactured to meet international standards and are rigorously tested to ensure their performance and reliability. Want to know which type of expansion joint is best suited for your application? Contact us today and let our experts guide you.

Expansion joints are essential in any construction project to avoid cracks or damage due to temperature changes, pressure, or seismic movements. There are various types of expansion joints available in the market such as metal, rubber, and fabric. When it comes to selecting the right expansion joint for your project, it's important to consider the nature of the movement, the type of structure, and the budget constraints. Some popular brands in the market include Mason Industries, Keflex, and Proco Products. It's always advisable to consult with a professional engineer to ensure that you are making the right choice for your project.

Expansion joints are an essential element in the construction world, providing flexibility and durability to structures to withstand environmental stress. There are various types of expansion joints for different applications such as thermal expansion joints, seismic joints, and building expansion joints. However, when it comes to selecting the right expansion joint for your project, it's crucial to consider factors like the application, material, and location. It's recommended to opt for expansion joints made of high-quality materials such as steel or rubber to ensure long-lasting performance and reduce the risk of failure. Overall, choosing the right type of expansion joint ensures the safety and longevity of the construction project.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours