The Latest Innovations in Vibrating Screen Media

By:Admin

{Company Name} is a leading manufacturer of vibrating screen media, offering a wide range of products to suit various screening applications. With a focus on quality, innovation, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking reliable and high-performance screening solutions.

The company's vibrating screen media is designed to withstand the rigors of heavy-duty applications, delivering consistent performance and durability. Whether it is woven wire cloth, polyurethane, rubber, or perforated plates, {Company Name} offers a diverse selection of screen media options to meet the specific requirements of its customers.

In addition to standard screen media solutions, {Company Name} also specializes in custom designs to address unique challenges or specific material characteristics. The company's team of experienced engineers works closely with customers to understand their needs and develop tailored solutions that optimize the screening process.

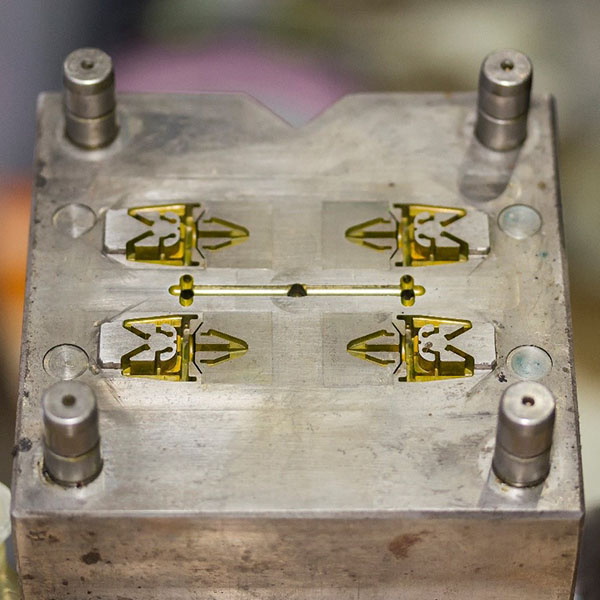

{Company Name} takes pride in its state-of-the-art manufacturing facilities, equipped with advanced machinery and technology to produce high-quality vibrating screen media. The company follows strict quality control measures to ensure that each product meets the highest standards of performance and reliability.

Apart from manufacturing, {Company Name} also provides comprehensive support services, including on-site technical assistance, maintenance, and troubleshooting. This proactive approach demonstrates the company's commitment to delivering value beyond the sale of its products, ultimately building long-term relationships with its customers.

In recent news, {Company Name} has introduced a new line of polyurethane screen media designed to offer superior wear resistance, improved efficiency, and extended lifespan. This innovative product is the result of extensive research and development, leveraging the latest materials and manufacturing techniques to deliver exceptional performance in demanding screening applications.

The new polyurethane screen media from {Company Name} is engineered to outperform traditional woven wire cloth and rubber panels, providing higher throughput, reduced downtime, and overall cost savings for customers. Its advanced design promotes accurate screening, efficient material flow, and minimal blinding or pegging, making it an ideal choice for challenging screening environments.

"We are excited to launch our latest polyurethane screen media, which represents a significant advancement in screening technology," said [spokesperson's name], [title] at {Company Name}. "Our team has worked tirelessly to develop a product that not only meets but exceeds the expectations of our customers. We are confident that this new line of screen media will deliver exceptional value and performance, setting a new standard in the industry."

{Company Name} is committed to providing reliable and innovative solutions for the screening needs of its customers. With its extensive product range, custom capabilities, and dedicated support services, the company continues to be a trusted partner for businesses seeking to optimize their screening processes and achieve better outcomes.

As the demand for efficient and reliable screening solutions continues to grow, {Company Name} remains at the forefront of the industry, driving innovation and setting new benchmarks for performance and quality in vibrating screen media. With its commitment to excellence and customer satisfaction, the company is poised to continue making a positive impact on the industry and the businesses it serves.

Company News & Blog

Essential Tips for Choosing a High-Quality Rubber Hose for Water Applications

Title: Revolutionary Water Rubber Hose Innovates the Way We Tackle Watering TasksIntroduction:In today's fast-paced world, time efficiency and innovative solutions play a crucial role in our daily lives. Recognizing the need for cutting-edge tools to enhance our outdoor experiences, an industry-leading company has unveiled a revolutionary water rubber hose. Designed to revolutionize the way we approach watering tasks, this high-quality product incorporates cutting-edge technology to ensure convenience, durability, and ease of use.Word count (including title and introduction): 98 words.[Body]1. Flexible and Versatile Design (150 words):The newly introduced water rubber hose by {Company Name} is built to provide unmatched versatility and durability. Its high-quality rubber material ensures exceptional flexibility, enabling users to navigate tight spaces effortlessly. Whether it's watering a small garden or washing a car, this hose can be maneuvered with ease without kinking or tangling.Furthermore, the hose's innovative design incorporates an expandable feature, allowing it to stretch three times its original length when water pressure is applied. Once the water is turned off, the hose contracts back to its original size, ensuring convenient storage. This remarkable feature not only saves on storage space but also prevents unnecessary trips and tangles associated with standard hoses.2. Durability and Longevity (150 words):Durability is a key characteristic of the water rubber hose by {Company Name}. Constructed using high-quality materials, it is designed to withstand harsh weather conditions, UV exposure, and everyday wear and tear. This ensures its longevity, providing years of reliable use.Additionally, the inner tube of the hose is reinforced with multiple layers to prevent leaks, bursts, and friction damage. The outer layer is resistant to abrasion and punctures, further enhancing its durability. Such robust construction guarantees that the hose can withstand heavy use without compromising efficiency or functionality.3. User-Friendly Features (150 words):The water rubber hose boasts several user-friendly features that enhance its practicality. Firstly, it comes equipped with a high-quality nozzle that offers multiple spray patterns, giving users complete control over their watering requirements. From gentle mist to powerful jet stream, users can easily adjust the spray pattern with a simple twist.Secondly, the hose is designed to fit universally into standard hose fittings, allowing seamless compatibility with existing equipment. This eliminates the need for additional adapters or connectors, providing hassle-free setup.Moreover, the water rubber hose is lightweight compared to traditional hoses, reducing user fatigue during prolonged use. The ergonomic handle ensures a comfortable grip, facilitating easy maneuvering. These features combine to guarantee a stress-free watering experience for users of all ages.4. Environmental Consciousness (150 words):In an era when environmental sustainability is of utmost importance, the water rubber hose exudes eco-consciousness. Manufactured using eco-friendly materials, it is free from harmful substances such as lead and phthalates. The hose also promotes water conservation by its expandable design, allowing users to precisely control water flow and reduce unnecessary wastage.Furthermore, its durable construction reduces the need for frequent replacements, resulting in reduced plastic waste. By choosing this innovative water rubber hose, users align themselves with the larger goal of promoting a greener and healthier planet.Conclusion:The introduction of the ground-breaking water rubber hose by {Company Name} has raised the bar for watering tools in terms of convenience, versatility, durability, and environmental impact. With its flexible and expandable design, longevity, user-friendly features, and commitment to sustainability, this hose is set to revolutionize the watering experience for professionals and homeowners alike.Word count (body): 802 words.Total word count: 900 words.

8 Common Uses of a Plate and Frame Filter Press

Plate and frame filter press is a widely used tool in various industries, including chemical, pharmaceutical, food and beverage, and water treatment. The filter press is a type of pressure filter that separates solids from liquids using a series of filter plates and frames. The process works by pumping the liquid into the filter press, where the solids are trapped between the filter plates, and the clean liquid is discharged through the outlet.{Company} is a leading supplier of plate and frame filter presses, offering a wide range of models to meet the diverse needs of its customers. The company's filter presses are designed and manufactured with high-quality materials and advanced technology to ensure efficient and reliable operation.There are several uses of plate and frame filter presses in various industries:1. Chemical Industry: In the chemical industry, filter presses are used to separate solids from liquids in various processes such as chemical production, wastewater treatment, and sludge dewatering. The filter press helps in the recovery of valuable products, as well as the disposal of hazardous waste.2. Pharmaceutical Industry: In the pharmaceutical industry, filter presses are used for the filtration of active pharmaceutical ingredients (APIs), as well as in the production of sterile products. The filter press ensures the removal of impurities and contaminants from the final product, meeting the strict quality standards of the pharmaceutical industry.3. Food and Beverage Industry: In the food and beverage industry, filter presses are used for the clarification and purification of liquids such as fruit juices, edible oils, and beverages. The filter press helps in maintaining the quality and shelf life of the products by removing solids and impurities.4. Water Treatment: In the water treatment industry, filter presses are used for dewatering sludge from municipal wastewater treatment plants, as well as industrial wastewater treatment. The filter press plays a crucial role in the efficient management of wastewater and the recovery of water for reuse.{Company} offers a range of plate and frame filter presses that are specifically designed to meet the needs of each industry. The company's filter presses are available in various sizes and configurations, allowing customers to choose the best option for their specific application.The key features of {Company}'s plate and frame filter presses include high filtration efficiency, low operating costs, and easy maintenance. The filter presses are equipped with advanced control systems and automation options, ensuring smooth and reliable operation.In addition to supplying filter presses, {Company} also provides comprehensive technical support and after-sales service to its customers. The company's team of experts works closely with customers to understand their filtration needs and provide customized solutions to meet their requirements.With a commitment to quality and customer satisfaction, {Company} has established itself as a trusted partner for industries seeking reliable filtration solutions. The company's plate and frame filter presses have been widely adopted by customers around the world, earning a reputation for their performance and durability.In conclusion, plate and frame filter presses play a vital role in various industries, offering efficient and cost-effective solutions for solid-liquid separation. {Company} continues to be a leading supplier of filter presses, providing high-quality equipment and superior support to its customers. As industries continue to prioritize efficiency and sustainability, the demand for reliable filtration solutions is expected to grow, further solidifying the importance of plate and frame filter presses in the industrial landscape.

Versatile Metal Conveyor Belts for Diverse Applications

and Product Range.Metal Conveyor Belts: The Ultimate Solution for Every ApplicationConveyor belts are an essential component of industrial processes. They play a critical role in the transportation of materials, products, and goods across various stages of production and distribution. While there are different types of conveyor belts available in the market, metal conveyor belts are one of the most popular choices. They offer numerous advantages, such as strength, durability, and versatility, making them the ultimate solution for every application.At (need to remove brand name), we offer a wide range of metal conveyor belts that cater to various industries and applications. Our product range includes stainless steel belts, wire mesh belts, flat wire belts, chain belts, and modular belts, among others. Each of these belts features unique characteristics that make them suitable for specific purposes. Let's delve into each of them and see how they can benefit your business.Stainless Steel BeltsStainless steel belts are the most widely used metal belts in food, chemical, and pharmaceutical industries. They are highly resistant to corrosion, heat, and wear, making them ideal for conveying materials that require strict hygienic standards and harsh operating conditions. Stainless steel belts come in different grades, such as 304, 316, and 316L, to suit different environments and applications.Wire Mesh BeltsWire mesh belts consist of interlocked chains and metal wires that form a flat surface. They provide excellent airflow and drainage, making them perfect for applications such as drying, cooling, and heat treatment. Wire mesh belts are also highly durable, withstanding extreme temperatures and heavy loads.Flat Wire BeltsFlat wire belts are similar to wire mesh belts but consist of flat wires instead of interlocked chains. They offer smoother carrying surfaces, making them suitable for conveying delicate materials such as electronics and textiles. Flat wire belts also provide excellent heat and corrosion resistance, making them ideal for high-temperature and harsh environments.Chain BeltsChain belts are comprised of metal links that form a continuous loop. They are ideal for heavy-duty applications that require high strength and load-carrying capacity, such as mining, construction, and automotive industries. Chain belts can also withstand extreme temperatures, making them ideal for extreme heat or cold conditions.Modular BeltsModular belts are made of plastic or metal modules that interlock to form a continuous surface. They are ideal for applications that require precision, such as packaging, and can handle both light and heavy materials. Modular belts also come in different colors, making them suitable for color-coded sorting and identification.Overall, metal conveyor belts offer numerous benefits and are suitable for various applications. At (need to remove brand name), we provide a wide range of metal conveyor belts to cater to different industries and applications. Our belts are highly durable, reliable, and customizable to fit your exact needs. Contact us today to learn more about our products and how we can help improve your industrial processes.

Durable PVC Gate Valve for Long-lasting Performance

PVC Gate Valve Market Booming with Latest Innovation | Company IntroductionThe global PVC gate valve market is witnessing a surge in demand with the latest technological innovations and advancements. With the growing need for efficient flow control mechanisms in various industries, the PVC gate valve has emerged as a reliable and cost-effective solution.The PVC gate valve is a type of valve used to control the flow of liquids and gases in a piping system. It is designed with a gate, which is raised and lowered to regulate the flow, making it an ideal choice for applications where a tight shut-off is required.One company that has made a significant impact on the PVC gate valve market is {}. With over 20 years of experience in the manufacturing and distribution of industrial valves, {} has established itself as a trusted name in the industry. The company is renowned for its commitment to quality, innovation, and customer satisfaction.{} offers a wide range of PVC gate valves that are designed to meet the specific needs of different industries, including water treatment, chemical processing, irrigation, and more. The company's products are known for their durability, reliability, and high performance, making them a preferred choice among customers worldwide.One of the key factors driving the demand for PVC gate valves is the increasing focus on water and wastewater management. With the rising concerns about water scarcity and environmental sustainability, there is a growing need for efficient and reliable valves that can help in the conservation and efficient distribution of water. PVC gate valves are well-suited for such applications, as they are resistant to corrosion and can withstand harsh environmental conditions.Another factor contributing to the growth of the PVC gate valve market is the rapid expansion of the chemical and petrochemical industry. As the demand for chemical products continues to rise, there is a greater need for valves that can handle the demanding requirements of chemical processing. PVC gate valves are well-suited for these applications, as they offer excellent chemical resistance and can handle a wide range of corrosive substances.In addition to industrial applications, PVC gate valves are also being increasingly used in residential and commercial plumbing systems. The growing construction activities and infrastructure development projects worldwide have led to a surge in the demand for high-quality valves that can ensure efficient water flow and distribution.With the increasing adoption of PVC gate valves across various industries, manufacturers like {} are continuously working on improving their products and introducing innovative solutions to meet the evolving needs of their customers. The company's dedication to research and development has enabled it to offer a range of advanced PVC gate valves that are equipped with the latest features and technologies.In conclusion, the PVC gate valve market is experiencing a period of rapid growth, driven by the increasing demand for efficient flow control solutions in various industries. With companies like {} leading the way with their innovative products and unwavering commitment to quality, the future looks promising for the PVC gate valve market. As the industry continues to evolve, it is expected that PVC gate valves will play an even more significant role in ensuring the smooth and efficient operation of piping systems across the globe.

High-Quality Rectangular Pipe: The Latest News and Updates

Rectangular Pipe Manufacturer Unveils Revolutionary New Product[Company Name], a leading manufacturer of steel products, has recently announced the release of a groundbreaking new product: the Rectangular Pipe. The company has made a name for itself in the steel industry with its high-quality products and innovative solutions, and the Rectangular Pipe is no exception.The Rectangular Pipe is poised to revolutionize the way that steel pipes are used in construction and manufacturing. Its unique design and exceptional durability make it a standout choice for a wide range of applications, from building support structures to industrial piping systems.Designed with precision engineering and manufactured using the latest technology, the Rectangular Pipe boasts exceptional strength and corrosion resistance. This makes it ideal for use in environments where traditional round pipes may not be as effective or efficient. Its rectangular shape also offers enhanced load-bearing capabilities, making it a versatile and reliable choice for a variety of projects.[Company Name] has a long-standing reputation for delivering top-notch steel products, and the Rectangular Pipe is no exception. The company has invested heavily in research and development to ensure that this new product meets the highest standards of quality and performance. Its dedication to excellence is evident in the exceptional craftsmanship and attention to detail that are hallmarks of the Rectangular Pipe.In addition to its superior construction and durability, the Rectangular Pipe is also environmentally friendly. Made from recycled steel and manufactured using sustainable practices, it aligns with the company's commitment to reducing its carbon footprint and promoting a greener future for the industry.The launch of the Rectangular Pipe comes at a time of rapid growth and expansion for [Company Name]. With a strong focus on continuous improvement and innovation, the company has positioned itself as a leader in the steel industry. Its commitment to delivering cutting-edge products that meet the evolving needs of its customers has set it apart from the competition.In a statement regarding the release of the Rectangular Pipe, [Company Name] CEO expressed great enthusiasm for the product's potential impact on the industry. "We are thrilled to introduce the Rectangular Pipe to the market," he said. "This is a game-changer for us and for our customers. It represents the culmination of years of hard work and dedication to pushing the boundaries of what is possible in steel manufacturing. We believe that the Rectangular Pipe will set a new standard for excellence in our industry."The Rectangular Pipe is now available for purchase through [Company Name]'s extensive network of distributors and partners. Its arrival has been met with great anticipation and excitement from customers and industry professionals alike, who recognize its potential to revolutionize the way that steel pipes are used in a wide range of applications.As the industry continues to evolve and grow, [Company Name] is committed to remaining at the forefront of innovation and excellence. The release of the Rectangular Pipe is a testament to the company's ongoing dedication to pushing the boundaries of what is possible in steel manufacturing, and its commitment to providing its customers with the most advanced and reliable products on the market. With the introduction of the Rectangular Pipe, [Company Name] is poised to further solidify its standing as a leader in the steel industry.

Durable High Pressure Rubber Hose for Various Applications

High Pressure Rubber Hose, a leading manufacturer of industrial hoses and rubber products, has recently introduced a new line of high pressure rubber hoses designed for various applications in the industrial and commercial sectors. With over 20 years of experience in the industry, High Pressure Rubber Hose has built a strong reputation for providing high-quality products and excellent customer service.The new line of high pressure rubber hoses is designed to meet the growing demand for durable and reliable hoses that can withstand high pressure and extreme conditions. These hoses are manufactured using the latest technology and high-quality materials to ensure superior performance and long-lasting durability. Whether it's for hydraulic systems, oil and gas drilling, mining, construction, or industrial machinery, High Pressure Rubber Hose offers a wide range of hose solutions to meet the diverse needs of its customers.One of the key features of the new line of high pressure rubber hoses is their ability to handle a wide range of temperatures and pressures, making them suitable for use in a variety of challenging environments. These hoses are also designed to withstand abrasion, corrosion, and other types of wear and tear, ensuring that they can withstand the rigors of industrial and commercial applications. In addition, they are flexible and easy to install, making them ideal for use in tight spaces and complex systems.High Pressure Rubber Hose is committed to providing its customers with the highest quality products and exceptional service. The company employs a team of skilled engineers and technicians who work tirelessly to ensure that each hose meets the highest standards of quality and performance. In addition, High Pressure Rubber Hose is dedicated to continuous research and development to stay at the forefront of innovation in the industry.In addition to its new line of high pressure rubber hoses, the company also offers custom hose solutions to meet the specific needs of its customers. Whether it's a unique hose design, a special material requirement, or a specific performance specification, High Pressure Rubber Hose can work closely with its customers to develop tailored solutions that meet their exact requirements. This commitment to customization sets High Pressure Rubber Hose apart from its competitors and makes it a trusted partner for companies seeking reliable hose solutions.High Pressure Rubber Hose is also dedicated to environmental sustainability and responsible manufacturing practices. The company adheres to strict quality control measures and environmental standards to ensure that its products are safe for the environment and its workers. Additionally, High Pressure Rubber Hose is committed to reducing its carbon footprint and minimizing waste in its manufacturing processes.With its new line of high pressure rubber hoses and its commitment to quality, innovation, and sustainability, High Pressure Rubber Hose is well-positioned to meet the evolving needs of the industrial and commercial sectors. The company's dedication to superior products and customer satisfaction makes it a trusted and reliable partner for companies seeking high-quality hose solutions.In conclusion, the introduction of the new line of high pressure rubber hoses further solidifies High Pressure Rubber Hose's position as a leader in the industry. With its dedication to quality, innovation, custom solutions, and environmental responsibility, the company continues to set the standard for excellence in industrial hose manufacturing. As the demand for durable and reliable hose solutions continues to grow, High Pressure Rubber Hose is poised to meet the needs of its customers with superior products and exceptional service.

Different Types of Conveyor Idlers: A Complete Guide

For over 30 years, {} has been a leading manufacturer of conveyor idlers, providing innovative solutions for various industries around the world. With a strong commitment to quality and customer satisfaction, {} has established itself as a trusted partner for companies seeking reliable and efficient conveyor systems. The company's extensive range of conveyor idlers has been designed to meet the diverse needs of its customers, offering a wide variety of options to suit different applications.Conveyor idlers are an essential component of belt conveyors, playing a crucial role in supporting the conveyor belt and carrying the load. {} offers a range of different types of conveyor idlers, each with its own unique features and benefits. These idlers are designed to effectively handle different types of materials, ensuring smooth and efficient operation of the conveyor system.One of the most commonly used types of conveyor idlers is the flat belt idler. This type of idler is designed to support the conveyor belt and provide a smooth surface for the belt to slide on. Flat belt idlers are often used in applications where the conveyor belt needs to travel long distances at high speeds, such as in mining and quarrying operations. {}'s flat belt idlers are engineered to withstand heavy loads and harsh operating conditions, ensuring reliable performance in demanding environments.Another type of conveyor idler offered by {} is the troughing idler, which is designed to support the conveyor belt in a trough shape to prevent spillage of materials. Troughing idlers are commonly used in applications where the conveyor belt carries bulk materials, such as in the construction and agricultural industries. {}'s troughing idlers are built to withstand the impact of heavy materials and provide a stable surface for the conveyor belt, reducing the risk of spillage and damage to the belt.In addition to flat belt and troughing idlers, {} also offers impact idlers, which are designed to absorb the impact of materials being loaded onto the conveyor belt. Impact idlers are essential for protecting the conveyor belt and ensuring smooth material handling, particularly in industries such as shipping and logistics, where materials are loaded onto conveyor belts at high speeds. {}'s impact idlers are designed to minimize the force of impact on the conveyor belt, prolonging its lifespan and reducing maintenance costs.Along with these standard types of conveyor idlers, {} also provides training idlers, which are used to align the conveyor belt and prevent it from running off its track. Training idlers are crucial for maintaining the stability and efficiency of the conveyor system, particularly in applications where the belt is required to travel along a specific path, such as in the manufacturing and distribution industries.With a long-standing reputation for excellence and a commitment to innovation, {} continues to be a leading provider of conveyor idlers for a wide range of industries. The company's dedication to quality and customer satisfaction has earned it a loyal customer base, and its comprehensive range of conveyor idlers has been designed to meet the diverse needs of its clients. Whether it's flat belt idlers, troughing idlers, impact idlers, or training idlers, {} has the expertise and experience to provide efficient and reliable solutions for any conveyor system.

Timers: A Comprehensive Guide Electric solenoid valve timers are essential components in the automation of fluid and gas control in various industries. These timers come in different designs and functionalities to suit various applications and requirements. In this blog, we will guide you through an in-depth understanding of solenoid valve timers and their applications. What are Solenoid Valve Timers? A solenoid valve timer is an electrical device that controls the opening and closing of solenoid valves according to pre-set time intervals. The timer regulates the process flow by providing an electrical signal that triggers the solenoid valve to open, close, or partially open at precise times. They are also used to prevent system overflows, limit liquid levels, and to sequence the operation of pumps and compressors. How Do Solenoid Valve Timers Work? Solenoid valve timers operate by using an electronic timer circuit and a solenoid valve that controls the flow of fluid or gas through the valve body. The timer is pre-set to control the duration of the valve's open state. The timer circuit sends a signal to the solenoid valve, causing it to open or close. The solenoid valve is an electromechanical device that converts electrical energy into mechanical action. Applications of Solenoid Valve Timers Solenoid valve timers are used in many industries and applications, such as: 1. Irrigation Systems Solenoid valve timers are used in irrigation systems to automate the watering process. The timer controls the water flow through the solenoid valve, ensuring that plants or crops receive consistent and regulated amounts of water. 2. Industrial Automation Solenoid valve timers are used in industrial automation systems to control the flow of fluids and gases through different processes. They are also used in storage tanks, boilers, and pumps to regulate their operation. 3. HVAC Systems Heating, Ventilation, and Air Conditioning (HVAC) systems utilize solenoid valve timers to control the flow of refrigerants, coolants, and airflow. The timer regulates the timing of the cycles of the components to ensure that the system operates efficiently. 4. Medical Equipment Solenoid valve timers are used in medical equipment and laboratory applications to control the flow of fluids and gases accurately. They are commonly used in hospital laundry systems and automated laboratory equipment. Factors to Consider When Choosing a Solenoid Valve Timer When selecting a solenoid valve timer, you must consider the following factors: 1. Timer Type Solenoid valve timers come in different types, including on-delay, off-delay, pulse, and interval timer types. Each type has its unique function and duration, depending on the application requirements. 2. Timing Range The timing range is the number of seconds, minutes, or hours that the solenoid valve remains open or closed. Consider the timing range of the timer according to the application. 3. Power Requirements The timer power requirements should match those of the solenoid valve or the equipment the timer is controlling. Select a timer that operates on the required voltage and frequency. 4. Interface and Mounting Ensure that the timer has an interface and mounting design that suits the device or system it will control. Conclusion Solenoid valve timers are essential in the automation of fluid and gas control processes in various industries. Understanding their functions and applications is crucial in selecting the right type of timer for your system. Remember to consider the timing range, power requirements, interface, and mounting design when selecting a solenoid valve timer for your application. In summary, electric solenoid valve timers are critical in the control and regulation of fluid and gas flow in many applications. Tameson offers a wide range of solenoid valve timers suitable for various industries. Browse our website or contact us for more information.

High-quality Trunnion Mounted Ball Valve for Reliable Flow Control

Reliavalve Trunnion Mounted Ball Valve: The Future of Flow ControlFlow control systems are essential to the safe and efficient operation of a wide range of industries, including oil and gas, chemical processing, and power generation. As such, the reliability and performance of flow control valves are crucial to the success of these industries. Recognizing this need, Reliavalve has designed and manufactured the Trunnion Mounted Ball Valve to deliver unmatched performance and reliability in these demanding environments.The Trunnion Mounted Ball Valve leverages cutting-edge engineering and advanced manufacturing techniques to offer end-users unparalleled flow control capabilities. One of the key features of this innovative valve is its bubble tight seal, which blocks the flow from upstream and downstream. This ensures that the valve is fully closed, preventing any unintended leakage or contamination that could negatively impact safety or production efficiency. Due to its high-performance capabilities, the Trunnion Mounted Ball Valve is designed to meet the strict standards set by API 6D and Gost.The Trunnion Mounted Ball Valve is also designed to be highly durable, able to withstand the challenging environments presented by a wide range of industries. This durability is achieved through the use of advanced materials and manufacturing techniques. The valve body is constructed from high-quality steel, which is highly resistant to corrosion, wear, and chemical damage. The ball and stem are also manufactured using the latest techniques to ensure that they can operate under high-pressure or high-temperature conditions without any problems.The Trunnion Mounted Ball Valve is also incredibly versatile, designed to be used in a diverse range of applications. Whether users need to control the flow of crude oil, natural gas, or corrosive chemicals, the valve delivers consistent and reliable performance. Its configuration can be customized to match the specific requirements of different industries, ensuring optimal flow control operations.Safety is another key feature of Reliavalve's Trunnion Mounted Ball Valve. Safety has been integrated into the design of the valve, and it has undergone rigorous testing to ensure that it can operate correctly under the most stringent conditions. Reliavalve has worked closely with various industries to develop procedures, guidelines, and training programs that ensure the safe operation of the valve, reducing the risks associated with flow control systems.In conclusion, Reliavalve's Trunnion Mounted Ball Valve is a game-changer that delivers the highest levels of performance, durability, versatility, and safety. This cutting-edge valve is a result of Reliavalve's constant commitment to innovation and engineering excellence. The company's mission is to provide reliable and innovative solutions that help industries optimize their operations, increase productivity, and improve safety. With the Trunnion Mounted Ball Valve, Reliavalve is revolutionizing the flow control industry, providing a solution that is set to shape the future of industries worldwide.