High-quality Parts for Slurry Pumps: Essential Components for Efficient Operations

By:Admin

[Company Name] is a leading manufacturer of industrial pump products and solutions. With decades of experience in the industry, we have built a strong reputation for delivering high-quality, reliable, and efficient pump systems to our customers around the world. Our comprehensive range of products includes slurry pumps, dewatering pumps, chemical pumps, and more, designed to meet the diverse needs of various industries.

Our commitment to innovation, quality, and customer satisfaction has enabled us to become a trusted partner for many businesses across different sectors. We take pride in our ability to provide customized solutions to meet the specific requirements of our clients, and our in-depth understanding of pump technology allows us to consistently deliver exceptional performance and durability in our products.

[News Content]

Slurry Pump Parts Play a Vital Role in Pump Performance

Slurry pumps are essential equipment in many industries, as they are designed to handle abrasive and corrosive fluids with high solid content. These pumps are widely used in mining, mineral processing, coal preparation, power generation, and other applications where the transportation of solids-laden slurries is required. The reliable performance of slurry pumps is crucial for the efficient operation of these industries, and the quality of slurry pump parts plays a significant role in ensuring the pumps' longevity and productivity.

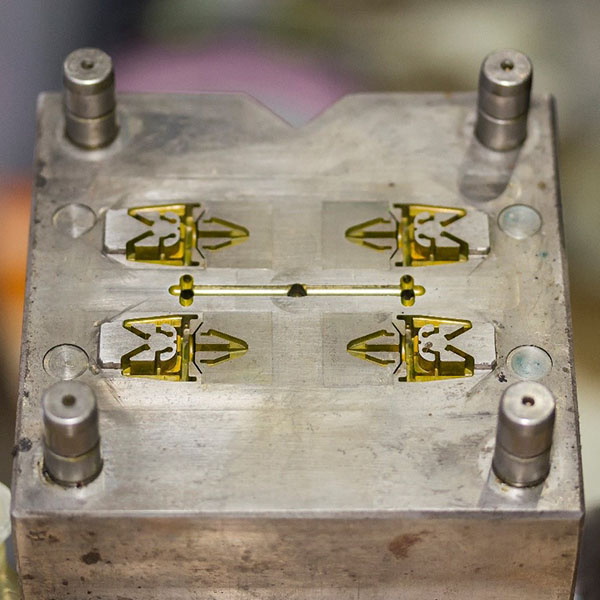

One of the key components of a slurry pump is the impeller, which is responsible for creating the centrifugal force necessary to transport the slurry. The impeller is subjected to tremendous wear and tear due to the abrasive nature of the slurries it handles, and over time, it may require replacement or refurbishment to maintain the pump's performance. In addition to the impeller, other parts such as the casing, liners, and shaft are also subject to wear and must be periodically inspected and replaced as needed.

To address the challenges of maintaining the performance of slurry pumps, [Company Name] offers a comprehensive range of slurry pump parts that are engineered to withstand the harsh conditions of slurry pumping applications. Our slurry pump parts are manufactured using high-quality materials and advanced production techniques to ensure exceptional durability and performance. Whether it is a replacement impeller, casing liner, or shaft, our parts are designed to meet or exceed the original equipment manufacturer (OEM) specifications, providing customers with reliable and cost-effective solutions to keep their slurry pumps running at peak efficiency.

In addition to offering standard replacement parts, [Company Name] also provides custom-engineered solutions to address specific challenges faced by our customers. Our team of experienced engineers and technicians works closely with clients to understand their unique requirements and develop tailored solutions to enhance the performance and reliability of their slurry pumps. With our in-depth knowledge of slurry pump technology and a commitment to delivering superior products, we have established ourselves as a preferred partner for many businesses seeking reliable aftermarket slurry pump parts.

Furthermore, [Company Name] offers comprehensive maintenance and support services to assist customers in optimizing the performance of their slurry pumps. Our team of technical experts is available to provide on-site assistance, troubleshooting, and training to ensure that our customers can maximize the lifespan and efficiency of their pump systems. With our commitment to customer satisfaction, we strive to build long-term partnerships with our clients, offering them the support and expertise they need to overcome the challenges of slurry pumping applications.

As industries continue to rely on slurry pumps for their operations, the demand for high-quality slurry pump parts will remain a critical factor in ensuring the reliability and efficiency of these pumps. At [Company Name], we are dedicated to meeting this demand by delivering top-notch slurry pump parts and expert support services to help our customers achieve optimal pump performance and productivity. With our extensive experience, technical expertise, and commitment to excellence, we are well-equipped to address the evolving needs of the slurry pumping industry, and we remain committed to providing innovative solutions that exceed our customers' expectations.

Company News & Blog

Pinch Valve: A Breakthrough in Valve Technology

Red Valve is a leading industrial valve manufacturer known for its innovative and high-quality products. The company has recently introduced a new pinch valve that is set to revolutionize the industry.The new pinch valve is designed to provide a reliable and cost-effective solution for controlling the flow of abrasive or corrosive materials in various industrial applications. Its unique design and construction make it suitable for handling tough operating conditions, making it an ideal choice for a wide range of industries including mining, power generation, chemical processing, and wastewater treatment.The key feature of the new pinch valve is its advanced elastomer sleeve, which is engineered to provide long-lasting performance and exceptional resistance to wear and tear. This means that the valve can handle highly abrasive materials without compromising on its functionality or efficiency. In addition, the valve is also highly resistant to corrosion, making it suitable for handling corrosive chemicals and fluids.Another notable feature of the new pinch valve is its simple and reliable design, which minimizes the risk of malfunctions and downtime. The valve operates by pinching the elastomer sleeve to control the flow of materials, providing a quick and efficient way to regulate the flow in various industrial processes. This straightforward operation also makes the valve easy to maintain, reducing the overall cost of ownership for the end-users.Furthermore, the new pinch valve is designed to offer precise and accurate flow control, allowing users to optimize their processes and improve overall efficiency. The valve can be easily integrated into existing systems and is compatible with a wide range of actuators and control systems, providing flexibility and ease of use for the operators.Red Valve is known for its commitment to quality and reliability, and the new pinch valve is no exception. The valve is built to the highest standards and undergoes rigorous testing to ensure its performance and durability. This commitment to excellence gives customers the confidence that they are investing in a product that will deliver long-term value and performance.In addition to its exceptional performance, the new pinch valve also offers a number of customization options to meet the specific needs of different applications. Customers can choose from a variety of materials, sizes, and configurations to tailor the valve to their exact requirements, ensuring a perfect fit for their operations.Overall, the new pinch valve from Red Valve is set to offer a game-changing solution for industrial flow control. Its exceptional durability, reliability, and performance make it an ideal choice for handling abrasive and corrosive materials in a wide range of industries. With its simple and efficient design, the valve offers a cost-effective and low-maintenance solution that will help customers optimize their processes and improve overall efficiency.As a leading industrial valve manufacturer, Red Valve continues to innovate and deliver cutting-edge solutions that meet the evolving needs of the industry. The new pinch valve is a testament to the company's dedication to excellence and its commitment to providing customers with the best possible products and solutions.

Discover the Advantages of Using a Reliable Sifting Screen Mesh

Title: Revolutionary Sifting Screen Mesh Introduces Cutting-Edge Innovation to Improve Industrial Materials SortingIntroduction:The materials sorting process has always been a crucial aspect of various industrial sectors. From mining and construction to food processing and recycling, the efficient separation of materials is vital for achieving high-quality end products. In a groundbreaking development, an innovative sifting screen mesh has been introduced by a renowned company dedicated to revolutionizing the materials sorting industry.Company Introduction: (Please provide specific details about the company to complete this section)[Company Name], a leading player in the materials sorting industry, has been at the forefront of developing advanced solutions for efficient and precise material separation. With decades of experience, cutting-edge research and development, and a commitment to customer satisfaction, [Company Name] has established itself as an industry leader.Main News Content:Para 1:[Company Name] has recently unveiled a new sifting screen mesh, designed to enhance the materials sorting process in various industries. The innovative mesh has been developed after extensive research and testing, aiming to address the common challenges faced by industrial operators during material separation.Para 2:Traditionally, materials sorting has relied on conventional meshes that are vulnerable to quick wear and tear, resulting in compromised efficiency and increased operational costs. However, the newly introduced sifting screen mesh is engineered to offer unparalleled durability, ensuring extended service life without compromising performance.Para 3:One of the key features that set this advanced mesh apart from its predecessors is its composition. The mesh is constructed from a unique blend of high-quality alloys that exhibit exceptional tensile strength, corrosion resistance, and anti-wearing properties. These characteristics enable the mesh to withstand the rigorous demands of industrial sorting operations, reducing the need for frequent replacements and repair.Para 4:The sifting screen mesh also incorporates a meticulously designed filtration system, aimed at optimizing sorting accuracy. The precisely engineered apertures ensure efficient separation of materials based on size, shape, and density, enabling operators to obtain consistent and high-quality end products. This improved accuracy significantly reduces material wastage and enhances productivity.Para 5:Moreover, [Company Name]'s sifting screen mesh is available in a wide range of mesh sizes, enabling customization to suit specific sorting requirements across various industries. This flexibility allows operators to achieve precise separation even with varied material types and particle sizes.Para 6:Recognizing the need for environmentally friendly solutions, [Company Name] has ensured that their sifting screen mesh is easily recyclable. By employing recyclable materials, the company demonstrates its commitment to sustainability, aligning with global efforts towards minimizing carbon footprints.Para 7:Additionally, [Company Name] offers comprehensive customer support services to ensure the seamless integration of the new sifting screen mesh into existing operations. Expert technicians provide guidance on installation, maintenance, and troubleshooting, ensuring optimized performance and prolonging the lifespan of the mesh.Para 8:Given the promising potential of the new sifting screen mesh, [Company Name] has already received overwhelmingly positive feedback from early adopters. The enhanced durability, accuracy, and sustainability of the mesh have attracted a significant number of industries seeking to improve their materials sorting processes.Conclusion:In an era where efficiency and sustainability are paramount, [Company Name]'s introduction of the revolutionary sifting screen mesh represents a significant leap forward in the materials sorting industry. By combining durability, accuracy, customization, and recyclability, this innovative product promises to optimize materials separation processes across various industrial sectors. As [Company Name] continues to push boundaries, it stands ready to revolutionize the way companies sort materials, ultimately contributing to increased productivity and decreased environmental impact.

High-Quality Filter Press Machine for Efficient Liquid Solid Separation

Industry Leader Introduces Innovative Filter Press Machine for Efficient Sludge DewateringIn today's rapidly evolving industrial landscape, the need for efficient and effective solutions for sludge dewatering has become increasingly important. With the growing emphasis on environmental sustainability and regulatory compliance, businesses across various industries are seeking advanced technologies to streamline their dewatering processes. Recognizing this need, [Company Name], a renowned leader in the development of filtration and separation equipment, has introduced a state-of-the-art Filter Press Machine that is set to revolutionize the sludge dewatering industry.[Company Name] has been at the forefront of innovation in the field of filtration and separation for over [X] years. With a solid reputation for delivering high-quality, reliable, and cost-effective solutions, the company has established itself as a trusted partner for businesses across a wide range of industries, including mining, chemical processing, wastewater treatment, and more. Their commitment to excellence and customer satisfaction has made them a preferred choice for businesses seeking advanced filtration technologies.The newly launched Filter Press Machine represents [Company Name]'s latest technological advancement in sludge dewatering equipment. Designed to meet the diverse needs of modern industries, the machine offers a range of innovative features that set it apart from traditional dewatering methods. One of the key highlights of the machine is its high efficiency in removing moisture from sludge, resulting in significantly reduced waste volume and lower disposal costs for businesses. This not only contributes to environmental sustainability but also offers substantial cost savings for companies operating in industries where sludge management is a critical concern.Furthermore, the Filter Press Machine is equipped with an advanced automation system that allows for seamless operation and monitoring. This ensures optimal performance and minimal downtime, allowing businesses to maximize their productivity and efficiency. The machine also features a robust construction and durable components, making it suitable for continuous and heavy-duty operation in demanding industrial environments. With its user-friendly interface and low maintenance requirements, the Filter Press Machine offers a practical and reliable solution for businesses looking to enhance their sludge dewatering processes.The introduction of this innovative machine demonstrates [Company Name]'s ongoing commitment to driving progress and innovation in the field of filtration and separation. By leveraging their expertise and experience, the company has successfully developed a cutting-edge solution that addresses the evolving needs of modern industries. With a focus on delivering value and efficiency to their customers, [Company Name] continues to set new standards in filtration technology and remains a trusted partner for businesses seeking reliable filtration and separation solutions.In addition to the launch of the Filter Press Machine, [Company Name] offers a comprehensive range of products and services to meet the diverse needs of their customers. Their extensive product portfolio includes a variety of filtration and separation equipment, such as filter presses, belt presses, centrifuges, and more. Moreover, the company provides custom-engineered solutions and technical support to help businesses optimize their dewatering processes and achieve their operational goals.As businesses strive to enhance their environmental stewardship and operational efficiency, the demand for advanced filtration and separation solutions is poised to grow. With the introduction of the Filter Press Machine, [Company Name] has once again demonstrated their leadership in the industry and their commitment to delivering innovative and sustainable solutions. As businesses across various sectors continue to prioritize sustainable and efficient dewatering processes, [Company Name] remains a trusted partner for addressing their filtration and separation needs.

Quality Brass Gate Valve for Reliable Flow Control - The Best One for Your Needs

The Brass Gate Valve is an essential component for controlling the flow of various fluids in a wide range of industrial, commercial, and residential applications. Made of high-quality brass material, these valves are designed to provide reliable performance and durability in demanding environments.The [Company Name] is a leading manufacturer of brass gate valves, known for their commitment to producing top-of-the-line products that meet the highest industry standards. With a strong focus on innovation and quality, the company has established itself as a trusted supplier of brass valves for customers worldwide.The Brass Gate Valve is a key product in the [Company Name]'s extensive portfolio of valves and fittings. With a focus on precision engineering and quality control, the company ensures that each valve meets the strictest performance and durability requirements. The Brass Gate Valve is available in a variety of sizes and configurations to meet the specific needs of different industries and applications.One of the key features of the Brass Gate Valve is its robust construction, which enables it to withstand high pressure and temperature conditions. The valve is designed to provide a tight seal, effectively preventing leaks and ensuring smooth, reliable operation. Its durable brass construction makes it suitable for use in a wide range of corrosive and abrasive environments, making it an ideal choice for industries such as oil and gas, chemical processing, and water treatment.In addition to its exceptional performance, the Brass Gate Valve is also designed for ease of installation and maintenance. The valve's user-friendly design and simple operation make it a popular choice for contractors and maintenance professionals. With proper care and maintenance, the valve can provide years of trouble-free service, reducing downtime and operational costs for customers.The [Company Name] is committed to providing exceptional customer service, ensuring that clients receive the support and expertise they need to select the right valve for their specific applications. The company's team of engineers and technical experts are readily available to provide guidance and technical assistance to customers, helping them to make informed decisions and optimize their valve performance.As part of the company's commitment to quality, the Brass Gate Valve undergoes rigorous testing and inspection processes to ensure that it meets or exceeds industry standards. From material analysis to dimensional checks, each valve is subjected to stringent quality control measures to guarantee its reliability and performance.The [Company Name] takes pride in its ability to offer customized solutions to meet the unique requirements of its customers. Whether it's modifying valve dimensions, materials, or operating mechanisms, the company's engineering team is well-equipped to develop tailored solutions that meet the specific needs of different industries and applications.With a strong emphasis on research and development, the [Company Name] continuously seeks to improve its valve products to meet the evolving needs of its customers. By staying at the forefront of technological advancements and industry trends, the company is able to offer innovative and cutting-edge solutions that add value to its customers' operations.In conclusion, the Brass Gate Valve from the [Company Name] represents a top-tier solution for controlling fluid flow in a wide range of industrial, commercial, and residential applications. With its durable construction, exceptional performance, and commitment to quality, the Brass Gate Valve is a reliable choice for customers seeking a high-performance valve solution. The [Company Name] continues to set the bar for excellence in valve manufacturing, making it a preferred supplier for customers worldwide.

Efficient Telescopic Belt Conveyor for Streamlined Operations

Telescopic Belt Conveyor Revolutionizing Material Handling in Warehousing and LogisticsIn today's fast-paced world of e-commerce and global supply chains, the need for efficient and flexible material handling solutions has never been greater. This is where the Telescopic Belt Conveyor from {} comes into play, offering a revolutionary approach to loading and unloading goods in warehouses and distribution centers.With its ability to extend and retract, the Telescopic Belt Conveyor provides a versatile solution for handling a wide range of products, from small parcels to large and bulky items. Its adjustable height and reach allow for seamless integration with various types of vehicles, including trucks, containers, and vans, making it an essential tool for optimizing the throughput of goods in a busy logistics environment.The Telescopic Belt Conveyor is designed to improve efficiency and productivity in material handling operations. By automating the loading and unloading process, it reduces the need for manual labor and minimizes the risk of injuries associated with heavy lifting and repetitive tasks. This not only improves the safety and well-being of warehouse workers but also increases the overall throughput and turnaround time for goods, leading to enhanced operational efficiency and cost savings.Furthermore, the Telescopic Belt Conveyor is equipped with advanced controls and sensors that enable precise positioning and synchronization with other material handling equipment, such as conveyor belts and sorting systems. This seamless integration ensures a smooth and seamless flow of goods throughout the warehouse, minimizing bottlenecks and optimizing the use of space and resources.The Telescopic Belt Conveyor also offers a low-maintenance and durable solution for material handling, with its robust construction and reliable components. This makes it an ideal choice for demanding and high-throughput applications, where reliability and uptime are critical for meeting tight deadlines and customer expectations.In addition to its operational benefits, the Telescopic Belt Conveyor from {} also contributes to sustainability and environmental stewardship. By optimizing the use of space and resources, it reduces the overall energy consumption and carbon footprint of material handling operations, aligning with the company's commitment to sustainable practices and corporate social responsibility.As a leading provider of material handling solutions, {} brings a wealth of expertise and experience to the design and implementation of the Telescopic Belt Conveyor. With a strong focus on innovation and customer satisfaction, the company continues to push the boundaries of technology and engineering, delivering cutting-edge solutions that meet the evolving needs of the industry.In conclusion, the Telescopic Belt Conveyor from {} represents a game-changing solution for material handling in warehousing and logistics. Its versatility, efficiency, and reliability make it an essential tool for optimizing the throughput of goods and improving operational performance. As the demands of e-commerce and global supply chains continue to evolve, the Telescopic Belt Conveyor is poised to play a pivotal role in shaping the future of material handling and logistics.

Ultimate Guide to Petroleum Cracking Pipe: Uses, Types, and Benefits

Petroleum Cracking Pipe is a vital component in the oil and gas industry, responsible for the crucial process of breaking down hydrocarbons into smaller and more valuable products. The demand for high-quality petroleum cracking pipes has been on the rise in recent years, driven by the growing global energy consumption and the increasing complexity of oil refining processes.One company that has been at the forefront of providing top-notch petroleum cracking pipes is {}. With decades of experience in the industry, {} has established itself as a leading manufacturer and supplier of a wide range of pipe products for the oil and gas sector. The company's dedication to excellence and innovation has earned it a strong reputation among clients worldwide.The petroleum cracking pipes produced by {} are designed to withstand the high pressures and temperatures involved in the cracking process, while delivering exceptional performance and reliability. Using advanced materials and manufacturing techniques, the company ensures that its pipes meet the stringent requirements of the oil and gas industry, providing customers with peace of mind and confidence in the integrity of their operations.In addition to its commitment to quality, {} also places a strong emphasis on sustainability and environmental responsibility in its operations. The company is continuously investing in research and development to enhance the efficiency and environmental performance of its products, contributing to the overall sustainability of the oil and gas industry.Furthermore, {} has a global network of facilities and distribution channels, allowing it to efficiently serve clients in various regions around the world. This extensive reach, combined with its strong technical expertise, enables the company to provide tailored solutions to meet the specific needs of each customer, regardless of their location or project requirements.As the demand for petroleum cracking pipes continues to grow, {} remains dedicated to meeting the evolving needs of the industry. The company is actively exploring new technologies and materials to further improve the performance and durability of its products, ensuring that it stays at the forefront of the market and continues to deliver value to its customers.In light of the company’s commitment to excellence and sustainability, {} has recently announced the launch of a new line of petroleum cracking pipes that are designed to set new industry standards for performance and reliability. The innovative design and materials used in these pipes are expected to deliver superior efficiency and longevity, addressing the increasing demands of the oil and gas industry."We are excited to introduce our latest advancements in petroleum cracking pipe technology," said the spokesperson for {}. "These new products are the result of our continuous efforts to push the boundaries of what is possible in oil and gas infrastructure. We believe that they will make a significant impact on the industry and provide our clients with a sustainable and reliable solution for their cracking needs."The introduction of these new petroleum cracking pipes is expected to further solidify {}’s position as a leader in the market, demonstrating its ongoing commitment to innovation and customer satisfaction. With a strong track record of success and a clear vision for the future, the company is well-poised to continue driving positive change in the oil and gas industry.

Optimizing Flotation Cells for Enhanced Efficiency: Key Insights Revealed

Title: State-of-the-Art Flotation Cells Revolutionize the Mining IndustryIntroduction:The mining industry has always been at the forefront of technological advancements, constantly seeking innovative solutions to extract valuable minerals efficiently and sustainably. Addressing this need, a ground-breaking product, commonly known as Flotation Cells (brand name removed), has emerged as a game-changer in ore processing techniques, transforming the way minerals are extracted from their ores. This article explores the features and benefits of these cutting-edge Flotation Cells, highlighting their potential to revolutionize the mining industry.I. The Power of Flotation CellsFlotation Cells utilize the principles of flotation to separate minerals from their host ores. This process involves mixing finely ground ore with water and chemical reagents to create a froth layer, which selectively attaches to the desired minerals. The froth is then skimmed off to produce a concentrate with a significantly higher concentration of the valuable minerals.Developed through years of research and development, the Flotation Cells offer several key advantages over conventional flotation systems. By incorporating advanced technologies and design enhancements, they have demonstrated remarkable improvements in productivity, efficiency, and environmental sustainability.II. Enhanced Performance and EfficiencyOne of the standout features of the Flotation Cells is their ability to handle significantly larger volumes of ore compared to traditional flotation equipment. This remarkable capacity allows mining operations to increase their throughput while reducing the number of cells required, ultimately resulting in substantial cost savings.Furthermore, the Flotation Cells' enhanced particle recovery mechanisms enable the extraction of smaller-sized particles that were once considered uneconomical. By ensuring higher recovery rates, these cells contribute to reduced wastage and increased profitability for mining companies.III. Advanced Design for Optimal OperationThe Flotation Cells' state-of-the-art design optimizes the mechanical and hydrodynamic parameters critical for successful flotation processes. With enhanced agitation and aeration capabilities, they ensure the homogeneous distribution of reagents and minerals across the cell, resulting in improved separation efficiency.The unique configuration of the Flotation Cells also facilitates easier cell maintenance and reduces downtime. The simplified design allows for swift access to essential components, ensuring quick repairs and replacements if necessary.IV. Enhanced Sustainability and Environmental ResponsibilityRecognizing the increasing importance of sustainable mining practices, the Flotation Cells have been developed with environmental considerations in mind. They significantly reduce the consumption of water and electricity, thereby minimizing the carbon footprint associated with the ore processing activities.Moreover, these cells also promote the usage of eco-friendly reagents, which are less harmful to the environment. By minimizing the use of toxic chemicals, the Flotation Cells align with the industry's commitment to reducing the impact on ecosystems while extracting valuable minerals responsibly.V. Economic Implications and Future ProspectsThe Flotation Cells' ability to enhance process efficiency, maximize recovery rates, and reduce environmental impact translates into substantial economic benefits for mining companies. Cost savings achieved through increased productivity and reduced operational expenditures can be reinvested into further research and development or used to improve overall sustainability measures.As the mining industry continues to evolve, the demand for advanced ore processing techniques remains paramount. The exceptional capabilities of Flotation Cells offer a glimpse into the future of mining, where optimized efficiency and sustainable practices converge to redefine the industry's standards.Conclusion:The Flotation Cells, developed with cutting-edge technology and engineering, represent a significant breakthrough in mineral processing. With enhanced performance, efficiency, and environmental responsibility, these cells exemplify the relentless pursuit of innovation within the mining industry. By transforming the way minerals are extracted from their ores, Flotation Cells have the potential to revolutionize the mining sector, empowering companies to extract resources more efficiently while minimizing their ecological impact.

Innovative Vertical Conveyor Belt Technology: A Game Changer in the Industry

In today's modern manufacturing industry, the use of innovative technology has revolutionized the way goods are transported and processed. One such technological advancement that has been making waves in the industry is the vertical conveyor belt. This cutting-edge machinery has the capacity to massively increase productivity and efficiency in various sectors such as warehousing, logistics, and manufacturing.The vertical conveyor belt, produced by a leading company in the industry, has been designed to streamline the process of moving goods in a vertical direction. Unlike traditional conveyor systems that are limited to horizontal movement, the vertical conveyor belt can transport goods to higher levels of a facility without the need for manual labor or heavy lifting equipment. This not only saves time and reduces the risk of worker injury, but also allows for a more efficient use of space within the facility.The company behind this groundbreaking technology, [], has been a trailblazer in the field of material handling solutions. With a strong focus on innovation and customer satisfaction, they have continuously pushed the boundaries of what is possible in the industry. The development of the vertical conveyor belt is just one example of their commitment to providing cutting-edge solutions that meet the evolving needs of their customers.Through extensive research and development, the company has engineered a vertical conveyor belt that boasts a number of impressive features. One such feature is its ability to handle a wide range of goods, from small, lightweight items to heavy, bulky loads. This versatility makes it an ideal solution for a variety of industries, including e-commerce fulfillment centers, distribution facilities, and manufacturing plants.Furthermore, the vertical conveyor belt is designed with efficiency in mind. By utilizing advanced automation and smart technology, it can optimize the flow of goods within a facility, reducing the need for manual intervention and maximizing throughput. This not only improves productivity, but also lowers operational costs and minimizes the risk of errors in the handling of goods.In addition to its practical features, the vertical conveyor belt is also built with the highest standards of safety and reliability. With robust construction and advanced safety features, it ensures the smooth and secure movement of goods, providing peace of mind to facility operators and workers alike.The potential impact of the vertical conveyor belt in the manufacturing and logistics industry is significant. By enabling the seamless movement of goods in a vertical direction, it opens up new possibilities for facility design and layout, allowing for more efficient use of space and resources. This, in turn, can lead to increased productivity and profitability for businesses that adopt this cutting-edge technology.As the demand for automation and efficiency in the manufacturing and logistics industry continues to grow, the vertical conveyor belt is poised to play a key role in shaping the future of material handling. With its ability to revolutionize the way goods are transported and processed, it is clear that this innovative technology will have a lasting impact on the industry as a whole.In conclusion, the vertical conveyor belt, developed by [], represents a leap forward in material handling technology. With its ability to transport goods in a vertical direction with unmatched efficiency and reliability, it is set to revolutionize the way businesses approach the movement of goods within their facilities. As the industry continues to embrace automation and smart technology, the vertical conveyor belt is sure to be at the forefront of this technological revolution.

Durable and Reliable Rubber Hoses: What You Need to Know

Rubber is a crucial element in the manufacturing of various products across multiple industries. Its versatility, durability, and flexibility make it an essential component in the production of automotive parts, industrial machinery, consumer goods, and more. {Company Name}, a leading provider of rubber solutions, is at the forefront of this innovative industry.{Company Name} has been a forerunner in the rubber manufacturing sector for over 20 years. They specialize in producing high-quality rubber products that are used in a wide range of applications. From custom molded rubber components to standard rubber parts, {Company Name} offers a comprehensive array of solutions to meet the diverse needs of their clients.One of the company's key offerings is their line of high-performance rubber hoses. These hoses are designed to withstand extreme conditions and are widely used in industries such as automotive, construction, and agriculture. Whether it's transporting fluids, gases, or granular materials, {Company Name}'s rubber hoses are engineered to deliver consistent performance and reliability.In a recent development, {Company Name} has introduced a new line of rubber hoses that are set to revolutionize the industry. These next-generation hoses are made from advanced rubber compounds that offer enhanced durability and resistance to abrasion, chemicals, and extreme weather conditions. This breakthrough in hose technology is expected to set a new standard for performance and longevity in various applications.The new rubber hoses are also designed to be highly flexible, making them easier to handle and install. This flexibility allows for easier maneuverability and reduces the risk of kinking and twisting, thereby extending the hose's lifespan. Moreover, these hoses have been engineered to maintain their flexibility even in low temperatures, offering reliable performance in diverse environmental conditions.{Company Name} has also incorporated innovative design features into the new rubber hoses to enhance their functionality. These include reinforced layers for added strength, leak-resistant fittings for secure connections, and ergonomic grips for ease of use. These thoughtful design elements reflect the company's commitment to delivering practical and user-friendly solutions to their customers.In addition to their technological advancements, {Company Name} is also dedicated to environmental sustainability. The new rubber hoses have been manufactured using eco-friendly processes and materials, reducing their carbon footprint and environmental impact. This eco-conscious approach aligns with the company's values and demonstrates their dedication to responsible manufacturing practices.The launch of the new rubber hoses reinforces {Company Name}'s position as an industry leader in rubber solutions. With their continued focus on innovation, quality, and sustainability, the company is poised to meet the evolving needs of their clients and remain at the forefront of the rubber manufacturing sector.As industries continue to evolve and demand for high-performance rubber products grows, {Company Name} stands ready to provide cutting-edge solutions that meet and exceed expectations. Their commitment to excellence, paired with their dedication to environmental responsibility, positions them as the preferred partner for businesses seeking reliable and sustainable rubber solutions.In conclusion, {Company Name} continues to push the boundaries of rubber technology with the introduction of their new line of high-performance rubber hoses. By combining advanced materials, innovative design, and a commitment to sustainability, the company is poised to deliver unparalleled value to their customers and make a lasting impact on the industry. As they look towards the future, {Company Name} remains dedicated to driving innovation and setting new standards for excellence in rubber manufacturing.

Durable and Reliable PVC Ball Valve for Many Applications

PVC Ball Valve is a type of valve that uses a spherical disc to control the flow of water, gas, or other fluids. It is one of the most commonly used valves in the plumbing industry due to its durability and ease of use. The PVC material makes it resistant to corrosion and chemical damage, making it suitable for a wide range of applications.One of the leading manufacturers of PVC Ball Valve is {} (), a company that has been producing high-quality valves for over two decades. They have gained a reputation for their commitment to excellence and innovation in the industry.The {} company has recently announced the launch of their latest PVC Ball Valve, designed to meet the growing demands of the market. The new valve features a unique design that offers improved performance and reliability, setting a new standard for the industry.The company's CEO, Mr. [Name], expressed his excitement about the new product, stating, "We are constantly striving to innovate and improve our products to better serve our customers. The new PVC Ball Valve is a testament to our dedication to providing the best possible solutions for our clients."The new PVC Ball Valve is available in a range of sizes to accommodate different piping systems, making it suitable for various applications in the plumbing and industrial sectors. Its compact and lightweight design also makes it easy to install and maintain, reducing overall costs for the end-user.In addition to its practical functionality, the new PVC Ball Valve from {} also meets industry standards for safety and environmental sustainability. The valve is designed to withstand high pressure and temperature, ensuring reliable performance in a wide range of operating conditions.Furthermore, the company's commitment to environmental responsibility is reflected in the manufacturing process of the PVC Ball Valve. {} utilizes advanced technologies and materials that minimize environmental impact while ensuring high-quality and durable products.In line with their dedication to customer satisfaction, {} also offers customizable options for the PVC Ball Valve to meet specific project requirements. Customers can choose from different handle types, connection methods, and other features to tailor the valve to their exact needs.The company also provides comprehensive technical support and after-sales service to ensure that customers can rely on the performance of the PVC Ball Valve for years to come. With a strong emphasis on customer satisfaction, {} has established a loyal and satisfied customer base over the years.The launch of the new PVC Ball Valve marks another milestone for {} as they continue to lead the industry in innovation and quality. Their commitment to excellence, environmental responsibility, and customer satisfaction sets them apart as a top choice for PVC Ball Valve solutions.As the demand for high-quality valves continues to grow, {} remains at the forefront of the industry, providing reliable and efficient solutions for various applications. The new PVC Ball Valve is a testament to their dedication to excellence and their ongoing efforts to meet the evolving needs of their customers.