How a Manual Slide Valve Works and Its Benefits

By:Admin

The Manual Slide Valve is a key component in the control and regulation of fluid and gas flow within industrial settings. It is commonly used in a wide range of applications such as in the oil and gas industry, petrochemical plants, water treatment facilities, and many other industrial operations. The valve's ability to accurately control the flow of various media makes it an essential tool in ensuring the smooth and efficient operation of industrial processes.

The Manual Slide Valve comes in a variety of sizes and configurations to accommodate different flow rates and pressure requirements. The valve is designed to be durable and reliable, capable of withstanding harsh operating conditions and providing consistent performance over an extended period of time. Its simple yet effective design allows for easy installation and maintenance, making it a cost-effective solution for businesses looking to improve their operations.

One of the key features of the Manual Slide Valve is its precise control capabilities. The valve is designed to provide accurate and repeatable control of fluid and gas flow, allowing for precise regulation of process conditions. This level of control is essential in ensuring the quality and safety of industrial operations, as well as in optimizing the efficiency of production processes.

In addition to its control capabilities, the Manual Slide Valve is also known for its reliability. The valve is built to withstand the demands of industrial operations, with a robust construction that ensures its longevity and consistent performance. This reliability is crucial in maintaining the safety and productivity of industrial processes, as well as in minimizing downtime and maintenance costs.

Furthermore, the Manual Slide Valve is designed with user-friendliness in mind. Its simple and intuitive operation allows for easy adjustment and control, empowering operators to tailor the valve's performance to meet the specific requirements of their processes. This level of flexibility and ease of use makes the valve a valuable tool for businesses looking to optimize their operations.

With all these features and capabilities, it's no wonder that the Manual Slide Valve has become a preferred choice for many businesses and industries. Its impact on industrial processes has been significant, contributing to improved efficiency, safety, and productivity across various sectors. Furthermore, the valve's reputation for quality and reliability has solidified its position as a trusted and essential component in the industrial equipment market.

As a leading manufacturer in the industry, {} takes pride in producing high-quality industrial equipment that meets the needs of businesses and industries worldwide. With a commitment to innovation and excellence, they have continued to develop and refine their products to ensure that they meet the evolving demands of the market. The Manual Slide Valve is just one example of their dedication to providing superior solutions for industrial processes, and it serves as a testament to their ongoing success and leadership in the industry.

In conclusion, the Manual Slide Valve has undoubtedly made its mark in the industrial equipment market, offering businesses and industries an effective and reliable solution for controlling fluid and gas flow. With its precision, reliability, and user-friendly design, the valve has become an essential tool in optimizing industrial processes and ensuring the safety and efficiency of operations. As the leading manufacturer in the industry, {} continues to set the bar for quality and innovation, driving the advancement of industrial equipment and supporting businesses worldwide.

Company News & Blog

Popular Butterfly Valve: A Reliable Solution for Flow Control

Butterfly Valve Offers Innovative Solution for Industrial ApplicationsIn a world where efficiency is key, companies are constantly seeking innovative solutions to improve their industrial processes. One such solution, offered by {Company Name}, is the butterfly valve. This valve is designed to regulate flow in a pipeline, making it an essential component for a wide range of industrial applications.A butterfly valve operates through the use of a disc that rotates around a central axis, allowing for a quick and efficient shut-off in a pipeline. This design provides a significant advantage over other types of valves, as it allows for a full bore flow with minimal pressure drop. This makes the butterfly valve an ideal choice for applications where space and weight are limited, such as in the automotive, aerospace, and marine industries.{Company Name}, a leading manufacturer of industrial valves, has been at the forefront of innovation in the industry for over 50 years. With a strong focus on research and development, the company has consistently delivered high-quality products that meet the evolving needs of their customers. Their line of butterfly valves is no exception, offering a range of options to suit various industrial applications.One of the key features of the butterfly valve offered by {Company Name} is its versatility. The valve can be used for various types of media, including gas, air, water, and corrosive liquids. This makes it an excellent choice for industries such as oil and gas, chemical processing, and water treatment. Additionally, the valve can be configured for manual, electric, or pneumatic actuation, providing flexibility and ease of use for operators.Another notable advantage of the butterfly valve is its low maintenance requirements. The simplicity of its design means that it is less prone to wear and tear compared to other types of valves, reducing the need for frequent maintenance and repairs. This not only saves time and resources for companies, but also ensures consistent performance and reliability in their industrial processes.Furthermore, {Company Name} offers customizable solutions for their butterfly valves, allowing customers to tailor the valve to their specific requirements. This includes options for different materials, sizes, and pressure ratings, ensuring that the valve can meet the demands of even the most challenging applications. Their team of experts works closely with customers to understand their needs and provide tailored solutions that guarantee optimal performance.In addition to their commitment to quality and innovation, {Company Name} places a strong emphasis on sustainability. Their butterfly valves are designed with energy-efficient features, helping companies minimize their environmental impact. By reducing pressure drop and optimizing flow control, the valve contributes to improved energy efficiency in industrial processes, aligning with the global push for sustainable practices.As industries continue to evolve and adapt to changing demands, the butterfly valve offered by {Company Name} presents an invaluable solution for enhancing efficiency and performance. With its versatility, low maintenance requirements, and customizable options, the valve is well-positioned to meet the diverse needs of various industrial applications.In conclusion, the butterfly valve offered by {Company Name} stands as a testament to their commitment to innovation and quality. As industries continue to embrace new technologies and solutions, the butterfly valve is poised to play a crucial role in enhancing industrial processes, driving efficiency, and meeting the evolving needs of customers. With a strong focus on sustainability and customer-centric solutions, {Company Name} is well-equipped to lead the way in delivering cutting-edge industrial valves for years to come.

Efficient and Reliable Conveyor Systems for Optimal Drum Handling

Title: Efficient and Automated Conveyor Systems Optimizing Industrial OperationsIntroduction:In recent years, the demand for efficient and automated conveyor systems has grown exponentially across various industries. These systems have become an integral part of industrial operations, ensuring seamless material handling and increased productivity. One prominent company contributing to this sector is Drum Conveyor Systems (name removed), a leading manufacturer and supplier of cutting-edge conveyor solutions.I. Background of Drum Conveyor Systems:Drum Conveyor Systems has established itself as a pioneer in the field, consistently delivering top-quality conveyor systems that meet the diverse needs of its clients. With extensive experience and expertise in manufacturing, the company has gained a reputation for providing innovative and customized solutions while adhering to the highest industry standards.II. Advanced Features and Technology:With a strong focus on research and development, Drum Conveyor Systems continuously invests in advanced technologies to enhance the functionality and efficiency of their conveyor systems. These systems are designed to handle a wide range of materials, including heavy loads, while ensuring minimal downtime and maximum throughput.One of the key features of Drum Conveyor Systems' solutions is their modular design, allowing for easy installation and integration into existing production lines. The modular approach enables customization based on specific operational needs, facilitating seamless material flow within industrial environments.Moreover, the company has embraced Industry 4.0 principles and leveraged cutting-edge automation technologies. Drum Conveyor Systems' conveyor solutions are equipped with intelligent sensors and programmable logic controllers (PLCs) to optimize material handling processes. These systems can be seamlessly integrated with other machinery and are capable of real-time monitoring and data exchange, allowing for smoother operations and proactive maintenance.III. Application of Drum Conveyor Systems' Conveyor Solutions:Drum Conveyor Systems caters to a diverse range of industries, including manufacturing, logistics, food processing, and automotive, among others. Their solutions have been deployed in warehouses, distribution centers, assembly lines, and airports, revolutionizing material handling processes.In the manufacturing sector, Drum Conveyor Systems' conveyor solutions efficiently transport raw materials between workstations, allowing for streamlined production and minimizing worker fatigue. These systems ensure consistent and accurate supply of materials, reducing the risk of errors and enhancing overall productivity.In the logistics industry, their conveyors facilitate the movement of goods from one location to another, improving order fulfillment processes and reducing manual handling. The advanced features provided by Drum Conveyor Systems, such as integrated barcode scanners and automated sorting mechanisms, contribute to faster and error-free order processing.Within the food processing industry, Drum Conveyor Systems' sanitary design conveyor solutions ensure compliance with strict hygiene standards. The stainless-steel construction and easy-to-clean features prevent cross-contamination and enable thorough sanitation, enhancing food safety and preventing product recalls.IV. Commitment to Sustainability:Drum Conveyor Systems recognizes the importance of sustainable practices in today's industrial landscape. The company is actively involved in the development of energy-efficient conveyor systems, utilizing eco-friendly materials and implementing energy-saving technologies. By reducing energy consumption and minimizing waste, they contribute to both environmental preservation and cost savings for their customers.V. Conclusion:With an unwavering commitment to innovation and customer satisfaction, Drum Conveyor Systems has emerged as a global leader in providing cutting-edge conveyor solutions. From their advanced features to their wide range of applications, Drum Conveyor Systems' offerings play a crucial role in optimizing material handling processes across various industries. As the demand for efficient and automated conveyor systems continues to grow, the company remains at the forefront, consistently raising the bar for excellence in the field.

High-Quality Custom Nylon Parts for Your Needs

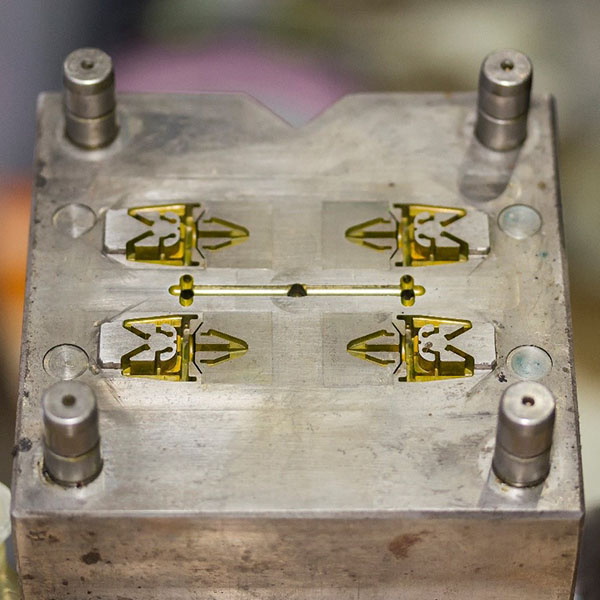

Custom made nylon parts are gaining popularity among industries due to their versatility and durability. One company at the forefront of producing these high-quality nylon parts is {}. With a strong focus on innovation and customer satisfaction, {} has been providing top-notch custom nylon parts to a wide range of industries.Established in {}, {} has quickly become a leading manufacturer of custom nylon parts. The company's state-of-the-art facility is equipped with the latest technology and machinery, allowing them to meet the diverse needs of their clients. Whether it's a small batch of parts for a specific project or a large-scale order for mass production, {} has the capabilities to deliver high-quality nylon parts with precision and efficiency.One of the key advantages of custom made nylon parts is their versatility. Nylon is a strong and durable material that can be molded and shaped to fit a variety of specifications. This makes it an ideal choice for industries such as automotive, aerospace, electronics, and more. {} understands the unique requirements of each industry and works closely with their clients to develop customized solutions that meet their exact needs.In addition to their versatility, custom nylon parts offer excellent resistance to wear and tear, making them a cost-effective choice for many applications. Whether it's for machinery components, industrial equipment, or consumer products, nylon parts manufactured by {} are designed to withstand the harshest of conditions and provide long-lasting performance.{} takes pride in their commitment to quality and customer satisfaction. Their team of skilled engineers and technicians work closely with clients from the initial concept stage through to the final production, ensuring that the custom nylon parts meet the highest standards of performance and reliability. With a focus on continuous improvement and innovation, {} is constantly exploring new techniques and materials to further enhance the quality of their products.Furthermore, {} is dedicated to sustainability and environmental responsibility. They strive to minimize waste and energy consumption in their manufacturing processes, and they work with eco-friendly materials whenever possible. This aligns with the growing demand for sustainable and eco-friendly products in the market, making {} an attractive partner for companies looking to reduce their environmental footprint.Despite the challenges posed by the global pandemic, {} has continued to thrive and grow. Their commitment to innovation and excellence has enabled them to adapt to the changing market conditions and meet the evolving needs of their clients. By leveraging their expertise in custom nylon parts, {} has been able to stay ahead of the competition and maintain their position as a leader in the industry.Looking ahead, {} is poised to expand their product offerings and reach new markets. With a strong focus on research and development, they are constantly exploring new possibilities and pushing the boundaries of what is possible with custom nylon parts. This dedication to innovation and excellence ensures that {} will continue to be a trusted partner for companies seeking high-quality nylon parts for their diverse applications.In conclusion, custom made nylon parts are playing a pivotal role in various industries, and {} is at the forefront of this trend. Through their dedication to quality, innovation, and customer satisfaction, {} has established itself as a leading manufacturer of custom nylon parts. With a focus on sustainability and a commitment to excellence, {} is well-positioned for continued success in the dynamic global marketplace.

Uncover the Different Types of Bridge Expansion Joints for Enhanced Infrastructure

Title: Types of Bridge Expansion Joints: Enhancing Infrastructure Resilience and DurabilityIntroduction:As our society continues to evolve, the need to improve our infrastructure becomes even more crucial. One vital component of infrastructure development is the construction and maintenance of bridges. These structures must be designed to endure heavy traffic, harsh weather conditions, and ensure the safety of the traveling public. In this article, we will explore various types of bridge expansion joints that play a vital role in increasing bridge durability and reducing maintenance costs.1. Modular Joints:Modular joints are a widely used type of expansion joint in modern bridge construction. These joints consist of a series of steel-edge beams connected by elastomeric seals. By allowing controlled movement during thermal expansion and contraction, modular joints enhance the bridge's ability to withstand temperature variations. They also provide a smooth ride for vehicles, eliminate noise and vibrations, and reduce stress on the bridge deck.2. Finger Joints:Finger joints, also known as comb joints, are another popular type of expansion joint commonly found in bridge construction. These joints offer significant movement capability and are designed to accommodate horizontal and vertical displacements. Finger joints consist of multiple steel plates with interlocking fingers, enabling the bridge to flex while maintaining structural integrity. While versatile and cost-effective, finger joints require regular maintenance to prevent debris accumulation and ensuring optimal functionality.3. Sliding Plate Joints:Sliding plate joints, as the name suggests, incorporate sliding elements to facilitate bridge displacement while maintaining stability. These joints consist of two plates that glide over one another to accommodate expansion and contraction of bridge components. The sliding plate joints effectively alleviate stress on the bridge structure, reducing internal forces and minimizing the risk of damage caused by temperature fluctuation. Regular lubrication is essential to ensure the smooth functioning of sliding plate joints.4. Elastomeric Joints:Elastomeric joints are flexible and provide exceptional movement accommodation, making them suitable for use in both highway and railway bridges. These joints are constructed using flexible rubber-like materials combined with steel reinforcements. Elastomeric joints isolate vibrations and transmit vertical and horizontal movements between bridge sections, reducing the potential for structural damage and enhancing passenger comfort. Routine inspections and maintenance are vital to monitor the condition of the elastomeric material and ensure optimal performance.5. Selective Movement Joints:Selective movement joints are specialized for accommodating the differential movement between adjacent bridge sections. This type of expansion joint allows for various types of movement, including lateral and rotational motions. Selective movement joints often feature a combination of materials, such as rubber and metal, to achieve the required functionality. Regular inspections and maintenance are necessary to preserve the desired range of motion and prevent potential joint failure.Conclusion:Bridge expansion joints are a vital part of infrastructure design, allowing for flexibility and durability in the face of dynamic environmental conditions. By understanding the various types of expansion joints available, engineers can ensure long-lasting bridge structures that offer enhanced resilience, reduced maintenance costs, and improved user experience. Investing in proper maintenance and periodic inspections will help maintain the effectiveness of these joints and contribute to the longevity and safety of our vital transportation infrastructure.

High-quality Heat Exchanger Tubes for Efficient Heat Transfer

Heat Exchanger Tubes: Ensuring Efficient Heat Transfer in Industrial ApplicationsAs industrial processes continue to become more sophisticated and complex, the demand for efficient heat transfer solutions has never been greater. Heat exchangers play a critical role in a wide range of industries, including power generation, chemical processing, and HVAC systems. At the heart of these heat exchangers are the tubes that facilitate the transfer of heat from one fluid to another. One company that has been at the forefront of providing high-quality heat exchanger tubes is {}.{} is a leading manufacturer and supplier of heat exchanger tubes, with a strong reputation for delivering innovative solutions that meet the evolving needs of the industry. The company offers a comprehensive range of heat exchanger tubes, including seamless and welded options, in a variety of materials such as stainless steel, copper, and titanium. With a focus on quality and reliability, {} has established itself as a trusted partner for businesses seeking reliable heat transfer solutions.The importance of heat exchanger tubes in industrial applications cannot be overstated. These tubes play a crucial role in facilitating the transfer of heat from one fluid to another, whether it's for heating, cooling, or condensing processes. In many industrial settings, the efficiency and effectiveness of heat exchangers can have a significant impact on overall productivity and operational costs. This is why the quality and performance of heat exchanger tubes are of utmost importance.{} understands the unique challenges that businesses face when it comes to heat transfer applications. That's why the company has invested heavily in research and development to engineer heat exchanger tubes that offer superior performance and durability. By leveraging the latest manufacturing technologies and adhering to strict quality control standards, {} is able to produce heat exchanger tubes that consistently deliver exceptional results in a wide range of operating conditions.One of the key advantages of {}'s heat exchanger tubes is their versatility. Whether it's for high-pressure, high-temperature, or corrosive environments, {} offers a diverse portfolio of heat exchanger tubes that can meet the most demanding requirements. This versatility extends to the company's ability to customize heat exchanger tubes to specific customer needs, ensuring that businesses can find the perfect solution for their unique applications.In addition to its commitment to product excellence, {} also places a strong emphasis on customer service. The company's team of technical experts and engineers are dedicated to providing comprehensive support to customers, from initial product selection to ongoing technical assistance. This level of support is invaluable to businesses that rely on heat exchanger tubes for critical processes, helping them optimize their operations and minimize downtime.Looking ahead, {} is poised to continue its leadership in the heat exchanger tube industry. With a focus on innovation and continuous improvement, the company is well-positioned to address the evolving needs of industrial heat transfer applications. Whether it's developing new materials, enhancing manufacturing processes, or expanding its product portfolio, {} remains committed to delivering cutting-edge solutions that empower businesses to achieve greater efficiency and performance.In conclusion, heat exchanger tubes are an essential component of industrial heat transfer systems, and {} has established itself as a trusted provider of high-quality tubes for a wide range of applications. Through its dedication to innovation, quality, and customer service, {} continues to be a reliable partner for businesses seeking to optimize their heat transfer processes. As industries continue to evolve, businesses can rely on {} to provide the heat exchanger tubes they need to stay ahead of the curve.

Top Filter Press Machine Suppliers for Max Filtration Efficiency

Filter Press Machine Manufacturers and Exporters in IndiaFilter press machines are an essential part of the industrial filtration process. They are used to separate solids and liquids in various industries such as pharmaceutics, chemical processing, food and beverage, and industrial wastewater treatment. Filter press machines are efficient, reliable, and cost-effective, making them a popular choice among manufacturers.One such company that has been providing top-quality filter presses to its customers is (brand name removed). (Brand name removed) is a leading manufacturer and exporter of filter press machines in India. With years of experience in the industry, they have become a trusted name for their clients.At (Brand name removed), they offer a wide range of filter presses that are designed to give maximum filtration efficiency, longer life, and least maintenance. These high-quality filter presses are known for their performance and durability. They are manufactured using the best quality raw materials and advanced technology, ensuring that they are of the highest standard.The filter presses offered by (Brand name removed) are available in various sizes and designs, depending on the specific requirements of their clients. They also offer customized filter press machines that are tailor-made to suit the specific needs of their clients.One of the key features of the filter press machines offered by (Brand name removed) is their ease of use. Their machines are user-friendly and easy to operate, making them ideal for first-time users. They also come with a detailed instruction manual that guides the operators through the entire process.Apart from the quality of their products, (Brand name removed) is also known for their excellent after-sales service. They have a team of highly skilled technicians who provide timely and efficient support to their clients. They are always ready to provide technical assistance and troubleshooting advice to their clients, ensuring that their filter press machines are always running at their optimal performance.(Customer testimonial): We have been using filter press machines from (Brand name removed) for several years now, and we are extremely satisfied with their product and service. Their machines are of great quality, and they have never let us down. Whenever we have faced any issues with the machines, their technicians have always been there to help us out. We would highly recommend (Brand name removed) to anyone who is looking for high-quality filter press machines.In conclusion, (Brand name removed) is a reliable and reputable filter press machine manufacturer and exporter in India. Their commitment to quality, performance, and customer service has earned them a distinguished reputation in the industry. Their products are used by some of the biggest names in the industry, and their machines have proven to be reliable and cost-effective. To know more about their products and services, visit their website today!

Discover Top Conveyor Systems and Rollers in Utah's Construction and Industry Directory

Roller Conveyor System: The Key to Streamlining Your Business OperationsEvery business owner wants to make their operations as efficient as possible. A streamlined process not only saves time and money but also ensures customer satisfaction. One essential element to achieving this goal is implementing a roller conveyor system.Conveyors have been around for centuries, enabling easy transportation of goods from one location to another. Over the years, conveyor systems have undergone significant innovation and advancement, making them an indispensable part of various industries, including manufacturing, packaging, and warehousing.A roller conveyor system, in particular, is an ideal choice for businesses that require moving heavy loads of varying shapes and sizes. Roller conveyors offer several benefits that make them an optimal choice for businesses looking to optimize their operations.Highly VersatileOne of the most significant advantages of roller conveyor systems is their versatility. They can be used to transport a variety of materials, including crates, boxes, pallets, and even delicate items. This versatility makes them an ideal option for businesses irrespective of their industry.Increased EfficiencyEfficiency is critical for successful business operations. With a roller conveyor system, you can transport goods efficiently from one location to another. The system is designed to minimize human intervention, ensuring a smooth and uninterrupted flow of materials. This not only saves time but reduces labor costs, enabling businesses to optimize their operations.Improved SafetySafety is a top priority in every business operation. Roller conveyor systems offer immense safety benefits as they minimize the risk of accidents and injuries. With a roller conveyor system, goods can be transported automatically, reducing the need for manual handling. By reducing the physical strain on employees, the risk of injury is significantly reduced, making the workplace safer.Cost-effective SolutionThe primary goal of every business is to make a profit while minimizing costs. The installation of roller conveyor systems is a one-time investment that provides significant long-term benefits. By reducing labor costs and increasing efficiency, businesses can generate more revenue, making the roller conveyor system a cost-effective investment.Enhanced Speed and AccuracySpeed and accuracy are essential in various business operations. A roller conveyor system is designed to transport goods at a consistent and fast pace, ensuring that products are delivered on time. This quick delivery ensures that customer satisfaction is maintained, enhancing brand reputation.In conclusion, a Roller Conveyor System is the key to optimizing business operations. With its versatility, increased efficiency, improved safety, cost-effectiveness, and enhanced speed and accuracy, this system is a must-have for businesses in any industry. At (brand name), we offer top-quality roller conveyor systems that are designed to meet the varying needs of our clients. Get in touch with us today to learn more about our products and how we can help streamline your business operations.

Efficient Slide Gates for Optimal Control of Bulk Materials in Pneumatic Conveying

in the article.Slide Gate Valve: The Versatile Choice for Dry Bulk Material ControlWhen it comes to managing dry bulk materials, ensuring efficient flow control is paramount. Not only does the material flow need to be regulated, but it must also be done so in a way that maintains process consistency and optimal flow rates. This is where slide gate valves come in.Slide gate valves are a versatile and effective solution for controlling gravity flow, dilute phase, or dense phase pneumatic conveying applications. Specifically designed for dry bulk handling, slide gate valves can regulate material flow from bins, hoppers, and silos to conveyors, chutes, and other receiving points.Slide gate valves offer several benefits for those seeking to regulate dry bulk materials in pneumatic or gravity conveying systems. Here are just a few of the many reasons why slide gate valves are a popular choice:Versatile and Effective DesignSlide gate valves are engineered to work with a variety of materials, including powders, granules, and pellets. They can also be customized to fit specific application needs, including sizes, shapes, and materials. The result is a highly effective solution that can be adapted to fit a wide range of requirements.Durable and DependableSlide gate valves are built to withstand harsh operating conditions, such as extreme temperatures, abrasive materials, and heavy loads. They are constructed from high-quality materials, including stainless steel and carbon steel, to ensure maximum durability.Low MaintenanceSlide gate valves are designed for easy installation and maintenance. They are typically self-cleaning and require minimal upkeep, making them an ideal choice for busy facilities looking to optimize their processes.Cost-EffectiveCompared to other flow control solutions, slide gate valves offer a low-cost alternative for regulating dry bulk materials. They are easy to install and require little maintenance over time, helping to reduce overall operational costs.Adaptable to Many ApplicationsSlide gate valves are suitable for use in a variety of industries, including food and beverage, pharmaceuticals, chemicals, plastics, and more. They can be customized to fit the specific needs of each application, making them an ideal choice for facilities seeking versatility and flexibility.In conclusion, slide gate valves are an excellent choice for regulating dry bulk materials in various pneumatic or gravity conveying applications. With their versatile design, durable construction, low maintenance requirements, and cost-effectiveness, they provide a highly effective solution for those seeking to optimize their processes for the long term. So if you are looking for an effective way to manage your dry bulk materials, consider investing in slide gate valves today!

High-quality Dismantling Joint With Butterfly Valve for Industrial Use

Leading the Way in Durable and Reliable Pipeline Solutions: Dismantling Joint With Butterfly ValveWith a focus on providing innovative and high-quality pipeline solutions, {Company Name} is proud to introduce their latest product, the Dismantling Joint With Butterfly Valve. This new addition to their extensive range of products is set to revolutionize the industry with its advanced design and superior performance.Designed to meet the growing demands of modern pipelines, the Dismantling Joint With Butterfly Valve offers a versatile and efficient solution for a wide range of applications. Whether it's in water supply systems, wastewater treatment plants, or industrial processes, this product has been engineered to deliver exceptional results under the most challenging conditions.One of the key features of the Dismantling Joint With Butterfly Valve is its innovative design, which allows for quick and easy installation and maintenance. This is made possible through the use of high-quality materials and precision engineering, ensuring a secure and reliable connection every time. Additionally, the butterfly valve provides excellent flow control, allowing for smooth and efficient operation of the pipeline.Furthermore, the dismantling joint feature of the product allows for easy access to the pipeline for inspection, maintenance, or repair, without the need for extensive and costly excavation. This not only reduces downtime and maintenance costs but also minimizes the impact on the surrounding environment, making it an environmentally friendly option for pipeline management.{Company Name} has a long-standing reputation for delivering durable and reliable pipeline solutions. With a commitment to quality, innovation, and customer satisfaction, they have become a trusted partner for businesses and organizations across various industries. Their team of experienced engineers and technicians continuously work to develop cutting-edge products that meet the evolving needs of the industry.The introduction of the Dismantling Joint With Butterfly Valve is a testament to {Company Name}'s dedication to innovation and excellence. By combining their extensive industry knowledge with the latest technological advances, they have created a product that sets new standards for pipeline connectivity and efficiency. This demonstrates their ongoing efforts to provide solutions that not only meet but exceed the expectations of their customers.In addition to the product's exceptional quality, {Company Name} also offers comprehensive support and technical expertise to ensure that their customers can maximize the benefits of the Dismantling Joint With Butterfly Valve. From installation guidance to ongoing maintenance, their team is committed to providing a seamless and hassle-free experience for their clients.As the demand for efficient and sustainable pipeline solutions continues to grow, {Company Name} remains at the forefront of the industry, leading the way with their innovative products and unwavering dedication to customer satisfaction. The introduction of the Dismantling Joint With Butterfly Valve is yet another example of their commitment to delivering cutting-edge solutions that address the evolving needs of the industry.In conclusion, the Dismantling Joint With Butterfly Valve from {Company Name} represents a significant advancement in pipeline technology. With its advanced design, reliable performance, and commitment to sustainability, this product is poised to set new standards for pipeline connectivity and efficiency. As {Company Name} continues to lead the way in delivering durable and reliable pipeline solutions, the introduction of this innovative product further solidifies their position as a trusted partner for businesses and organizations across various industries.

Top Quality Wear Components for Different Industries

Wear Components – A Leader in Providing High-Quality Parts for Industrial MachineryIn the fast-paced world of industrial manufacturing, equipment wear and tear is an inevitable issue that can cause significant downtimes and production delays. That's where Wear Components steps in, offering a wide range of high-quality aftermarket parts designed to keep industrial machinery running smoothly and efficiently. With a commitment to superior product quality and outstanding customer service, Wear Components has rapidly become a leader in the industry.Founded in [year], Wear Components has quickly built a reputation for excellence in providing wear parts for a wide variety of industrial machinery, including crushers, shredders, and conveyors. The company's mission is to help businesses minimize downtime and reduce maintenance costs by offering durable, long-lasting parts that meet or exceed OEM specifications.One of Wear Components' key differentiators is its dedication to product quality. The company leverages state-of-the-art manufacturing processes and advanced materials to ensure that every part it produces is of the highest caliber. In addition, all Wear Components parts undergo rigorous quality control testing to guarantee their performance and longevity in the field.“At Wear Components, we understand the critical role that our parts play in keeping industrial machinery operating at its best,” said [company spokesperson]. “That's why we go above and beyond to deliver parts that our customers can rely on. Our commitment to quality is unwavering, and we take immense pride in contributing to our clients' success.”In addition to providing top-notch parts, Wear Components also places a strong emphasis on customer service. The company's team of knowledgeable professionals is dedicated to helping customers find the right parts for their specific needs and offering expert advice to ensure optimal equipment performance.Unmatched customer service and a steadfast dedication to quality have solidified Wear Components' position as a trusted partner for countless businesses in the industrial sector. From small businesses to large corporations, Wear Components has earned a reputation for delivering exceptional value through its products and services.The company's comprehensive product line includes a wide range of wear parts, such as hammers, anvils, and impact plates for crushers, as well as shredder blades and conveyor components. Wear Components also offers custom manufacturing services, enabling customers to obtain bespoke parts tailored to their exact requirements.Moreover, maintaining a focus on sustainability, Wear Components is committed to continually improving its manufacturing processes to reduce its environmental impact. The company adheres to strict environmental standards and is dedicated to advancing sustainable practices across its operations.As Wear Components continues to expand its product offerings and enhance its customer support initiatives, the company's future outlook is promising. With a strong emphasis on innovation and an unwavering dedication to customer satisfaction, Wear Components is well-positioned to remain a leader in the industry for years to come.In conclusion, Wear Components has established itself as a premier provider of high-quality aftermarket parts for industrial machinery. With a relentless commitment to product excellence, unparalleled customer service, and a focus on sustainability, Wear Components continues to be an invaluable partner for businesses seeking to optimize the performance of their equipment. As industrial manufacturing continues to evolve, Wear Components is poised to remain at the forefront, delivering innovative solutions and exceptional value to its customers.