How Conveyor Belt Technology is Transforming Manufacturing Processes

By:Admin

The new product, which has been developed after years of research and development, promises to offer improved performance, durability, and efficiency compared to existing conveyor systems. It is designed to meet the evolving needs of modern industries, delivering enhanced productivity and cost-effectiveness.

The Conveyor Belt has a proven track record of delivering cutting-edge conveyor solutions to a diverse range of industries, including manufacturing, logistics, food processing, and distribution. The company's commitment to innovation and customer satisfaction has earned it a reputation as a market leader in the field of material handling equipment.

In addition to its innovative products, The Conveyor Belt offers a comprehensive range of services, including conveyor system design, installation, maintenance, and support. The company's team of experienced engineers and technicians work closely with clients to develop customized solutions that meet their specific requirements.

The Conveyor Belt's dedication to quality and reliability is reflected in its state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. This enables the company to uphold the highest standards of manufacturing excellence and ensure that its products meet the most stringent performance and safety requirements.

Furthermore, The Conveyor Belt places a strong emphasis on sustainability and environmental responsibility in its operations. The company is committed to reducing its carbon footprint and minimizing its impact on the environment through the use of energy-efficient processes and materials.

With its unwavering commitment to excellence, The Conveyor Belt continues to set the benchmark for conveyor system innovation and performance. The company's relentless pursuit of technological advancement and customer satisfaction has cemented its position as a trusted partner for businesses looking to enhance their material handling capabilities.

The release of the new product demonstrates The Conveyor Belt's ongoing commitment to driving progress and innovation in the material handling industry. By leveraging its extensive expertise and resources, the company is poised to deliver a game-changing solution that will empower businesses to achieve new levels of operational efficiency and productivity.

As the global demand for advanced material handling solutions continues to grow, The Conveyor Belt is well-positioned to meet the evolving needs of industries around the world. The company's dedication to excellence, coupled with its relentless pursuit of innovation, makes it a formidable force in the competitive landscape of the material handling industry.

In conclusion, The Conveyor Belt's latest product release marks a significant milestone in the company's journey towards shaping the future of material handling. With its unwavering commitment to quality, innovation, and sustainability, The Conveyor Belt is poised to continue leading the way in delivering cutting-edge conveyor solutions for the evolving needs of modern industries.

Company News & Blog

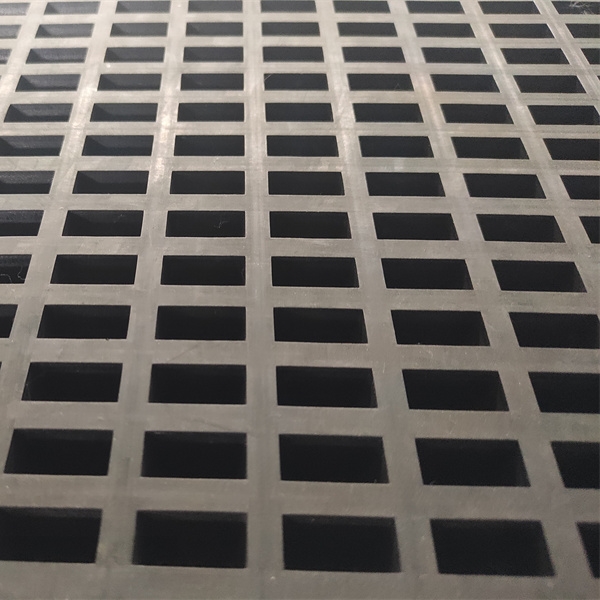

Discover the Advantages of Using a Reliable Sifting Screen Mesh

Title: Revolutionary Sifting Screen Mesh Introduces Cutting-Edge Innovation to Improve Industrial Materials SortingIntroduction:The materials sorting process has always been a crucial aspect of various industrial sectors. From mining and construction to food processing and recycling, the efficient separation of materials is vital for achieving high-quality end products. In a groundbreaking development, an innovative sifting screen mesh has been introduced by a renowned company dedicated to revolutionizing the materials sorting industry.Company Introduction: (Please provide specific details about the company to complete this section)[Company Name], a leading player in the materials sorting industry, has been at the forefront of developing advanced solutions for efficient and precise material separation. With decades of experience, cutting-edge research and development, and a commitment to customer satisfaction, [Company Name] has established itself as an industry leader.Main News Content:Para 1:[Company Name] has recently unveiled a new sifting screen mesh, designed to enhance the materials sorting process in various industries. The innovative mesh has been developed after extensive research and testing, aiming to address the common challenges faced by industrial operators during material separation.Para 2:Traditionally, materials sorting has relied on conventional meshes that are vulnerable to quick wear and tear, resulting in compromised efficiency and increased operational costs. However, the newly introduced sifting screen mesh is engineered to offer unparalleled durability, ensuring extended service life without compromising performance.Para 3:One of the key features that set this advanced mesh apart from its predecessors is its composition. The mesh is constructed from a unique blend of high-quality alloys that exhibit exceptional tensile strength, corrosion resistance, and anti-wearing properties. These characteristics enable the mesh to withstand the rigorous demands of industrial sorting operations, reducing the need for frequent replacements and repair.Para 4:The sifting screen mesh also incorporates a meticulously designed filtration system, aimed at optimizing sorting accuracy. The precisely engineered apertures ensure efficient separation of materials based on size, shape, and density, enabling operators to obtain consistent and high-quality end products. This improved accuracy significantly reduces material wastage and enhances productivity.Para 5:Moreover, [Company Name]'s sifting screen mesh is available in a wide range of mesh sizes, enabling customization to suit specific sorting requirements across various industries. This flexibility allows operators to achieve precise separation even with varied material types and particle sizes.Para 6:Recognizing the need for environmentally friendly solutions, [Company Name] has ensured that their sifting screen mesh is easily recyclable. By employing recyclable materials, the company demonstrates its commitment to sustainability, aligning with global efforts towards minimizing carbon footprints.Para 7:Additionally, [Company Name] offers comprehensive customer support services to ensure the seamless integration of the new sifting screen mesh into existing operations. Expert technicians provide guidance on installation, maintenance, and troubleshooting, ensuring optimized performance and prolonging the lifespan of the mesh.Para 8:Given the promising potential of the new sifting screen mesh, [Company Name] has already received overwhelmingly positive feedback from early adopters. The enhanced durability, accuracy, and sustainability of the mesh have attracted a significant number of industries seeking to improve their materials sorting processes.Conclusion:In an era where efficiency and sustainability are paramount, [Company Name]'s introduction of the revolutionary sifting screen mesh represents a significant leap forward in the materials sorting industry. By combining durability, accuracy, customization, and recyclability, this innovative product promises to optimize materials separation processes across various industrial sectors. As [Company Name] continues to push boundaries, it stands ready to revolutionize the way companies sort materials, ultimately contributing to increased productivity and decreased environmental impact.

Top-Quality Rubber Hoses for Industrial Use in the UK

A Heavy Duty Rubber Hose for Industrial ApplicationsRubber hoses are undeniably one of the most crucial components of any industrial setting. They are responsible for transporting various fluids, gases, or even solids from one point to another with ease and accuracy. Different industrial settings require various hose types, but for heavy-duty applications, a rubber hose is undoubtedly the go-to option.A heavy-duty rubber hose is a type of industrial hose designed to withstand demanding working conditions such as high temperatures, high pressure, abrasion, and harsh chemicals. These hoses are typically made of synthetic rubber materials that offer superior durability and resistance to wear and tear.The Importance of Heavy-Duty Rubber HosesHeavy-duty rubber hoses are used in a wide range of applications, including construction, mining, agriculture, marine, and automotive industries. These hoses are designed to handle complex and challenging applications, where typical hoses may fail to perform. Some common benefits of heavy-duty rubber hoses include:1. Durability: Heavy-duty rubber hoses are designed to withstand harsh conditions and provide extended service life. They have a higher resilience to abrasion, puncture, and cuts, making them ideal for heavy-duty applications.2. High-temperature resistance: Rubber hoses can handle a wide range of temperatures without experiencing any deformation or damage. This quality makes them ideal for applications requiring high-temperature resistance.3. Chemical resistance: Heavy-duty rubber hoses are highly resistant to various chemicals that would otherwise damage typical hoses. This makes them suitable for the transportation of various fluids, including acids and alkalis.4. Application versatility: Heavy-duty rubber hoses can be used in different industrial settings, including hydraulic systems, pneumatic systems, and water delivery systems.Selecting the Right Heavy Duty Rubber HoseWhen choosing a heavy-duty rubber hose, it's essential to consider the specific application requirements. Here are a few factors to consider when selecting a heavy-duty rubber hose:1. Pressure rating: Make sure the hose can handle the required operating pressure of the application. It's crucial to select a hose with a higher operating pressure than your application requires to avoid any damage or failure.2. Temperature rating: Consider the temperature range of the application to ensure the hose can withstand these temperatures.3. Hose diameter: The diameter of the hose determines its flow rate. Select a hose with the appropriate diameter to achieve optimal flow rate and performance in your application.4. Abrasion resistance: For applications with high abrasion, choose hoses with higher abrasion-resistant covers. This ensures the hose's extended service life in a demanding environment.ConclusionA heavy-duty rubber hose is a crucial component in many industrial applications. These hoses offer superior durability, resistance to wear and tear, temperature, and chemical resistance, and versatility. It's essential to choose the right heavy-duty rubber hose that meets specific application requirements to ensure optimal performance, safety, and durability. Whether you need hoses to transport fluids, air, or gas in industrial applications, a durable, heavy-duty rubber hose is the best option to consider.

Effective Ways to Keep Conveyor Belt Tracking Idlers in line

Conveyor Belt Tracking Idlers are designed to ensure that conveyor belts run straight and true, minimizing the chances of costly downtime and maintenance. These idlers are a crucial component in the efficient operation of conveyor systems in a wide range of industries, including mining, construction, agriculture, and manufacturing.{Company name} is a leading manufacturer of conveyor belt tracking idlers, with a strong reputation for producing high-quality products that deliver exceptional performance and durability. With over 20 years of experience in the industry, {Company name} has established itself as a trusted supplier to customers around the world.The key to the success of {Company name} lies in its commitment to innovation and continuous improvement. The company invests heavily in research and development, constantly seeking new ways to enhance the design and performance of its tracking idlers. This dedication to innovation has resulted in a range of products that are renowned for their reliability and effectiveness in keeping conveyor belts on track.One of the standout features of {Company name}'s tracking idlers is their unique design, which is carefully engineered to provide optimal belt alignment and stability. This is achieved through precise manufacturing processes and the use of high-quality materials, ensuring that the idlers can withstand the demanding conditions of heavy-duty conveyor applications.In addition to their exceptional performance, {Company name}'s tracking idlers are also designed with ease of installation and maintenance in mind. This makes them a practical and cost-effective choice for any conveyor system, as they help to minimize downtime and reduce the need for frequent adjustments and repairs.{Company name} takes pride in its ability to provide customized solutions to meet the unique requirements of its customers. The company's team of experienced engineers and technical experts work closely with customers to understand their specific challenges and develop tracking idlers that are tailored to their needs.The commitment to customer satisfaction is central to {Company name}'s business philosophy, and the company goes to great lengths to ensure that its products meet the highest standards of quality and performance. This dedication to excellence has earned {Company name} a loyal customer base and a strong reputation as a leader in the field of conveyor belt tracking idlers.Looking to the future, {Company name} is poised to continue its growth and success as a trusted supplier of conveyor belt tracking idlers. The company remains focused on innovation and continuous improvement, and is dedicated to delivering products that help customers to optimize the efficiency and reliability of their conveyor systems.In conclusion, {Company name} is a leading manufacturer of conveyor belt tracking idlers, with a strong reputation for producing high-quality products that deliver exceptional performance and durability. With a commitment to innovation, customer satisfaction, and continuous improvement, {Company name} is well positioned to provide customized solutions to meet the unique requirements of its customers, and to maintain its position as a trusted leader in the industry.

Durable High Pressure Rubber Hose for Various Applications

High Pressure Rubber Hose, a leading manufacturer of industrial hoses and rubber products, has recently introduced a new line of high pressure rubber hoses designed for various applications in the industrial and commercial sectors. With over 20 years of experience in the industry, High Pressure Rubber Hose has built a strong reputation for providing high-quality products and excellent customer service.The new line of high pressure rubber hoses is designed to meet the growing demand for durable and reliable hoses that can withstand high pressure and extreme conditions. These hoses are manufactured using the latest technology and high-quality materials to ensure superior performance and long-lasting durability. Whether it's for hydraulic systems, oil and gas drilling, mining, construction, or industrial machinery, High Pressure Rubber Hose offers a wide range of hose solutions to meet the diverse needs of its customers.One of the key features of the new line of high pressure rubber hoses is their ability to handle a wide range of temperatures and pressures, making them suitable for use in a variety of challenging environments. These hoses are also designed to withstand abrasion, corrosion, and other types of wear and tear, ensuring that they can withstand the rigors of industrial and commercial applications. In addition, they are flexible and easy to install, making them ideal for use in tight spaces and complex systems.High Pressure Rubber Hose is committed to providing its customers with the highest quality products and exceptional service. The company employs a team of skilled engineers and technicians who work tirelessly to ensure that each hose meets the highest standards of quality and performance. In addition, High Pressure Rubber Hose is dedicated to continuous research and development to stay at the forefront of innovation in the industry.In addition to its new line of high pressure rubber hoses, the company also offers custom hose solutions to meet the specific needs of its customers. Whether it's a unique hose design, a special material requirement, or a specific performance specification, High Pressure Rubber Hose can work closely with its customers to develop tailored solutions that meet their exact requirements. This commitment to customization sets High Pressure Rubber Hose apart from its competitors and makes it a trusted partner for companies seeking reliable hose solutions.High Pressure Rubber Hose is also dedicated to environmental sustainability and responsible manufacturing practices. The company adheres to strict quality control measures and environmental standards to ensure that its products are safe for the environment and its workers. Additionally, High Pressure Rubber Hose is committed to reducing its carbon footprint and minimizing waste in its manufacturing processes.With its new line of high pressure rubber hoses and its commitment to quality, innovation, and sustainability, High Pressure Rubber Hose is well-positioned to meet the evolving needs of the industrial and commercial sectors. The company's dedication to superior products and customer satisfaction makes it a trusted and reliable partner for companies seeking high-quality hose solutions.In conclusion, the introduction of the new line of high pressure rubber hoses further solidifies High Pressure Rubber Hose's position as a leader in the industry. With its dedication to quality, innovation, custom solutions, and environmental responsibility, the company continues to set the standard for excellence in industrial hose manufacturing. As the demand for durable and reliable hose solutions continues to grow, High Pressure Rubber Hose is poised to meet the needs of its customers with superior products and exceptional service.

Discover the Benefits of PVC Rubber for Custom Military Patches with Velcro Backing

Custom Military Patches: Why PVC Rubber Is Your Best Choice?Custom military patches are a great way to show affiliation, commemorate service, and recognize bravery. Whether you’re in the military, a veteran, or a civilian supporter, a high-quality patch can make a big difference. But when it comes to choosing the right material for your custom military patches, not all options are created equal.Enter PVC rubber, the material of choice for many military and law enforcement agencies around the world. In this article, we’ll explore why PVC rubber is the best choice for custom military patches, and why you should consider it for your next custom patch project.What is PVC Rubber?First, let’s define what PVC rubber actually is. PVC (polyvinyl chloride) is a synthetic plastic polymer that is widely used in a variety of industries, from construction to healthcare to fashion. In the case of custom patches, PVC rubber is created by injecting liquid PVC into custom molds, then allowing them to cool and solidify into a soft, flexible rubber material.PVC rubber is known for its durability, flexibility, and 3D texture. It can be molded into a variety of shapes, sizes, and colors, making it an ideal material for custom patches, labels, and keychains. And, unlike other materials that can fray, fade, or crack over time, PVC rubber is built to last, even in harsh environments.Why PVC Rubber is the Best Choice for Custom Military PatchesNow that we know what PVC rubber is, let's dive into why it's the best choice for custom military patches.1. DurableFirst and foremost, PVC rubber is incredibly durable. It’s resistant to water, chemicals, abrasions, and extreme temperatures, making it an ideal material for military patches that need to withstand harsh environments. Whether you're on the battlefield, in the line of duty, or simply need a patch that will last for years, PVC rubber delivers.2. 3D TexturePVC rubber allows for a 3D texture and a raised design, making your patch stand out in a crowded field of flat, low-quality patches. This is especially important for military patches, which often have detailed designs, text, and symbols that need to be clearly visible at all times.3. CustomizablePVC rubber can be easily molded into any shape, size, or color, making it ideal for custom patches. Whether you need a patch that matches your unit's colors, or a patch that includes your specific rank, PVC rubber can deliver. And, because it's a synthetic material, it can be colored to match any shade or hue.4. Velcro BackingMany military and law enforcement agencies prefer Velcro backing on their patches, as it allows for easy attachment and removal from tactical uniforms and gear. PVC rubber can be easily molded with Velcro backing, making it a seamless choice for these types of applications.5. Cost EffectiveFinally, PVC rubber is a cost-effective choice for custom military patches. While other materials may be more expensive, PVC rubber delivers a high-quality look and feel at an affordable price point. This makes it an ideal material for unit patches, morale patches, and other custom patches that need to be distributed in large quantities.Customized Rubber Accessories: Your Source for High-Quality PVC Military PatchesIf you’re looking for a reliable partner for your custom military patch project, look no further than Customized Rubber Accessories. At CRA, we specialize in creating high-quality PVC rubber patches, labels, and keychains for military and law enforcement agencies around the world.Our team of expert designers and craftsmen can help you create a custom patch that truly stands out, with detailed 3D designs, custom shapes and sizes, and Velcro backing for easy attachment. And, with quick turnaround times, affordable prices, and a commitment to quality, we’re the ideal choice for any custom patch project, large or small.In ConclusionPVC rubber is the clear choice for custom military patches, thanks to its durability, 3D texture, customizability, Velcro backing, and cost effectiveness. And with Customized Rubber Accessories as your partner, you can rest assured that your custom patches will be of the highest quality, designed to last for years of service and beyond. Contact us today to learn more about our services and get started on your custom military patch project!

How to Choose the Right Vacuum Hose for Your Needs

Title: Industry-Leading Rubber Vacuum Hose Enhances Performance and ReliabilityIntroduction:(Company Name), a renowned player in the manufacturing industry, is proud to introduce its premium rubber vacuum hose, a breakthrough product designed to enhance performance and reliability. This pioneering offering reinforces the company's commitment to delivering state-of-the-art solutions to satisfy the evolving needs of various industries.Rubber Vacuum Hose: A Game-ChangerIn a world increasingly reliant on advanced machinery and systems, it is crucial to have high-quality components that can withstand demanding conditions. The new rubber vacuum hose from (Company Name) emerges as a game-changer, offering unrivaled durability, flexibility, and superior performance across an array of applications.Unparalleled Durability:Manufactured using premium-grade rubber compounds and reinforced with innovative materials, this vacuum hose ensures exceptional durability even in the harshest working environments. Its resistance to abrasion, chemicals, and extreme temperatures significantly extends its lifespan, enabling prolonged and reliable operation.Enhanced Flexibility:Featuring a specially engineered design, the rubber vacuum hose guarantees excellent flexibility, which simplifies installation and maneuverability within complex systems. This enhanced flexibility reduces the risk of kinking or collapsing, thereby facilitating continuous and efficient vacuum operations.Superior Performance:The meticulous design and stringent quality control measures undertaken during its manufacturing process ensure that the rubber vacuum hose excels in performance. Its optimized internal diameter delivers unrestricted flow, minimizing friction loss and maximizing suction power. This characteristic ensures effective extraction, improving overall efficiency in a wide range of vacuum applications.Applications Across Industries:The unparalleled performance of this rubber vacuum hose makes it a versatile solution suitable for deployment across numerous industries. From automotive manufacturing and pharmaceuticals to industrial equipment and food processing, this innovative component successfully meets the diverse demands of these sectors, enhancing their operational efficiency.Automotive Manufacturing:In the automotive industry, the rubber vacuum hose is a vital component for various applications such as air intake systems, emission control, and braking systems. Its ability to withstand extreme temperatures and resist chemicals makes it an ideal choice, ensuring the optimal performance and reliability of critical automotive systems.Pharmaceutical and Medical Industries:Within the pharmaceutical and medical sectors, maintaining sterile environments is paramount. The rubber vacuum hose, with its resistance to abrasion and chemicals, is indispensable for vacuum conveying systems, pharmaceutical manufacturing, and medical equipment. Its flexibility and durability contribute to the seamless and hygienic transfer of sensitive substances and gases, ensuring adherence to strict quality standards.Industrial Equipment:In industrial settings, the rubber vacuum hose plays a crucial role in numerous applications such as material handling, pneumatic systems, and conveying bulk goods. Its resilience to harsh substances and external factors makes it an essential component for industrial equipment, ensuring uninterrupted production processes and optimal productivity.Food Processing and Packaging:The food processing and packaging industry require components that are compliant with stringent regulatory standards. The rubber vacuum hose, being food-grade certified, is an excellent choice for vacuum pumps, packaging lines, and material handling. Its ability to maintain product integrity and hygiene underscores its suitability for these critical processes.Conclusion:With its unparalleled durability, enhanced flexibility, and superior performance, (Company Name)'s rubber vacuum hose sets a new standard in the industry. Its versatile applications across automotive manufacturing, pharmaceuticals, industrial equipment, and food processing sectors make it an indispensable component that enhances efficiency and reliability. As a customer-centric company, (Company Name) continues to drive innovation, setting benchmarks in creating cutting-edge solutions that empower industries and contribute to their growth across the globe.

Uncover the Different Types of Bridge Expansion Joints for Enhanced Infrastructure

Title: Types of Bridge Expansion Joints: Enhancing Infrastructure Resilience and DurabilityIntroduction:As our society continues to evolve, the need to improve our infrastructure becomes even more crucial. One vital component of infrastructure development is the construction and maintenance of bridges. These structures must be designed to endure heavy traffic, harsh weather conditions, and ensure the safety of the traveling public. In this article, we will explore various types of bridge expansion joints that play a vital role in increasing bridge durability and reducing maintenance costs.1. Modular Joints:Modular joints are a widely used type of expansion joint in modern bridge construction. These joints consist of a series of steel-edge beams connected by elastomeric seals. By allowing controlled movement during thermal expansion and contraction, modular joints enhance the bridge's ability to withstand temperature variations. They also provide a smooth ride for vehicles, eliminate noise and vibrations, and reduce stress on the bridge deck.2. Finger Joints:Finger joints, also known as comb joints, are another popular type of expansion joint commonly found in bridge construction. These joints offer significant movement capability and are designed to accommodate horizontal and vertical displacements. Finger joints consist of multiple steel plates with interlocking fingers, enabling the bridge to flex while maintaining structural integrity. While versatile and cost-effective, finger joints require regular maintenance to prevent debris accumulation and ensuring optimal functionality.3. Sliding Plate Joints:Sliding plate joints, as the name suggests, incorporate sliding elements to facilitate bridge displacement while maintaining stability. These joints consist of two plates that glide over one another to accommodate expansion and contraction of bridge components. The sliding plate joints effectively alleviate stress on the bridge structure, reducing internal forces and minimizing the risk of damage caused by temperature fluctuation. Regular lubrication is essential to ensure the smooth functioning of sliding plate joints.4. Elastomeric Joints:Elastomeric joints are flexible and provide exceptional movement accommodation, making them suitable for use in both highway and railway bridges. These joints are constructed using flexible rubber-like materials combined with steel reinforcements. Elastomeric joints isolate vibrations and transmit vertical and horizontal movements between bridge sections, reducing the potential for structural damage and enhancing passenger comfort. Routine inspections and maintenance are vital to monitor the condition of the elastomeric material and ensure optimal performance.5. Selective Movement Joints:Selective movement joints are specialized for accommodating the differential movement between adjacent bridge sections. This type of expansion joint allows for various types of movement, including lateral and rotational motions. Selective movement joints often feature a combination of materials, such as rubber and metal, to achieve the required functionality. Regular inspections and maintenance are necessary to preserve the desired range of motion and prevent potential joint failure.Conclusion:Bridge expansion joints are a vital part of infrastructure design, allowing for flexibility and durability in the face of dynamic environmental conditions. By understanding the various types of expansion joints available, engineers can ensure long-lasting bridge structures that offer enhanced resilience, reduced maintenance costs, and improved user experience. Investing in proper maintenance and periodic inspections will help maintain the effectiveness of these joints and contribute to the longevity and safety of our vital transportation infrastructure.

Durable Slurry Hoses for Handling Abrasive Materials

Slurry hose and mud hose are crucial components in the operations of mines and quarries. They play a vital role in transporting abrasive and viscous slurries, which are byproducts of mining and quarrying activities. Without these hoses, the transportation of these materials would be challenging and costly.Recognizing the importance of slurry hoses and mud hoses, China's rubber industry has been actively manufacturing and supplying these vital components to various industries across the globe. China is a recognized hub for rubber production, and its manufacturers are renowned for their exceptional engineering expertise, high-quality materials, and user-friendly designs.One such manufacturer is [insert brand name], a leading supplier and manufacturer of slurry hoses and mud hoses. The company has been manufacturing and supplying these hoses for over a decade, providing exceptional service to its clients across the globe. By integrating the latest technology and consistently improving their manufacturing processes, they have been able to produce superior quality hoses at competitive prices.Slurry hoses are primarily designed to handle abrasive and viscous slurries. The hoses are made of high-quality blended rubber, which can withstand the abrasive nature of the materials, reducing the risk of wear and tear. The external bolt-on flanges design of the hoses allows for easy installation, uninterrupted free flow and makes maintenance much easier.Mud hoses, on the other hand, are designed to handle heavy mud and sludge materials. The hoses are made of premium quality materials that can withstand the heavy pressure of the materials transported. The smooth interior of the hose facilitates the smooth flow of materials, preventing blockages and ensuring a consistent flow.[Insert brand name] has gone beyond producing standard slurry hoses and mud hoses. The manufacturer also produces customized hoses to meet the specific needs of clients. Their team of experts utilizes the latest engineering software to design and produce hoses that are specific to individual requirements. Whether it is with regards to shape, length, or diameter, [insert brand name] always delivers quality hoses that meet the demands of the client.Quality is essential to the team at [insert brand name]. The company's professional team of engineers and technicians ensures that the manufacturing process follows strict guidelines and is compliant with international standards such as ISO and API. They use high-quality raw materials to ensure that the end product is durable, reliable, and safe.In addition to the superior quality of their products, [insert brand name] also prides itself on its exceptional customer service. The team is dedicated to providing excellent service to clients, ensuring that all their requirements are met promptly and efficiently. They have an excellent after-sales service, which ensures that clients receive the necessary support and assistance they require throughout the life of the product.The company also offers competitive pricing for their products without compromising on the quality. Their pricing strategy is aimed at providing affordable solutions to their clients without sacrificing the quality of their products. This strategy has played a considerable role in making [insert brand name] a preferred choice for clients across the globe.In conclusion, slurry hose and mud hose are essential components of the mining and quarrying industry. The quality of the hoses used can affect the productivity, cost, and safety of the operations. Investing in high-quality hoses from a reputable supplier such as [insert brand name] is crucial for any mining or quarrying operation. With their exceptional products, competitive pricing, and excellent customer service, [insert brand name] is a manufacturing industry leader that has become a trusted partner to clients worldwide.

Unique Roller Garland Ideas for Decorative Home Accents

Roller Garlands: A Revolutionary Solution for Material HandlingIn the fast-paced world of material handling, efficiency and productivity are key factors for success. Companies are constantly in search of innovative solutions that can help streamline their processes and improve their overall operations. This is where Roller Garlands come into play, offering a revolutionary solution to the challenges faced in material handling.{Company Name} is a leading provider of Roller Garlands, offering a wide range of high-quality products designed to improve material handling processes across various industries. With a strong focus on innovation, {Company Name} has developed Roller Garlands that are not only durable and reliable but also highly efficient, making them the go-to solution for companies looking to optimize their material handling operations.Roller Garlands are an essential component in conveyor systems, providing support and guidance to the conveyor belt as it moves materials from one point to another. They are designed to minimize friction and reduce wear on the conveyor belt, helping to extend its lifespan and improve overall performance. By utilizing Roller Garlands, companies can enhance the efficiency of their material handling processes, ultimately leading to increased productivity and cost savings.One of the key advantages of Roller Garlands is their modular design, which allows for easy installation and maintenance. This means that companies can quickly and easily integrate Roller Garlands into their existing conveyor systems, without having to invest in costly and time-consuming modifications. Additionally, the modular design makes it simple to replace individual rollers when necessary, minimizing downtime and ensuring continuous operation.Furthermore, {Company Name} offers a wide range of Roller Garlands to meet the specific needs of different applications. Whether it’s heavy-duty mining operations or light-duty manufacturing facilities, {Company Name} has a solution that can effectively handle the demands of the industry. Their extensive product line includes standard Roller Garlands, impact Roller Garlands, and custom-designed solutions, allowing companies to find the perfect fit for their unique material handling requirements.In addition to their exceptional product offerings, {Company Name} takes pride in its commitment to customer service and satisfaction. Their team of experts works closely with clients to understand their material handling challenges and provide tailored solutions that meet their specific needs. Whether it’s helping to design a new conveyor system or optimizing an existing one, {Company Name} is dedicated to delivering top-notch support and expertise every step of the way.As a testament to their commitment to quality and innovation, {Company Name} has invested heavily in research and development to continuously improve their Roller Garland products. This includes leveraging the latest technologies and materials to enhance performance and reliability, as well as conducting rigorous testing to ensure that their products exceed industry standards. By staying at the forefront of technological advancements, {Company Name} remains a trusted and reliable partner for companies looking to elevate their material handling capabilities.In conclusion, Roller Garlands offered by {Company Name} are revolutionizing the way companies approach material handling. With their unparalleled durability, efficiency, and flexibility, Roller Garlands have become an indispensable solution for companies across various industries. Whether it’s improving productivity, reducing maintenance costs, or enhancing overall performance, {Company Name} Roller Garlands are the key to unlocking the full potential of material handling operations. As companies continue to seek innovative solutions to stay ahead in the competitive market, Roller Garlands from {Company Name} are certain to play a pivotal role in shaping the future of material handling.