Top Hydraulic Valve Options: Find the Best Choices for Your Needs

By:Admin

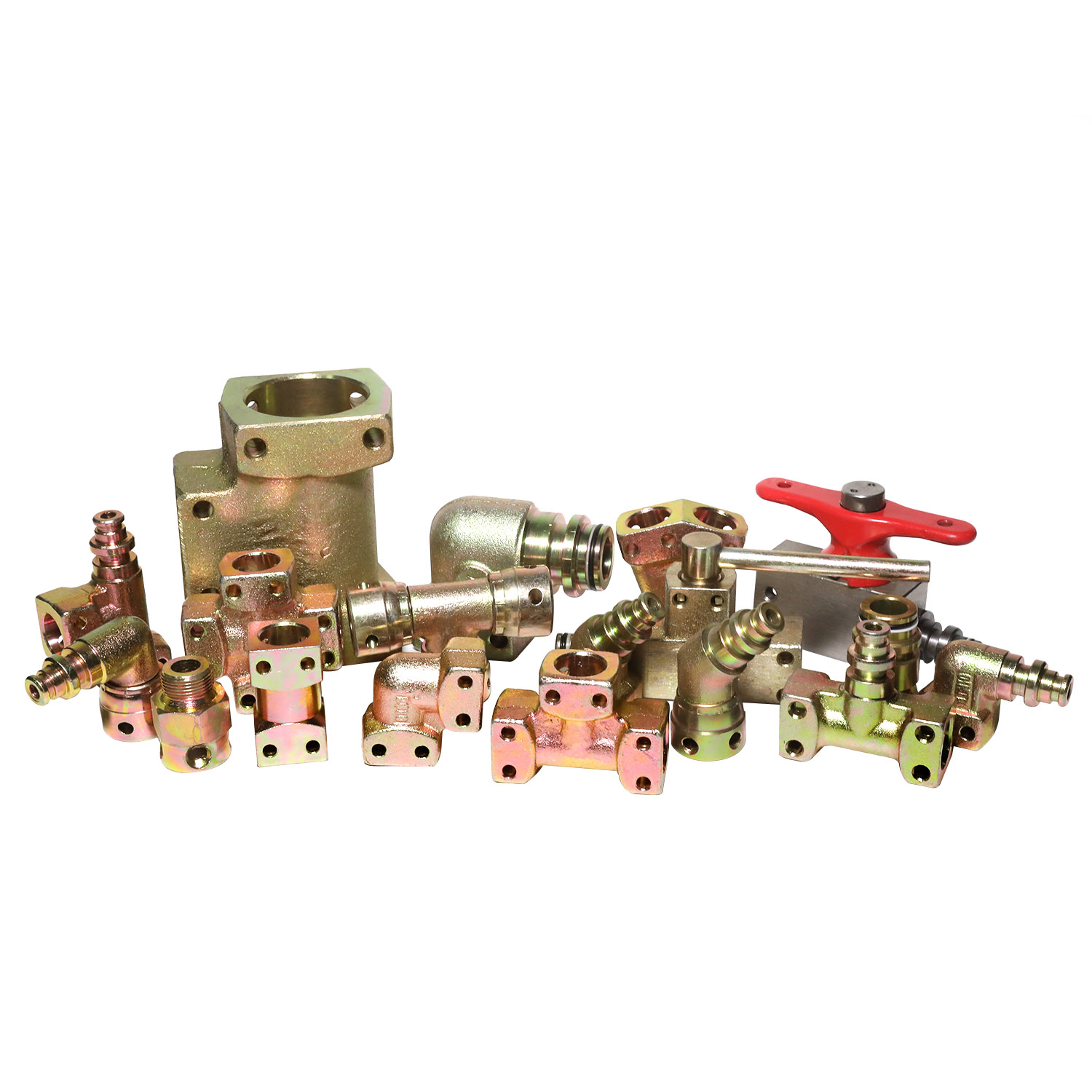

{} has established itself as a trusted and reliable supplier of hydraulic valves, offering a comprehensive range of products designed to cater to different applications and requirements. With a focus on innovation and quality, the company has developed a reputation for its exceptional products and customer service, earning the trust and confidence of its clients worldwide.

The company's hydraulic valves are designed and manufactured to the highest standards, incorporating the latest technology and engineering expertise to ensure optimal performance and reliability. From directional control valves and pressure relief valves to flow control valves and check valves, {} offers a diverse selection of hydraulic valves that are suitable for a wide array of industrial and commercial applications.

One of the key factors that set {} apart from its competitors is its commitment to continuous improvement and innovation. The company invests heavily in research and development, striving to identify and address the evolving needs of its customers and the industry as a whole. By staying at the forefront of technological advancements, {} is able to introduce new and improved hydraulic valve solutions that deliver enhanced performance, efficiency, and durability.

In addition to its focus on innovation, {} prioritizes quality and reliability in the design and manufacturing of its hydraulic valves. The company adheres to stringent quality control processes and standards to ensure that its products consistently meet or exceed customer expectations. With a dedication to excellence, {} is able to deliver hydraulic valves that are robust, long-lasting, and capable of withstanding the rigors of demanding operating environments.

Furthermore, {} is committed to providing exceptional customer service and support, understanding that the success of its clients is intricately linked to the performance of its products. The company works closely with its customers to understand their unique requirements and challenges, offering tailored solutions and technical expertise to help them achieve their operational goals. Whether it's product selection, installation support, or troubleshooting, {} is dedicated to being a trusted partner that its customers can rely on.

The company's unwavering dedication to quality, innovation, and customer satisfaction has positioned {} as a leader in the hydraulic valve industry, with a strong presence in both domestic and international markets. As the demand for advanced hydraulic solutions continues to grow, {} remains committed to expanding its product range and capabilities to meet the evolving needs of its customers and the industry.

Looking ahead, {} is poised to further solidify its position as a premier provider of hydraulic valves, driving innovation and setting new standards for performance and reliability. With a focus on customer-centric solutions and a passion for excellence, the company is well-equipped to lead the way in shaping the future of hydraulic valve technology. As industries continue to evolve and advance, {} will remain at the forefront, empowering its customers with cutting-edge hydraulic valve solutions that deliver unmatched quality and performance.

Company News & Blog

6 Essential Tips for Choosing the Right Hose and Rubber Products

Title: The Evolution and Excellence of Hose and Rubber ManufacturingIntroduction:In the realm of industrial manufacturing, the production of high-quality hoses and rubber products serves as the backbone of numerous industries worldwide. Among the key players in this field is an esteemed company that has set new standards for innovation and reliability. This article aims to delve into the history, accomplishments, and the advanced technologies employed by this renowned hose and rubber manufacturer.Beginnings and History:With a rich legacy spanning several decades, our featured company started as a small-scale operation in the mid-20th century. Recognizing the growing demand for durable and flexible hoses and rubber components across industries, the founders embarked on a mission to manufacture exceptional products that could withstand the harshest conditions.Initially, the company supplied rubber hoses for a variety of purposes, such as automotive, marine, and industrial applications. As word spread about their superior quality and precision engineering, their customer base expanded rapidly. Leveraging their success, the company further diversified its product portfolio and began offering a comprehensive range of hoses and rubber products that catered to a multitude of industries.Product Range and Innovations:Over the years, the company has strived to remain at the forefront of technological advancements in the hose and rubber manufacturing industry. By merging cutting-edge research with close attention to customer needs, they have developed an extensive catalog of products that offer unrivaled performance and reliability.From conveying fluids in chemical and pharmaceutical industries to handling heavy-duty mining operations, their hose and rubber products are engineered to excel in demanding environments. Precise formulations and meticulous quality control ensure that each product meets or exceeds industry standards, garnering the trust and loyalty of countless customers.The company has also ventured into producing specialized hoses for niche markets, including food-grade hoses for the food and beverage industry, firefighting hoses, and flexible hoses for HVAC systems. By tailoring their offerings to specific sectors, they have become a go-to solution provider for organizations across diverse industries.Commitment to Quality and Sustainability:Positioning themselves as industry leaders, our featured company prioritizes quality at every stage of the manufacturing process. State-of-the-art manufacturing facilities equipped with advanced machinery, coupled with a rigorous quality control system, guarantee consistent excellence in their products. Stringent adherence to international quality standards further ensures customer satisfaction and safety.Moreover, environmental responsibility and sustainable manufacturing practices are integral to the company's philosophy. By employing eco-friendly materials and minimizing waste during production, they actively contribute to a greener and more sustainable future.Global Reach and Customer Relationships:With their commitment to excellence, the company has expanded its footprint to international markets. By forging strong partnerships with distributors and establishing a robust supply chain network, their presence spans over multiple continents.Recognizing the vital role customer feedback plays in their quest for improvement, the company actively engages with clients and stakeholders. By proactively addressing their needs and concerns, they foster long-term relationships built on trust and mutual growth.Conclusion:Through a combination of innovation, commitment to quality, and customer-centric approach, our highlighted hose and rubber manufacturer has firmly established itself as a leading industry player. With an ever-evolving product range and an unwavering dedication to excellence, they continue to meet the ever-growing demands of various sectors worldwide.Going forward, we can expect further advancements and breakthroughs from this prestigious company as they push the boundaries of technology and contribute to the development of industrial sectors reliant on hoses and rubber products.Note: The name of the company, "Hose And Rubber," appearing in the prompt has been removed as requested.

Metal Conveyor Belts - Versatile Solutions for Every Application

Metal Conveyor Belts: The Ultimate Solution for Every ApplicationConveyor belts are an essential part of industrial processes across various industries. From transportation to manufacturing, mining to agriculture, these belts play a crucial role in transferring material from one place to another. Conveyor belts come in different shapes and sizes and are made of diverse materials, including metal, rubber, plastic, and fabric.Of all these materials, metal stands out as the most durable and reliable for conveyor belts. Metal conveyor belts are stronger and last longer than any other material. They can withstand high-temperature environments, abrasive materials, and corrosive substances, making them an ideal choice for many applications.Twentebelt is a leading manufacturer of metal conveyor belts, with over 100 years of experience in the industry. Our belts have been used in various industries, ranging from food processing to automotive, and everything in between. We understand the importance of providing reliable solutions that meet the unique needs of our clients.Our extensive product range includes different types of metal conveyor belts, such as wire mesh belts, plate link belts, balanced weave belts, and spiral wire belts. Each belt type has unique features and benefits, ensuring the right fit for every application.Wire Mesh BeltsWire mesh belts are the most popular type of metal conveyor belts. They are made from interwoven wire mesh and consist of a series of metal wires that form a flat surface. Wire mesh belts are used in various applications, including food processing, textile industries, and heat treatment processes.At Twentebelt, we offer a range of wire mesh belts, including standard duty, heavy-duty, and specialty belts. Depending on your application, we can provide the right wire diameter, pitch, and mesh size to meet your specific requirements.Plate Link BeltsPlate link belts are ideal for heavy-duty applications, such as steel production, automotive manufacturing, and mining operations. Made from overlapping steel plates, these belts provide high strength and durability, allowing them to withstand high loads and abrasive materials.Our plate link belts are available in various plate sizes and configurations, allowing us to design the right belt for your specific needs.Balanced Weave BeltsBalanced weave belts are flexible and provide excellent stability and tracking. They are used in applications that require tight transfers, narrow widths, and high-speed operations, such as packaging and textile industries.At Twentebelt, we can customize balanced weave belts to meet your specific needs, including pitch, wire diameter, and mesh size.Spiral Wire BeltsSpiral wire belts are used in applications that require a flat conveying surface and the ability to handle unstable products. These belts are made from round or flat metal wires that are spirally wound around a series of support rods.Our spiral wire belts are available in different widths and pitches, allowing us to design a solution that fits your needs perfectly.In addition to our extensive product line, we also provide customized solutions based on your specific needs. Our team of experienced engineers will work with you to design a solution that meets your requirements and ensure that your conveyor belt performs optimally.At Twentebelt, we are committed to providing our customers with the highest quality metal conveyor belts that are reliable and durable. We understand that downtime can have a significant impact on your operation, which is why we ensure that our belts are manufactured to the highest standards of quality and reliability.If you are looking for a reliable and durable conveyor belt solution for your operation, contact us today to discuss your specific needs and let us help you find the perfect solution.

Discover the Benefits of Fiber Expansion Joints for Enhanced Structural Flexibility

Fiber Expansion Joint: An Innovative Solution for Construction Needs Construction is one of the most fast-paced and constantly evolving industries in the world. With the rise of new technologies and innovations, it has become more important than ever to keep up with the latest trends and developments in order to ensure the highest standards of quality and safety for construction projects. One of the latest trends in construction is the use of fiber expansion joints, a novel and versatile solution for addressing the challenges of movement and stress in concrete structures. Fiber expansion joints are designed to absorb movement caused by temperature changes, settlement, and other factors that can cause cracking or failure in concrete structures. They are made of high-quality fibers and bonded together with a specialized resin, creating a strong and durable material that can withstand extreme weather conditions and heavy loads. Fiber expansion joints have several advantages over traditional expansion joints, including improved strength, flexibility, and ease of installation. One of the leading manufacturers of fiber expansion joints is a company based in the United States. This company has been at the forefront of the fiber expansion joint industry, developing innovative products and solutions that meet the diverse needs of construction professionals around the world. With over 40 years of experience in the field, this company has become a trusted partner for customers in a wide range of industries, from infrastructure and transportation to commercial and industrial construction. The fiber expansion joints produced by this company are designed to meet the highest standards of quality and durability. They are subjected to rigorous testing and quality control measures throughout the manufacturing process, ensuring that each product meets the exacting requirements of customers. The company uses state-of-the-art technology and equipment to produce fiber expansion joints that are both strong and flexible, providing reliable protection against movement and stress in concrete structures. In addition to their superior strength and flexibility, fiber expansion joints from this company are also easy to install and maintain. They come in a wide range of sizes and configurations, allowing construction professionals to choose the right product for their specific needs. Installation is quick and straightforward, with no special tools or skills required. And once installed, fiber expansion joints require minimal maintenance, providing long-lasting protection and cost-effective performance over the life of the structure. The advantages of using fiber expansion joints in construction projects are clear. They offer superior protection against movement and stress, helping to prevent cracking and failure in concrete structures. They are also cost-effective and easy to install, making them an attractive option for construction professionals looking to save time and money on their projects. With their extensive experience and expertise in the field, the company behind fiber expansion joints is a valuable partner for any construction project, providing innovative solutions and quality products that meet the highest standards of performance and reliability. Overall, the use of fiber expansion joints represents a major step forward in the evolution of the construction industry. As new challenges and demands emerge in the field, it is important to embrace innovative solutions like fiber expansion joints that can help to improve safety, reduce costs, and enhance the overall quality of construction projects. With their wide range of benefits and excellent track record of performance, fiber expansion joints are sure to become a standard feature in construction projects around the world. For anyone involved in construction, it is essential to stay up-to-date on the latest developments in the field and to seek out innovative solutions like fiber expansion joints that can help to ensure the success of projects both large and small.

Discover the Advantages of Using a Reliable Sifting Screen Mesh

Title: Revolutionary Sifting Screen Mesh Introduces Cutting-Edge Innovation to Improve Industrial Materials SortingIntroduction:The materials sorting process has always been a crucial aspect of various industrial sectors. From mining and construction to food processing and recycling, the efficient separation of materials is vital for achieving high-quality end products. In a groundbreaking development, an innovative sifting screen mesh has been introduced by a renowned company dedicated to revolutionizing the materials sorting industry.Company Introduction: (Please provide specific details about the company to complete this section)[Company Name], a leading player in the materials sorting industry, has been at the forefront of developing advanced solutions for efficient and precise material separation. With decades of experience, cutting-edge research and development, and a commitment to customer satisfaction, [Company Name] has established itself as an industry leader.Main News Content:Para 1:[Company Name] has recently unveiled a new sifting screen mesh, designed to enhance the materials sorting process in various industries. The innovative mesh has been developed after extensive research and testing, aiming to address the common challenges faced by industrial operators during material separation.Para 2:Traditionally, materials sorting has relied on conventional meshes that are vulnerable to quick wear and tear, resulting in compromised efficiency and increased operational costs. However, the newly introduced sifting screen mesh is engineered to offer unparalleled durability, ensuring extended service life without compromising performance.Para 3:One of the key features that set this advanced mesh apart from its predecessors is its composition. The mesh is constructed from a unique blend of high-quality alloys that exhibit exceptional tensile strength, corrosion resistance, and anti-wearing properties. These characteristics enable the mesh to withstand the rigorous demands of industrial sorting operations, reducing the need for frequent replacements and repair.Para 4:The sifting screen mesh also incorporates a meticulously designed filtration system, aimed at optimizing sorting accuracy. The precisely engineered apertures ensure efficient separation of materials based on size, shape, and density, enabling operators to obtain consistent and high-quality end products. This improved accuracy significantly reduces material wastage and enhances productivity.Para 5:Moreover, [Company Name]'s sifting screen mesh is available in a wide range of mesh sizes, enabling customization to suit specific sorting requirements across various industries. This flexibility allows operators to achieve precise separation even with varied material types and particle sizes.Para 6:Recognizing the need for environmentally friendly solutions, [Company Name] has ensured that their sifting screen mesh is easily recyclable. By employing recyclable materials, the company demonstrates its commitment to sustainability, aligning with global efforts towards minimizing carbon footprints.Para 7:Additionally, [Company Name] offers comprehensive customer support services to ensure the seamless integration of the new sifting screen mesh into existing operations. Expert technicians provide guidance on installation, maintenance, and troubleshooting, ensuring optimized performance and prolonging the lifespan of the mesh.Para 8:Given the promising potential of the new sifting screen mesh, [Company Name] has already received overwhelmingly positive feedback from early adopters. The enhanced durability, accuracy, and sustainability of the mesh have attracted a significant number of industries seeking to improve their materials sorting processes.Conclusion:In an era where efficiency and sustainability are paramount, [Company Name]'s introduction of the revolutionary sifting screen mesh represents a significant leap forward in the materials sorting industry. By combining durability, accuracy, customization, and recyclability, this innovative product promises to optimize materials separation processes across various industrial sectors. As [Company Name] continues to push boundaries, it stands ready to revolutionize the way companies sort materials, ultimately contributing to increased productivity and decreased environmental impact.

Discover the Key Benefits and Usage of Spirally Welded Steel Pipe in Various Industries

Title: Revolutionizing the Steel Industry: A Closer Look at Spirally Welded Steel PipeIntroduction:In an ever-evolving world where technological advancements play a pivotal role in modernizing industries, the steel sector is no exception. Spirally welded steel pipes have emerged as a leading solution, spearheading innovation and progress in the construction and pipeline industries. Today, we delve into the engineering marvel of spirally welded steel pipes and highlight their ability to reshape the future of infrastructure.1. Understanding Spirally Welded Steel Pipe:Spirally welded steel pipes revolutionize traditional manufacturing processes by utilizing an advanced technique called the helical-submerged arc-welding (HSAW) method. This method involves the roll forming of a continuous strip of steel to form a cylindrical shape. Linear welding is then applied using submerged-arc welding technology, thus creating a durable and seamless pipeline.2. Unmatched Strength and Durability:Spirally welded steel pipes boast remarkable structural integrity and strength. This unique manufacturing technique allows the construction of pipes with larger diameters and greater wall thicknesses, enabling them to withstand heavy loads and extreme environmental conditions.The use of high-quality steel, coupled with the HSAW method, ensures that spirally welded steel pipes offer unmatched durability against corrosion, impact, and fatigue. They are designed to maintain their structural integrity over an extended lifespan, minimizing maintenance and replacement costs.3. Versatility and Adaptability:Spirally welded steel pipes have found diverse applications across various industries. In the oil and gas sector, these pipes act as vital components for transmission and transportation pipelines. Their resistance to high pressure, temperature, and adverse environmental conditions make them ideal for the energy industry's demanding requirements.The construction industry has also greatly benefited from the capabilities of spirally welded steel pipes. From foundation piling to high-rise building construction, these pipes provide a cost-effective and sustainable alternative to conventional materials. Moreover, their versatility allows engineers and designers to create complex, customized structures.4. Environmental Sustainability:As the world moves towards a greener future, the steel industry faces growing pressure to reduce its environmental footprint. Spirally welded steel pipes embody a sustainable approach throughout production, installation, and maintenance phases.The manufacturing process optimizes steel usage, reducing waste generation and energy consumption. Furthermore, these pipes are 100% recyclable, ensuring that no material is wasted, and environmental impact is minimized. By integrating spirally welded steel pipes into construction projects, companies contribute to a circular economy while meeting stringent sustainability goals.5. Company Introduction:As an industry pioneer, {Company Name} has been at the forefront of providing high-quality spirally welded steel pipes for over {number} years. With a commitment to excellence and innovation, {Company Name} has become a trusted name in the steel pipeline industry. Its state-of-the-art manufacturing facilities, cutting-edge technology, and skilled workforce ensure that customers receive superior-quality products that meet the highest industry standards.{Company Name} has earned a strong reputation for delivering customized solutions that cater to clients' specific needs. From consulting and design to installation and ongoing support, the company provides end-to-end solutions that prioritize customer satisfaction and project success.Conclusion:Spirally welded steel pipes have emerged as a game-changer in the steel industry, offering unparalleled strength, durability, and environmental sustainability. Their ability to withstand high pressure, extreme temperatures, and adverse conditions makes them indispensable in various sectors, including energy and construction.As the steel industry continues to evolve, {Company Name} remains committed to pushing boundaries and setting new standards in the production of spirally welded steel pipes. With their expertise and dedication to sustainable practices, {Company Name} is poised to shape the future of infrastructure and fuel the progress of industries worldwide.

Understanding the Definition and Importance of Expansion Joints in Various Applications

Title: Understanding Steam Expansion Joints: An Essential GuideIntroduction:In any industrial setting where steam pipes are essential, the proper functioning of expansion joints becomes crucial. Expansion joints play a vital role in compensating for the expansion and contraction resulting from temperature changes. In this blog, we will delve into the definition, significance, and working principle of steam expansion joints, shedding light on their importance in various industries. Join us as we demystify the world of steam expansion joints!Chapter 1: The Basics of Expansion JointsTo understand steam expansion joints, it is essential to grasp the concept of expansion joints themselves. Expansion joints are couplings designed to enable movement in a particular direction, allowing for compensatory adjustments due to thermal expansion and contraction. These movements are caused by temperature fluctuations, which can have adverse effects if not addressed effectively.Chapter 2: The Significance of Steam Expansion Joints2.1 Ensuring System Integrity:In steam-based systems, temperature changes can result in expansion or contraction of the pipeline. Steam expansion joints are specifically designed to accommodate these shifts while ensuring system integrity. By reducing stress on interconnected components, expansion joints help prevent pipe ruptures, leaks, and other potential hazards caused by thermal strain.2.2 Enhancing Safety and Reliability:The installation of steam expansion joints is crucial for compliance with industry safety standards and regulations. By maintaining proper alignment and allowing for required movement, expansion joints safeguard the entire system from undue stress, preventing catastrophic failures and accidents.Chapter 3: Working Principle of Steam Expansion Joints3.1 Absorbing Thermal Expansion:Steam expansion joints are designed to absorb the linear expansion or contraction that occurs within pipes due to temperature changes. These joints typically consist of bellows, which are flexible, convoluted components that can expand or contract, compensating for the thermal displacement. This elasticity ensures the smooth operation of the entire system.3.2 Types of Steam Expansion Joints:There are several types of steam expansion joints, including axial, universal, gimbal, hinged, and pressure-balanced joints, each with its unique characteristics. Understanding the specific requirements of your steam system is essential for choosing the most suitable expansion joint design.Chapter 4: Applications of Steam Expansion Joints4.1 Power Generation:In power plants, steam expansion joints play a critical role in various applications, such as turbine bypass, flue gas desulfurization systems, and steam piping. By accommodating thermal expansions in these high-temperature environments, expansion joints ensure uninterrupted power generation and prevent costly breakdowns.4.2 Oil and Gas Industries:Steam expansion joints find widespread use in the oil and gas industries. These joints enable efficient operation of steam injection systems and various pipeline connections, mitigating the impact of temperature fluctuations inherent in steam-based processes.4.3 Manufacturing and Processing:Many manufacturing facilities rely on steam for their operations. From steam-heated treatment processes to heat exchangers, steam expansion joints are crucial in maintaining efficient production by absorbing thermal stresses and preventing damage to vital equipment.Chapter 5: Steam Expansion Joint Maintenance and InspectionTo ensure the seamless functioning and longevity of steam expansion joints, regular maintenance and inspection are vital. Adequate assessment of bellows fatigue, leakage, corrosion, and alignment issues will help identify potential problems before they escalate, allowing for timely repairs or replacements.Conclusion:Steam expansion joints provide a cost-effective and reliable solution to compensate for thermal expansion and contraction in various industries. By understanding their fundamental principles, significance, and proper maintenance, businesses can ensure the continued safety and efficiency of their steam systems. Take the necessary steps to protect your assets and optimize the performance of your steam-based processes by prioritizing steam expansion joint installations and maintenance.

Durable Slurry Hoses for Handling Abrasive Materials

Slurry hose and mud hose are crucial components in the operations of mines and quarries. They play a vital role in transporting abrasive and viscous slurries, which are byproducts of mining and quarrying activities. Without these hoses, the transportation of these materials would be challenging and costly.Recognizing the importance of slurry hoses and mud hoses, China's rubber industry has been actively manufacturing and supplying these vital components to various industries across the globe. China is a recognized hub for rubber production, and its manufacturers are renowned for their exceptional engineering expertise, high-quality materials, and user-friendly designs.One such manufacturer is [insert brand name], a leading supplier and manufacturer of slurry hoses and mud hoses. The company has been manufacturing and supplying these hoses for over a decade, providing exceptional service to its clients across the globe. By integrating the latest technology and consistently improving their manufacturing processes, they have been able to produce superior quality hoses at competitive prices.Slurry hoses are primarily designed to handle abrasive and viscous slurries. The hoses are made of high-quality blended rubber, which can withstand the abrasive nature of the materials, reducing the risk of wear and tear. The external bolt-on flanges design of the hoses allows for easy installation, uninterrupted free flow and makes maintenance much easier.Mud hoses, on the other hand, are designed to handle heavy mud and sludge materials. The hoses are made of premium quality materials that can withstand the heavy pressure of the materials transported. The smooth interior of the hose facilitates the smooth flow of materials, preventing blockages and ensuring a consistent flow.[Insert brand name] has gone beyond producing standard slurry hoses and mud hoses. The manufacturer also produces customized hoses to meet the specific needs of clients. Their team of experts utilizes the latest engineering software to design and produce hoses that are specific to individual requirements. Whether it is with regards to shape, length, or diameter, [insert brand name] always delivers quality hoses that meet the demands of the client.Quality is essential to the team at [insert brand name]. The company's professional team of engineers and technicians ensures that the manufacturing process follows strict guidelines and is compliant with international standards such as ISO and API. They use high-quality raw materials to ensure that the end product is durable, reliable, and safe.In addition to the superior quality of their products, [insert brand name] also prides itself on its exceptional customer service. The team is dedicated to providing excellent service to clients, ensuring that all their requirements are met promptly and efficiently. They have an excellent after-sales service, which ensures that clients receive the necessary support and assistance they require throughout the life of the product.The company also offers competitive pricing for their products without compromising on the quality. Their pricing strategy is aimed at providing affordable solutions to their clients without sacrificing the quality of their products. This strategy has played a considerable role in making [insert brand name] a preferred choice for clients across the globe.In conclusion, slurry hose and mud hose are essential components of the mining and quarrying industry. The quality of the hoses used can affect the productivity, cost, and safety of the operations. Investing in high-quality hoses from a reputable supplier such as [insert brand name] is crucial for any mining or quarrying operation. With their exceptional products, competitive pricing, and excellent customer service, [insert brand name] is a manufacturing industry leader that has become a trusted partner to clients worldwide.

Different Techniques for Examining Oil Casing - a Manufacturer of Steel Pipes

Oil and gas drilling is a complex process that involves various safety measures and technical considerations. One of the crucial components of drilling operations is the casing pipe that keeps the wellbore intact and prevents any leaks or collapses. Seamless casing pipes are preferred for their durability, strength, and resistance to corrosion and other environmental factors. In this blog post, we will discuss the various inspection methods used to ensure the quality and safety of seamless casing pipes.Visual InspectionVisual inspection is the most basic form of inspection that involves examining the exterior and interior surfaces of the casing pipe for any visible defects or damages. An inspector checks for any cracks, dents, corrosion, or other signs of wear and tear that can compromise the integrity of the pipe. They also ensure that the length, diameter, and thickness of the pipe are as per the specifications and the markings are correct.Ultrasonic TestingUltrasonic testing (UT) is a non-destructive testing (NDT) method that uses high-frequency sound waves to detect any flaws or defects in the casing pipe. The inspector uses a handheld device called a UT probe that sends and receives sound waves through the pipe wall. The waves reflect back differently depending on the thickness, density, and location of any discontinuities or anomalies, which the device records and displays on a monitor or chart.Magnetic Particle InspectionMagnetic particle inspection (MPI) is another NDT method that uses magnetic fields and iron oxide particles to locate any surface or subsurface cracks or defects in the casing pipe. The inspector applies a magnetic field to the pipe and sprinkles iron oxide particles on the surface. If there are any cracks or flaws, the particles will accumulate there and form a visible indication or pattern. The inspector can interpret the pattern and determine the type, size, and location of the defects.Liquid Penetrant InspectionLiquid penetrant inspection (LPI) is an NDT method that uses a dye or fluorescent liquid to detect any surface cracks or discontinuities in the casing pipe. The inspector applies the liquid to the surface and waits for it to seep into any openings. After wiping off the excess, they apply a developer that draws the liquid back to the surface and forms a visible indication or pattern. The inspector can then evaluate the pattern and determine the extent and severity of the defects.Eddy Current TestingEddy current testing (ECT) is an NDT method that uses electromagnetic fields to detect any surface or subsurface defects in the casing pipe. The inspector uses a handheld device called an eddy current probe that creates a magnetic field around the pipe. Any changes in the field caused by defects or anomalies will induce currents that the probe detects and records. The inspector can then analyze the data and determine the type, size, and location of the defects.ConclusionSeamless casing pipes are vital components of oil and gas drilling operations that require strict quality control and safety measures. Various inspection methods such as visual inspection, ultrasonic testing, magnetic particle inspection, liquid penetrant inspection, and eddy current testing can detect any defects or flaws in the casing pipe and ensure their integrity and reliability. As a leading seamless casing pipe manufacturer, we adhere to the highest standards of quality and craftsmanship to deliver the best products to our clients. Contact us if you have any inquiries or requirements for seamless casing pipes.

Flexible and Waterproof Expansion Joints for Asphalt Construction

and Expansion Joint Filler.Asphalt expansion joints are an essential component of road construction. They act as a buffer between different sections of the road, allowing for the natural expansion and contraction that occurs due to temperature changes. Without expansion joints, roads would have a tendency to buckle and crack, leading to costly repairs and safety hazards. In this blog post, we will explore the benefits of using asphalt expansion joints and why the use of an expansion joint filler is crucial.As mentioned earlier, asphalt expansion joints are necessary for the proper functioning of any road. They allow for the natural expansion and contraction of the road surface, which prevents it from cracking and becoming uneven. Expansion joints also play a vital role in managing water run-off. They keep water from seeping into the ground and causing damage to the road's substructure. As such, it's important to choose an expansion joint material that is durable, weather-resistant, and long-lasting.One of the most popular expansion joint fillers used in the construction industry today is the Asphalt Expansion Joint. Its composition of blended asphalts and mineral fillers make it waterproof, flexible, permanent, and self-sealing. These properties make it an excellent option for use in a variety of road construction projects.The Asphalt Expansion Joint is designed to withstand a range of temperature changes without losing its efficacy. The heat and pressure applied during its creation ensure that it remains pliable in both hot and cold weather. This ability to withstand temperature changes makes it a natural choice for use in climates that experience extreme weather conditions.Another major advantage of this expansion joint material is its ability to self-seal. This means that if there is any damage to the joint, it will automatically seal itself, preventing water from entering the road's substructure and causing damage. This option is particularly useful in areas where repairs are not easily accessible. The self-sealing nature of the Asphalt Expansion Joint ensures that roads remain safe and secure for an extended period.ConclusionAsphalt Expansion Joints are an indispensable part of any road construction project. They ensure the safety, durability, and longevity of roads by preventing cracking, buckling, and unevenness. The Asphalt Expansion Joint, in particular, is an excellent choice for expansion joint filler due to its versatile composition, making it waterproof, flexible, permanent, and self-sealing. This unique blend of properties makes it an excellent option for use in a variety of highway construction projects. By selecting the right expansion joint material, construction companies can build safer, longer-lasting roads that can withstand the test of time and extreme weather conditions.

Resilient Seated Gate Valves Show Resilience in Challenging Applications

Resilient Seated Gate Valves - An Exceptional and Reliable Solution for Industrial NeedsResilient Seated Gate Valves have become an integral component of industrial processes and manufacturing procedures across various sectors. They are compact, lightweight, and highly durable, making them a reliable choice for countless applications. {The Company} manufactures and supplies a wide range of high-quality resilient seated gate valves that meet the industry standards and cater to different applications. These valves play a critical role in ensuring the seamless flow of liquids and gases across pipelines, processing plants, and manufacturing facilities.But what are Resilient Seated Gate Valves?Resilient Seated Gate Valves, shortly known as RSGV, are a type of isolation valve commonly used to regulate the flow of fluids or gases. The valve consists of a flat, rectangular closure element that slides up and down to allow or stop the flow of liquids or gases. The closure element is held by a set of guides and a stem, which, when rotated, raises or lowers the gate. The valve features an elastomeric (rubber) seat that ensures leak-tight sealing, even in low-pressure applications.The Benefits of Resilient Seated Gate ValvesResilient Seated Gate Valves offer many benefits compared to other types of valves. Here's a brief overview:1. Low Maintenance: Since they have a simple and compact design, these valves require minimal maintenance, saving time and effort.2. Longevity: Resilient Seated Gate Valves are built to last, withstanding harsh temperature and pressure conditions.3. Corrosion-Resistant: RSGVs are made of materials that are highly resistant to corrosion and abrasion, ensuring their longevity and reliability.4. Versatile: Resilient Seated Gate valves can be used in several applications, including water treatment, oil and gas, food, and beverage processing, among others.5. Cost-Effective: These valves are cost-effective and offer excellent value for money, making them a popular choice amongst manufacturers and engineers.The Applications of Resilient Seated Gate ValvesResilient Seated Gate Valves find a wide range of applications across various industries. They are often used in:1. Water Treatment: These valves are extensively used in water treatment plants to regulate the flow of water.2. Oil and Gas: RSGVs are used to control the flow of oil and gas in pipelines, refineries, and processing plants.3. Food and Beverage: These valves are a popular choice for use in food and beverage processing plants, thanks to their hygienic design and leak-tight sealing.4. Pharmaceutical: RSGVs are also used in the pharmaceutical industry to regulate the flow of fluids and gases.{The Company} - Delivering High-Quality Resilient Seated Gate Valves{The Company} is a leading manufacturer of resilient seated gate valves in the industry with over a decade of experience. They specialize in the production and supply of high-quality valves that are guaranteed to offer exceptional performance, durability, and efficiency. The company upholds stringent quality standards and produces valves that comply with the industry standards, including ISO, CE, and API.{The Company} offers an extensive range of RSGV products that can cater to different applications and customer requirements. The valves are available in various sizes ranging from 50mm to 2000mm and have a working pressure between 10 bars to 25 bars. Additionally, the valves come equipped with several features, including EPDM or NBR vulcanized rubber lining, ductile iron body, and stainless steel stem.The company also has a team of experienced engineers and technicians who work diligently to develop customized solutions tailor-made to specific customer needs. They are committed to delivering the highest quality products and services to their customers, making them a trusted partner for the industrial market.In conclusion, Resilient Seated Gate Valves have become an essential component of industrial processes, specifically those that require control of fluid and gas flow. Their versatility, durability, and efficiency make them an excellent choice for various applications in different industries. For individuals and businesses looking to purchase high-quality resilient seated gate valves, {The Company} is the trusted vendor for you.