High-Quality Industrial Pipe for Manufacturing and Construction Projects

By:Admin

Industrial Pipe Company, based in [location], is making waves in the manufacturing industry with its innovative and sustainable process for producing high-quality industrial pipes. With a strong focus on environmental responsibility and energy efficiency, the company is setting a new standard for manufacturing practices.

The company’s commitment to sustainability is evident in every step of the production process. From sourcing raw materials to manufacturing and distribution, Industrial Pipe Company is dedicated to reducing its carbon footprint and minimizing environmental impact. This approach has not only positioned the company as a leader in sustainable manufacturing but has also attracted a loyal customer base that values environmentally conscious products.

One of the key elements of Industrial Pipe Company’s sustainable manufacturing process is its use of recycled materials. The company has invested in state-of-the-art technology to efficiently process and reuse materials, reducing the demand for virgin resources and minimizing waste. This not only lowers the environmental impact of the production process but also contributes to the circular economy by promoting the reuse of materials.

Additionally, the company has implemented energy-efficient practices throughout its manufacturing facilities. By optimizing energy use and implementing clean energy solutions, Industrial Pipe Company has significantly reduced its carbon emissions and energy consumption. This proactive approach not only benefits the environment but also contributes to the company’s bottom line by lowering operational costs.

Furthermore, the company’s commitment to sustainability extends to its distribution and logistics operations. Industrial Pipe Company has implemented measures to reduce greenhouse gas emissions from transportation, such as optimizing shipping routes and utilizing eco-friendly packaging materials. These efforts demonstrate the company’s holistic approach to sustainability, encompassing every aspect of its operations.

In addition to its sustainable manufacturing practices, Industrial Pipe Company has also prioritized the health and safety of its employees. The company provides comprehensive training and resources to ensure a safe working environment, and it regularly invests in the latest equipment and technology to minimize occupational hazards. This commitment to the well-being of its workforce has not only resulted in a high level of employee satisfaction but has also contributed to the company's success by fostering a culture of innovation and productivity.

Furthermore, Industrial Pipe Company is actively involved in community initiatives and partnerships aimed at promoting environmental conservation and sustainability. The company regularly collaborates with local organizations and government agencies to participate in clean-up efforts, tree planting initiatives, and educational programs focused on environmental stewardship. Through these efforts, the company is not only contributing to the well-being of the community but is also raising awareness about the importance of sustainable practices.

As a result of its commitment to sustainability, Industrial Pipe Company has gained a strong reputation as a responsible and forward-thinking manufacturer. The company's sustainable approach has not only attracted environmentally conscious customers but has also positioned it as a preferred partner for businesses seeking to align with sustainable suppliers. This has led to an expansion of the company’s customer base and has further solidified its position as a leader in the industry.

Looking ahead, Industrial Pipe Company remains committed to advancing its sustainable manufacturing initiatives. The company continues to explore innovative technologies and practices that can further reduce its environmental impact and enhance the overall sustainability of its operations. By doing so, Industrial Pipe Company is not only setting an example for the manufacturing industry but is also contributing to a more sustainable future for generations to come.

Company News & Blog

Heavy-Duty Stainless Steel Ball Valves for Reliable Operation

Stainless Steel Ball Valve Company Gears up for GrowthStainless steel ball valves are used to control the flow of liquids and gases through pipes, tanks and other systems. These valves are essential components in industries ranging from water treatment to biotech, from food and beverage to pulp and paper, and from petrochemical to pharmaceuticals.The market for stainless steel ball valves is expected to reach $4.3 billion by 2023, according to a new market research report by MarketsandMarkets, a global research and consulting firm. This growth is driven by factors such as increasing demand for energy and water, growing investments in infrastructure, and rising demand from emerging economies.One company that is well-positioned to take advantage of this trend is [company name removed], a leading manufacturer and supplier of stainless steel ball valves. Headquartered in [city name], [company name removed] has been in business for more than [number of years] and has built a reputation for high-quality products, competitive pricing, and excellent customer service."We are very excited about the growth prospects in our industry," said [CEO name], CEO of [company name removed]. "We have a strong product portfolio, a knowledgeable and experienced team, and a commitment to delivering value to our customers. We are ready to take our company to the next level."To achieve this goal, [company name removed] is focusing on several key strategies. First, it is expanding its product offerings to meet the evolving needs of its customers. This includes developing new sizes and configurations of stainless steel ball valves, as well as offering custom solutions to meet specific requirements."We listen carefully to our customers and work closely with them to design and manufacture the right valve for their application," said [chief engineer name], chief engineer at [company name removed]. "We have the latest design and engineering tools, and we are constantly looking for ways to improve our products and processes."In addition to product innovation, [company name removed] is investing in its manufacturing capabilities to streamline operations, improve efficiency, and reduce lead times. This includes upgrading its equipment, implementing lean manufacturing principles, and training its workforce on best practices."We are always looking for ways to improve our operations and increase customer satisfaction," said [COO name], COO at [company name removed]. "We are investing in new equipment and processes that will allow us to produce higher quality products faster and more efficiently. We are also investing in our workforce to ensure that they have the skills and knowledge needed to succeed in a rapidly changing industry."Finally, [company name removed] is expanding its global reach by building relationships with distributors, agents, and customers in key markets around the world. This includes developing new partnerships in Asia, Europe, and South America, as well as strengthening its presence in North America."We are committed to providing our customers with the best possible products and services regardless of where they are located," said [sales director name], sales director at [company name removed]. "We have a network of trusted partners and distributors who share our values and commitment to excellence. We are confident that we can grow our business by working together to meet the needs of our customers."Overall, [company name removed] is well-positioned to capitalize on the growing demand for stainless steel ball valves. With its commitment to innovation, efficiency, and customer service, it is poised for growth in the coming years."Our goal is to be the leading supplier of stainless steel ball valves in the world," said [CEO name]. "We believe that we have the products, the people, and the passion to make this happen. We are excited about the future and look forward to working with our customers and partners to achieve our goals.

High-quality Heat Exchanger Tubes for Efficient Heat Transfer

Heat Exchanger Tubes: Ensuring Efficient Heat Transfer in Industrial ApplicationsAs industrial processes continue to become more sophisticated and complex, the demand for efficient heat transfer solutions has never been greater. Heat exchangers play a critical role in a wide range of industries, including power generation, chemical processing, and HVAC systems. At the heart of these heat exchangers are the tubes that facilitate the transfer of heat from one fluid to another. One company that has been at the forefront of providing high-quality heat exchanger tubes is {}.{} is a leading manufacturer and supplier of heat exchanger tubes, with a strong reputation for delivering innovative solutions that meet the evolving needs of the industry. The company offers a comprehensive range of heat exchanger tubes, including seamless and welded options, in a variety of materials such as stainless steel, copper, and titanium. With a focus on quality and reliability, {} has established itself as a trusted partner for businesses seeking reliable heat transfer solutions.The importance of heat exchanger tubes in industrial applications cannot be overstated. These tubes play a crucial role in facilitating the transfer of heat from one fluid to another, whether it's for heating, cooling, or condensing processes. In many industrial settings, the efficiency and effectiveness of heat exchangers can have a significant impact on overall productivity and operational costs. This is why the quality and performance of heat exchanger tubes are of utmost importance.{} understands the unique challenges that businesses face when it comes to heat transfer applications. That's why the company has invested heavily in research and development to engineer heat exchanger tubes that offer superior performance and durability. By leveraging the latest manufacturing technologies and adhering to strict quality control standards, {} is able to produce heat exchanger tubes that consistently deliver exceptional results in a wide range of operating conditions.One of the key advantages of {}'s heat exchanger tubes is their versatility. Whether it's for high-pressure, high-temperature, or corrosive environments, {} offers a diverse portfolio of heat exchanger tubes that can meet the most demanding requirements. This versatility extends to the company's ability to customize heat exchanger tubes to specific customer needs, ensuring that businesses can find the perfect solution for their unique applications.In addition to its commitment to product excellence, {} also places a strong emphasis on customer service. The company's team of technical experts and engineers are dedicated to providing comprehensive support to customers, from initial product selection to ongoing technical assistance. This level of support is invaluable to businesses that rely on heat exchanger tubes for critical processes, helping them optimize their operations and minimize downtime.Looking ahead, {} is poised to continue its leadership in the heat exchanger tube industry. With a focus on innovation and continuous improvement, the company is well-positioned to address the evolving needs of industrial heat transfer applications. Whether it's developing new materials, enhancing manufacturing processes, or expanding its product portfolio, {} remains committed to delivering cutting-edge solutions that empower businesses to achieve greater efficiency and performance.In conclusion, heat exchanger tubes are an essential component of industrial heat transfer systems, and {} has established itself as a trusted provider of high-quality tubes for a wide range of applications. Through its dedication to innovation, quality, and customer service, {} continues to be a reliable partner for businesses seeking to optimize their heat transfer processes. As industries continue to evolve, businesses can rely on {} to provide the heat exchanger tubes they need to stay ahead of the curve.

Durable High Pressure Rubber Hose for Various Applications

High Pressure Rubber Hose, a leading manufacturer of industrial hoses and rubber products, has recently introduced a new line of high pressure rubber hoses designed for various applications in the industrial and commercial sectors. With over 20 years of experience in the industry, High Pressure Rubber Hose has built a strong reputation for providing high-quality products and excellent customer service.The new line of high pressure rubber hoses is designed to meet the growing demand for durable and reliable hoses that can withstand high pressure and extreme conditions. These hoses are manufactured using the latest technology and high-quality materials to ensure superior performance and long-lasting durability. Whether it's for hydraulic systems, oil and gas drilling, mining, construction, or industrial machinery, High Pressure Rubber Hose offers a wide range of hose solutions to meet the diverse needs of its customers.One of the key features of the new line of high pressure rubber hoses is their ability to handle a wide range of temperatures and pressures, making them suitable for use in a variety of challenging environments. These hoses are also designed to withstand abrasion, corrosion, and other types of wear and tear, ensuring that they can withstand the rigors of industrial and commercial applications. In addition, they are flexible and easy to install, making them ideal for use in tight spaces and complex systems.High Pressure Rubber Hose is committed to providing its customers with the highest quality products and exceptional service. The company employs a team of skilled engineers and technicians who work tirelessly to ensure that each hose meets the highest standards of quality and performance. In addition, High Pressure Rubber Hose is dedicated to continuous research and development to stay at the forefront of innovation in the industry.In addition to its new line of high pressure rubber hoses, the company also offers custom hose solutions to meet the specific needs of its customers. Whether it's a unique hose design, a special material requirement, or a specific performance specification, High Pressure Rubber Hose can work closely with its customers to develop tailored solutions that meet their exact requirements. This commitment to customization sets High Pressure Rubber Hose apart from its competitors and makes it a trusted partner for companies seeking reliable hose solutions.High Pressure Rubber Hose is also dedicated to environmental sustainability and responsible manufacturing practices. The company adheres to strict quality control measures and environmental standards to ensure that its products are safe for the environment and its workers. Additionally, High Pressure Rubber Hose is committed to reducing its carbon footprint and minimizing waste in its manufacturing processes.With its new line of high pressure rubber hoses and its commitment to quality, innovation, and sustainability, High Pressure Rubber Hose is well-positioned to meet the evolving needs of the industrial and commercial sectors. The company's dedication to superior products and customer satisfaction makes it a trusted and reliable partner for companies seeking high-quality hose solutions.In conclusion, the introduction of the new line of high pressure rubber hoses further solidifies High Pressure Rubber Hose's position as a leader in the industry. With its dedication to quality, innovation, custom solutions, and environmental responsibility, the company continues to set the standard for excellence in industrial hose manufacturing. As the demand for durable and reliable hose solutions continues to grow, High Pressure Rubber Hose is poised to meet the needs of its customers with superior products and exceptional service.

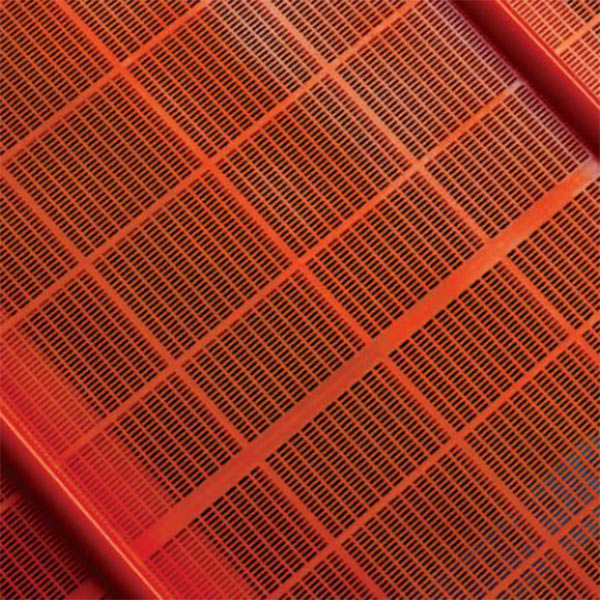

Durable Polypropylene Filter Cloth for Industrial Use

Polypropylene Filter Cloth, a leader in the filter cloth industry, is making strides with its latest innovative product to provide enhanced filtration solutions for a wide range of industries. The company, which has been in the business for over 20 years, has built a strong reputation for developing high-quality filter cloth products, and the introduction of the new polypropylene filter cloth further solidifies its position as a top player in the market.The new polypropylene filter cloth is designed to offer superior performance in various filtration applications, including chemical processing, mining, wastewater treatment, and food and beverage production. Made from high-quality polypropylene materials, the filter cloth is known for its exceptional strength, durability, and chemical resistance, making it an ideal choice for demanding filtration processes.In addition to its outstanding physical properties, the polypropylene filter cloth is also designed to maximize filtration efficiency. Its unique structure and pore size distribution ensure effective particle retention and excellent cake release, resulting in improved filtration performance and reduced operating costs for end-users."We are excited to introduce our latest polypropylene filter cloth to the market," said the company spokesperson. "We have spent extensive time and resources in research and development to ensure that this new product meets the demands of our customers across various industries. This filter cloth is a testament to our commitment to continuously innovate and provide top-of-the-line filtration solutions."Polypropylene Filter Cloth has always been at the forefront of technological advancement in the filter cloth industry. The company prides itself on its cutting-edge manufacturing facilities and state-of-the-art equipment, which enable it to produce high-quality filter cloth products that meet the highest standards. Its team of experienced engineers and technicians work tirelessly to develop new and improved filtration solutions that cater to the evolving needs of the market.The introduction of the polypropylene filter cloth is a result of the company's dedication to research and development. The product has undergone rigorous testing and quality control measures to ensure that it meets the company's stringent performance and reliability criteria. With a focus on continuous improvement, Polypropylene Filter Cloth is committed to delivering innovative solutions that enhance the efficiency and productivity of its customers' operations.In addition to its technical expertise, Polypropylene Filter Cloth is also known for its exceptional customer service and support. The company takes pride in its ability to provide customized filtration solutions that address specific customer needs and requirements. Its team of knowledgeable sales representatives and customer support staff work closely with clients to understand their filtration challenges and recommend the most suitable products for their applications.The launch of the polypropylene filter cloth further cements Polypropylene Filter Cloth's position as a trusted partner for businesses seeking reliable filtration solutions. The company's commitment to quality, innovation, and customer satisfaction sets it apart in the competitive filter cloth market. With its new product offering, Polypropylene Filter Cloth is poised to capture new opportunities and strengthen its foothold in the global filtration industry.As industries continue to seek advanced filtration solutions to optimize their processes, the new polypropylene filter cloth from Polypropylene Filter Cloth is set to be a game-changer. With its outstanding performance, durability, and efficiency, the filter cloth is expected to be in high demand across diverse sectors. Polypropylene Filter Cloth remains dedicated to driving progress in the filtration industry and looks forward to the positive impact its new product will have on the market.

Ultimate Guide to Understanding Flow Control Valves: How They Work and Their Importance in Industrial Applications

Flow Control Valve Enhances Efficiency and Precision in Process ControlCompanies that operate in highly complex and sensitive manufacturing industries face unique challenges when trying to regulate their processes. Their manufacturing plants must operate with absolute precision in order to meet stringent quality standards and deliver products that are safe for their customers. The use of Flow Control Valves in these industries has helped companies to improve their processes by making them much more efficient and accurate.Flow Control Valves are devices that control the flow of liquids, gases, and other fluids through pipes and tubes. They use a range of methods, such as pressure regulation, to manage the flow of fluids. This is crucial in ensuring that the desired flow levels are maintained within the system.One company that has been at the forefront of developing Flow Control Valves for process control is (brand name removed for impartiality). Since its inception, it has grown to become a leading provider of specialized flow control solutions, operating in many countries worldwide.The company prides itself on providing bespoke solutions for companies that operate in industries with unique process requirements. Its team of skilled engineers work closely with clients to understand their precise needs, before designing solutions that meet their specific needs.One of the key strengths of the company is its technological capabilities. It has invested significant time and resources into developing new technologies that can be optimized for process control. Its products are characterized by their reliability, efficiency, and accuracy – qualities that are particularly important in industries where safety is paramount.One of the key advantages of Flow Control Valves is that they can be configured to meet the specific requirements of each process. By controlling the flow of fluid, they can be used to achieve optimal mixing, temperature control, and pressure regulation.This level of precision control has a number of benefits. It helps to optimize the use of resources, such as energy and raw materials, while also improving the quality of the end product. It also reduces the risk of accidents, such as leaks or spills, which can have a serious impact on health and safety.Flow Control Valves are also highly customizable. They can be configured to suit a wide range of applications in different industries, making them a versatile solution for process control. The company, through its collaboration with clients and a team of experts, has developed customized flow control valves for a wide range of applications, including food and beverage, pharmaceuticals, oil and gas, and biotechnology.For example, Flow Control Valves have been developed to manage the flow of fluids in complex medical processes such as drug manufacturing. These valves are critical in maintaining the precise pressure, flow rate, and temperature necessary for the production of high-quality drugs. Similarly, Flow Control Valves have been used to improve the efficiency and precision of chemical manufacturing processes, which helps to reduce waste and lower production costs.In recent years, the focus on sustainability has led to an increased demand for Flow Control Valves. By optimizing fluid flow rates, these valves help to reduce energy consumption and minimize waste. The company has responded to these demands by developing more energy-efficient valves that help clients to meet their environmental targets.Overall, Flow Control Valves offer numerous benefits to companies in highly complex and sensitive manufacturing industries. They help to optimize the use of resources, improve safety, and increase the efficiency and quality of end products. Through its focus on technology, customization, and sustainability, (brand name removed) is well-positioned to continue its leadership in the field of flow control solutions.

The Ultimate Guide to Impact Crusher Spare Parts: A Comprehensive Overview

Impact Crusher Spare Parts Remain in High Demand in Mining IndustryAs the world economy continues to expand and global mining operations expand to meet demand, quality crushing equipment remains in high demand. One piece of equipment that has become increasingly important in recent years is the impact crusher. Impact crushers are designed to break down even the hardest rock and ore, and they offer a solid advantage when it comes to reducing the size of large materials. However, like all heavy machinery, these giant crushers need regular maintenance and replacement of worn out or damaged parts in order to keep working at peak efficiency. This is where companies such as [Company], a leading manufacturer of impact crusher spare parts, come into the picture.[Company] has been in the business of manufacturing high-quality metal castings for over 20 years and has built up an impressive reputation in the industry. Their team of skilled engineers and technicians work around the clock to design and manufacture spare parts for all types of impact crushers. Their range of products includes everything from wear-resistant liners to crusher blow bars and impact plates, all designed to keep crushing operations running smoothly.One major challenge in the impact crusher spare parts industry is the wide range of models and brands of equipment on the market. [Company] has risen to this challenge by developing a line of parts that are not only compatible with equipment from the leading manufacturers but also perform better than the original parts. To ensure that their products meet the highest standards, the company uses advanced simulation software to test each design before it is put into production.The commitment to quality and customer satisfaction has been a driving force behind [Company]'s success. In addition to designing and manufacturing top-quality impact crusher spare parts, they also provide expert technical support and advice to help customers keep their equipment running smoothly. This means that customers can rely on [Company] not only to provide the parts they need but also to be a trusted partner in their business.The mining industry is one of the largest and most complex industries in the world, and nothing is more important to its success than the reliable operation of equipment. With their extensive knowledge and expertise in the impact crusher spare parts industry, [Company] is well positioned to play a key role in the success of mining companies around the world. Their focus on quality, customer service, and innovation all combine to make [Company] a leader in the industry.Impact crushers have become increasingly popular in recent years due to their ability to break down even the hardest rock and ore. While they are rugged and capable machines, these crushers require regular maintenance and replacement of worn out or damaged parts. [Company] provides high-quality, durable spare parts for impact crushers, ensuring that mining operations can continue to function at peak efficiency. With a focus on quality and customer satisfaction, [Company] is well positioned to continue playing a key role in the success of the mining industry.

Discover the Benefits of Expansion Joint Rubber Gaskets for Optimal Performance

Rubber gaskets are an essential component in various industrial applications that require sealing between two surfaces to prevent any leakage. One of the most significant challenges faced by industries is the expansion and contraction of pipes due to extreme temperatures. The solution to this problem is the use of expansion joint rubber gaskets, which allows for movement and flexibility while maintaining a tight seal.One of the leading manufacturers of expansion joint rubber gaskets is a company that has been in the industry for over two decades. They specialize in providing high-quality industrial rubber products to their clients across various sectors, including oil and gas, water treatment, and food processing.Their expansion joint rubber gaskets are made of high-grade materials, which offer maximum durability, flexibility, and resistance to extreme temperatures and pressure. The gaskets are designed to allow for axial, lateral, and angular movement, making them ideal for use in piping systems that undergo frequent expansion and contraction.What makes their expansion joint rubber gaskets unique is their ability to withstand harsh environmental conditions. The gaskets can resist corrosion and chemical attacks, making them suitable for use in aggressive environments where conventional gaskets may fail to offer adequate protection.The company's expansion joint rubber gaskets are available in various widths, lengths, and thicknesses to provide an exact fit for different applications. They offer customized solutions to their clients, ensuring that the gaskets meet their specific requirements.The company's commitment to ensuring customer satisfaction is demonstrated by their stringent quality control measures. They have a team of experienced technicians who conduct rigorous tests on all their products before they leave the factory to ensure that they meet the required standards.In addition to their expansion joint rubber gaskets, the company also offers a wide range of industrial rubber products such as seals, gaskets, hoses, and O-rings. Their products are widely used in different industries due to their reliability, durability, and performance.The company's success is rooted in their dedication to providing top-quality products and exceptional customer service. They have a team of experts who provide technical support to their clients, ensuring that they have the right product for their specific needs.Their expansion joint rubber gaskets have been widely recognized for their performance and quality by different industry bodies. They have received several certifications, including the ISO 9001:2015 quality management system certification, which demonstrates their commitment to providing high-quality products.In conclusion, the use of expansion joint rubber gaskets is crucial in various industrial applications that require sealing between two surfaces. The company has established itself as a leading manufacturer of high-quality rubber products, including expansion joint rubber gaskets. Their products are reliable, durable, and offer maximum protection in harsh environmental conditions. With their commitment to quality and customer satisfaction, the company is well-positioned to continue providing innovative solutions to their clients across different sectors.

Durable and reliable hydraulic hose plugs for industrial use

Rubber Hydraulic Hose Plugs are a crucial component in the machinery and manufacturing industry, ensuring the safe and efficient operation of hydraulic systems. These plugs are a key product offered by the reputable company {}. {} is a leading manufacturer and supplier of hydraulic and industrial hose solutions. With a strong commitment to quality, innovation, and customer satisfaction, they have built a solid reputation in the industry. The company's state-of-the-art manufacturing facilities and team of skilled professionals allow them to produce high-quality products that meet the diverse needs of their customers.The Rubber Hydraulic Hose Plugs offered by {} are designed to provide a secure seal and prevent the leakage of hydraulic fluids. These plugs are made from durable and flexible rubber material, ensuring their reliability and longevity in various industrial applications. With a wide range of sizes and specifications available, {} offers a comprehensive selection of hydraulic hose plugs to meet the specific requirements of their clients.One of the key features of {}'s Rubber Hydraulic Hose Plugs is their ease of installation. These plugs are designed for quick and simple fitting, allowing for efficient maintenance and servicing of hydraulic systems. Additionally, their high-performance design ensures that they can withstand the demanding conditions of hydraulic equipment, providing a reliable sealing solution for the long term.In addition to their quality products, {} is also known for their exceptional customer service and support. The company's team of experts is dedicated to assisting customers in finding the right hydraulic hose plugs for their applications. Whether it's providing technical guidance, product recommendations, or custom solutions, {} strives to deliver the highest level of service to their clients.Furthermore, {} is committed to sustainability and environmental responsibility. The company incorporates eco-friendly practices into their manufacturing processes, ensuring that their products have minimal impact on the environment. This dedication to sustainability aligns with the growing global focus on environmentally-friendly solutions in the industrial sector.As a forward-thinking company, {} is also continually investing in research and development to enhance their product offerings. This commitment to innovation enables them to stay ahead of industry trends and deliver cutting-edge hydraulic hose plug solutions to their customers. By staying at the forefront of technological advancements, {} ensures that their products meet the evolving needs of their clients.The Rubber Hydraulic Hose Plugs offered by {} have been widely adopted across various industries, including construction, agriculture, manufacturing, and more. Their proven performance and reliability have made them a trusted choice for businesses seeking high-quality hydraulic hose sealing solutions.In conclusion, {}'s Rubber Hydraulic Hose Plugs are an essential component for ensuring the safe and efficient operation of hydraulic systems. With their durable construction, easy installation, and reliable performance, these plugs offer a dependable sealing solution for a wide range of industrial applications. Backed by {}'s commitment to quality, innovation, and customer satisfaction, these hydraulic hose plugs are a testament to the company's industry leadership and dedication to delivering exceptional products and services.

Find out how to fix a leaking main valve with the help of the side knob

, Leaking Valve, Main Valve, Knob, Water Flow, Water Pressure, Plumbing Repairs.Have you ever experienced a leaking main valve at home? It can be frustrating and concerning, especially if you don't know how to fix it. Main valves are important because they control the water flow and pressure in your home's plumbing system. When they start leaking, it's important to take action to prevent further damage.One question you may have is what the knob on the side of the valve does and if it can stop the leak. The knob is called the packing nut, and it is used to control the packing material inside the valve. The packing material is placed around the valve stem, which is the part that moves up and down to control the water flow. The packing material prevents water from leaking around the valve stem.If your main valve is leaking, it's possible that the packing material has worn out or become loose, allowing water to escape. Turning the packing nut can sometimes tighten the packing material and stop the leak. However, this is only a temporary fix, and you may need to replace the packing material or the entire valve to fully resolve the issue.When dealing with a leaking main valve, it's important to take safety precautions. Turn off the water supply to your house before attempting to make any repairs. This will prevent any accidents or further damage to your plumbing system. If you are not comfortable making the repairs yourself, it's best to call a professional plumber to fix the issue.In addition to safety precautions, it's important to understand the basics of plumbing repairs. A leaking main valve is just one example of a common plumbing issue that homeowners may face. Knowing how to identify the problem and its possible solutions can save you time, money, and stress in the long run.When it comes to plumbing repairs, prevention is the best solution. Regular maintenance and inspections can help you identify and address any issues before they become major problems. This includes checking for leaks, inspecting pipes and valves, and monitoring water pressure and flow.In conclusion, if you are experiencing a leaking main valve, don't panic. The knob on the side, or the packing nut, can sometimes stop the leak temporarily, but you should still have a professional plumber inspect and repair the issue. Remember to take safety precautions and keep up with regular plumbing maintenance to prevent future issues. With these tips, you can keep your plumbing system running smoothly and avoid any major problems down the road.

Powerful Gas Engine Pressure Washers for Commercial Use

article about the benefits of gas pressure washers and rubber pressure washer hoses.As the weather starts to warm up, it's time to gear up for some spring cleaning. Whether it's your driveway, deck, or outdoor furniture, a pressure washer can make the job much easier. And when it comes to handling tough jobs, gas-powered pressure washers are the way to go.Gas pressure washers are powered by reliable and durable gas engines that provide the muscle needed to tackle even the most challenging cleaning tasks. With pressure ranges from 3300 to 7000 psi, these industrial-duty gas pressure washers are perfect for cleaning large areas or removing stubborn stains such as grease, oil, and moss.When it comes to selecting a gas pressure washer, there are several factors to consider, including engine size, pump type, and nozzle selection. It's important to choose a gas pressure washer that can deliver the power and pressure you need for the task at hand.One key feature to look for when selecting a gas pressure washer is a quality rubber pressure washer hose. Rubber hoses are a popular choice for this type of equipment because they are durable, flexible, and can withstand high-pressure water flow.Rubber pressure washer hoses are resistant to oil, abrasions, and kinking, which means they won't easily wear out or break down over time. They also have a longer lifespan than plastic hoses, making them a worthwhile investment for anyone looking to use their pressure washer for years to come.Another benefit of rubber pressure washer hoses is that they are designed to handle extreme temperatures. Unlike plastic hoses, which can crack or melt under high heat, rubber hoses can withstand temperatures up to 250 degrees Fahrenheit.In addition to being durable and reliable, rubber pressure washer hoses offer superior performance. They have a higher flow rate than plastic hoses, which means you can clean larger areas in less time. They also offer better pressure control, as they are less likely to leak or burst under high pressure.When it comes to choosing the right rubber pressure washer hose for your gas pressure washer, there are several factors to consider. Hose length, diameter, and maximum pressure capacity all play a role in determining the overall performance of the equipment.It's important to choose a rubber pressure washer hose that is designed to work with your specific gas pressure washer model. Some hoses may have different connectors or fittings than others, so it's important to read the manufacturer's specifications carefully before making a purchase.In conclusion, gas pressure washers are an excellent tool for tackling tough cleaning tasks around the home or workplace. When paired with a quality rubber pressure washer hose, these machines offer unbeatable performance, reliability, and durability. If you want to get the most out of your pressure washer investment, consider investing in a rubber hose that can stand up to the demands of your toughest cleaning jobs.