Benefits of Copper Expansion Joints for Industrial Applications

By:Admin

[City, State] - [Copper Expansion Joint] is pleased to announce the expansion of its operations in response to the growing demand for its high-quality products. The company has seen an increase in demand for its copper expansion joints, which are widely used in various industries to accommodate movement, vibration, and thermal expansion in piping systems.

[Copper Expansion Joint] has built a strong reputation for producing reliable and durable copper expansion joints that meet the highest industry standards. The company's expansion joints are designed to provide flexibility and noise reduction, making them a preferred choice for many industrial applications.

The decision to expand the company's operations comes as a result of the increasing demand for copper expansion joints in both domestic and international markets. With the expansion, [Copper Expansion Joint] aims to enhance its production capacity and better serve its growing customer base.

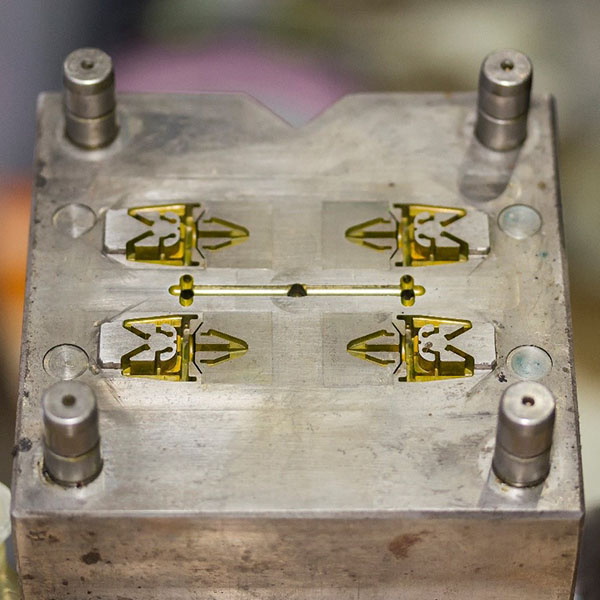

[Copper Expansion Joint]'s commitment to delivering top-quality products has been a driving force behind its success. The company utilizes advanced manufacturing techniques and state-of-the-art equipment to ensure that its copper expansion joints meet the stringent quality control standards.

In addition to its dedication to quality, [Copper Expansion Joint] is also known for its exceptional customer service. The company works closely with its clients to understand their specific requirements and provides customized solutions to meet their needs.

The expansion of [Copper Expansion Joint]'s operations will not only allow the company to meet the increasing demand for its products but will also create new job opportunities in the local community. The company plans to hire additional staff across various departments, including manufacturing, engineering, and customer service.

Furthermore, the expansion will enable [Copper Expansion Joint] to streamline its production processes and improve efficiency. By investing in new technologies and expanding its production facilities, the company aims to increase its output while maintaining the highest standards of quality.

As part of the expansion, [Copper Expansion Joint] is also exploring opportunities to reach new markets and expand its global presence. The company is committed to establishing strategic partnerships and distribution channels to make its products more accessible to customers worldwide.

[Copper Expansion Joint] remains focused on innovation and product development, aiming to continuously improve its product offerings and meet the evolving needs of its customers. The company's team of experienced engineers and technical experts is dedicated to researching and developing new solutions to address the challenges faced by industries that rely on copper expansion joints.

The expansion of [Copper Expansion Joint]'s operations reflects the company's confidence in the continued growth and success of its business. By increasing its production capacity, enhancing its product range, and expanding its market reach, [Copper Expansion Joint] is poised to solidify its position as a leading provider of copper expansion joints in the industry.

To learn more about [Copper Expansion Joint] and its products and services, please visit [company website] or contact the company directly at [company phone number] or [company email].

About [Copper Expansion Joint]:

[Copper Expansion Joint] is a leading manufacturer of high-quality copper expansion joints used in various industrial applications. The company is dedicated to providing reliable and durable solutions that meet the highest industry standards. With a focus on quality, innovation, and customer service, [Copper Expansion Joint] has built a strong reputation as a trusted supplier of copper expansion joints.

Company News & Blog

Different Types of Gate Valves: A Comprehensive Guide

Gate Valve Types and ApplicationGate valves are an essential component in many industrial processes, allowing for control of the flow of liquids and gases. There are various types of gate valves available, each suited to different applications. Understanding the different types of gate valves and their uses can help in selecting the right valve for specific needs.The most common types of gate valves include wedge gate valves, slab gate valves, and expanding gate valves. Each type has its own unique features and advantages, making them suitable for various industrial applications.Wedge gate valves are one of the most widely used types of gate valves. They feature a gate with two inclined seats, allowing for a tight seal and reduced friction during operation. Wedge gate valves are commonly used in low-pressure applications, such as water and wastewater systems, as well as in the oil and gas industry.Slab gate valves are another popular type of gate valve, featuring a single gate design that provides a tight seal and excellent resistance to high-pressure and high-temperature conditions. Slab gate valves are commonly used in the oil and gas industry, where they are required to withstand harsh operating conditions.Expanding gate valves are designed with a gate that expands against the seats to create a tight seal. These valves are commonly used in high-temperature and high-pressure applications, such as steam systems and power plants, where a reliable and resilient valve is essential.In addition to the different types of gate valves, it is essential to consider the materials used in their construction. Gate valves can be made from various materials, including carbon steel, stainless steel, and exotic alloys, each suited to different operating conditions and environments.Company Introduction {}With a rich history of over 50 years in the manufacturing and supply of industrial valves, {Company Name} has earned a reputation for excellence in the industry. Specializing in the production of high-quality gate valves, the company has a wide range of products that cater to various industrial sectors, including oil and gas, petrochemical, power generation, and water and wastewater treatment.{Company Name} prides itself on its commitment to quality and innovation, ensuring that its products meet the highest standards of performance and reliability. With state-of-the-art manufacturing facilities and a team of experienced engineers and technicians, the company continues to be at the forefront of valve technology, developing advanced solutions to meet the evolving needs of the industry.In addition to its extensive product range, {Company Name} offers custom valve solutions, working closely with clients to design and manufacture valves tailored to their specific requirements. The company's dedication to customer satisfaction and technical expertise has established it as a trusted partner for industrial valve solutions.As a global leader in the valve industry, {Company Name} is committed to sustainability and environmental responsibility, implementing efficient and eco-friendly manufacturing processes and adhering to strict quality and safety standards.In conclusion, gate valves are essential components in many industrial processes, and selecting the right type of valve for specific applications is crucial to ensuring optimal performance and reliability. With a diverse range of gate valves and a commitment to quality and innovation, {Company Name} continues to be a trusted partner for industrial valve solutions, providing high-quality products that meet the most demanding requirements.

Quality Wear Parts for Industrial Machinery: A Complete Guide

Wear Parts, a leading global provider of high-quality wear parts for various industries, has recently announced the launch of their new line of innovative and durable wear parts. With over [number] years of experience in the industry, Wear Parts has built a reputation for delivering superior products and exceptional customer service.The company specializes in manufacturing wear parts for a wide range of industries including mining, construction, agriculture, and recycling. Their extensive product line includes crusher wear parts, shredder wear parts, and grinding mill liners, among others. This comprehensive range of products allows Wear Parts to cater to the diverse needs of their clients and provide customized solutions that meet specific requirements.One of the key factors that sets Wear Parts apart from their competitors is their unwavering commitment to quality. The company utilizes advanced manufacturing processes and high-quality materials to ensure that their wear parts are of the highest standards. Additionally, their team of skilled engineers and technicians continuously strive to develop and improve their products to ensure optimal performance and durability.In addition to their dedication to quality, Wear Parts places a strong emphasis on customer satisfaction. They work closely with their clients to understand their unique needs and provide tailored solutions that deliver maximum value. Whether it's providing expert advice on wear part selection or offering timely technical support, Wear Parts goes above and beyond to ensure that their customers are well taken care of.Furthermore, Wear Parts has a global distribution network that enables them to serve customers in various parts of the world. Their efficient logistics and timely delivery ensure that clients receive their wear parts on time, minimizing downtime and maximizing productivity.As part of their commitment to innovation, Wear Parts is continuously investing in research and development to create cutting-edge wear parts that offer superior performance and longevity. They understand the importance of staying ahead of industry trends and technological advancements, and strive to bring the latest innovations to their clients."We are thrilled to launch our new line of wear parts, which we believe will set new standards in the industry," said [Name], CEO of Wear Parts. "Our team has worked tirelessly to develop products that not only meet but exceed the expectations of our customers. We are confident that these wear parts will deliver exceptional value and performance to our clients across the globe."In line with their mission to provide top-quality wear parts, Wear Parts is committed to sustainability and environmental responsibility. They prioritize eco-friendly manufacturing processes and are constantly seeking ways to reduce their environmental impact. By investing in sustainable practices, they aim to contribute to a cleaner and greener future for the industry.As Wear Parts continues to expand their product offerings and reach new markets, they remain committed to upholding their core values of quality, customer satisfaction, innovation, and sustainability. Their dedication to excellence has earned them the trust and loyalty of numerous clients worldwide, and they are poised to continue their upward trajectory in the wear parts industry.About Wear Parts:Wear Parts is a leading global provider of high-quality wear parts for the mining, construction, agriculture, and recycling industries. With a focus on quality, innovation, and customer satisfaction, Wear Parts has established itself as a trusted partner for clients worldwide. Their extensive product line and commitment to excellence have made them a preferred choice for wear parts solutions. For more information, visit [company website].

Essential Guide to Conveyor Belt Splicing

Conveyor Belt Splicing is a crucial process in the maintenance and repair of conveyor systems. It involves the joining of two conveyor belts to ensure a continuous and smooth material flow along the conveyor line. This process is essential in industries such as mining, manufacturing, and logistics, where conveyor systems play a vital role in the efficiency of operations.As a leader in the conveyor maintenance and repair industry, {} has been providing high-quality conveyor belt splicing services to its clients for over two decades. With a team of experienced technicians and state-of-the-art equipment, {} has established itself as a reliable partner for companies seeking to optimize their conveyor systems.The process of conveyor belt splicing involves several important steps. Firstly, the damaged or worn-out section of the conveyor belt is identified and removed. Then, the two ends of the new belt are prepared for splicing by trimming them to ensure a smooth and even joint. The next step involves the use of specialized equipment, such as vulcanizing presses and splicing tools, to join the two belt ends together using adhesives or heat. This results in a seamless joint that maintains the strength and flexibility of the conveyor belt.{} understands the importance of using the right techniques and materials for conveyor belt splicing. They offer a range of splicing options, including mechanical splicing, hot vulcanization, and cold bonding, to suit the specific needs of their clients. The company's team of technicians is trained to assess the condition of conveyor belts and recommend the most appropriate splicing method to ensure the longevity and reliability of the conveyor system.In addition to offering conveyor belt splicing services, {} also provides comprehensive conveyor maintenance and repair solutions. This includes regular inspections, cleaning, and lubrication of conveyor components to prevent downtime and ensure smooth operation. The company also specializes in the replacement of conveyor components such as pulleys, idlers, and bearings, further enhancing the performance of conveyor systems.{} takes pride in its commitment to providing cost-effective and efficient solutions for conveyor maintenance and repair. Their team works closely with clients to understand their specific requirements and develop customized splicing and maintenance plans that align with their operational needs. Through their proactive and preventive approach, {} helps clients minimize the risk of unexpected conveyor failures and costly downtime.The reliability and expertise of {} in conveyor belt splicing have earned them a strong reputation in the industry. Their clients trust them to deliver high-quality splicing services that prolong the life of their conveyor systems and ensure uninterrupted material handling operations. With a focus on innovation and continuous improvement, {} remains at the forefront of the conveyor maintenance and repair industry, consistently meeting the evolving needs of their clients.In conclusion, conveyor belt splicing is a critical process in the maintenance and repair of conveyor systems, and {} has established itself as a leading provider of splicing services. With their expert team, comprehensive solutions, and commitment to customer satisfaction, {} continues to set the standard for excellence in the conveyor maintenance and repair industry.

Guide to Hydraulic Flow Control Valves: What You Need to Know

In the world of industrial engineering, the importance of hydraulic flow control valves cannot be overstated. These critical components are integral to the operation of a wide range of machinery, from heavy industrial equipment to precision manufacturing tools. In order to meet the growing demand for high-quality hydraulic flow control valves, {company name} has emerged as a leading provider of cutting-edge solutions for industry professionals.Founded in {year}, {company name} has quickly gained a reputation for excellence in the field of hydraulic engineering. The company's team of experts boasts over {number} years of combined experience in the design, development, and production of hydraulic flow control valves. With a dedication to innovation and a commitment to meeting the needs of their clients, {company name} has become a trusted name in the industry.One of the key products offered by {company name} is their {model name} hydraulic flow control valve. This state-of-the-art valve incorporates the latest advancements in hydraulic engineering technology, offering users precise control over the flow of hydraulic fluid in their machinery. This level of control is essential for ensuring the optimal performance and safety of industrial equipment, making the {model name} valve a valuable asset for professionals in a wide range of industries.The {model name} valve is designed to meet the highest standards of quality and reliability. Constructed from durable materials and subjected to rigorous testing, this valve is built to withstand the demands of even the most challenging industrial environments. This level of durability provides users with the peace of mind that comes with knowing their equipment is equipped with components that are designed to deliver reliable performance under any conditions.In addition to their commitment to quality, {company name} also prides itself on its ability to provide custom solutions to meet the unique needs of their clients. The company's team of engineers works closely with each client to understand their specific requirements and develop tailored solutions that address their individual challenges. This level of personalized service sets {company name} apart from its competitors and has helped to establish the company as a preferred partner for businesses seeking high-quality hydraulic flow control valves.Beyond its products and services, {company name} is also dedicated to fostering innovation and excellence within the industry. The company invests heavily in research and development, constantly striving to push the boundaries of what is possible in the field of hydraulic engineering. By staying at the forefront of technological advancements, {company name} is able to offer its clients the most advanced and effective solutions available, ensuring that they are equipped to succeed in an ever-evolving industrial landscape.Looking to the future, {company name} is poised to continue its trajectory of growth and success. With a steadfast commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the needs of an expanding customer base and to lead the way in the development of next-generation hydraulic flow control valves. By remaining true to its core values and continuing to prioritize the success of its clients, {company name} is sure to remain a prominent figure in the industry for years to come.

Rubber Expansion Joint: A Reliable Solution for Concrete Structures

Title: Innovative Rubber Expansion Joint for Concrete Enhances Durability and Safety in Construction ProjectsIntroduction:In the ever-evolving field of construction, ensuring the longevity and safety of structures is of paramount importance. To address this need, an industry-leading company, specializing in construction materials and solutions, has introduced an innovative rubber expansion joint for concrete. Leveraging their extensive expertise in the field, the company aims to revolutionize construction practices by providing a durable and safety-enhancing solution. This article will delve into the key features and benefits of this groundbreaking product, shedding light on how it can positively impact the construction industry.Key Features:The newly introduced rubber expansion joint for concrete boasts several key features that set it apart from traditional alternatives. The joint is manufactured using high-quality rubber, sourced from reputable suppliers, guaranteeing its durability and long-lasting performance. With a unique design, the expansion joint effectively accommodates the movement and deformation of concrete structures, providing superior flexibility and preventing cracks or damage caused by thermal expansion, seismic activity, or other environmental factors.Moreover, this rubber expansion joint offers excellent resistance to chemicals, water penetration, and ultraviolet (UV) radiation, ensuring that the integrity of structures remains intact even in harsh environments. These properties make it an ideal choice for various applications, including transportation infrastructure, commercial buildings, industrial facilities, and more.Benefits for Construction Industry:1. Enhanced Durability: The rubber expansion joint offers exceptional resistance to wear and tear, significantly reducing maintenance costs and efforts. Its ability to accommodate movements and deformations in concrete structures prevents cracks and damage, thereby extending the lifespan of the construction project.2. Safety Enhancement: By effectively absorbing vibrations and reducing the transfer of impact loads, this expansion joint minimizes the risk of structural failures and compromised safety in buildings and infrastructure. As a result, it enhances the overall safety of construction projects, ensuring the protection of occupants and surrounding areas.3. Versatility and Adaptability: The innovative design of this rubber expansion joint allows for easy installation and retrofitting, making it suitable for both new construction projects and renovations. Its adaptability to various applications, such as highways, bridges, parking lots, and commercial buildings, offers flexibility for engineers, architects, and contractors.4. Cost-Effectiveness: With its long-lasting performance and reduced maintenance requirements, the rubber expansion joint proves to be a cost-effective investment. Construction companies can avoid expensive repairs and replacements, saving both time and money in the long run.Company Profile and Expertise:As a leading provider of construction materials and solutions, {}, the company behind this revolutionary rubber expansion joint, boasts an extensive track record of successful projects across diverse industries. With a team of experienced professionals, they prioritize customer satisfaction, delivering bespoke solutions tailored to meet specific construction requirements.The company's commitment to innovation and quality ensures that their products not only meet industry standards but also surpass customer expectations. They collaborate closely with engineers, architects, and contractors to continuously improve their offerings, addressing emerging needs in construction practices.Conclusion:The introduction of the rubber expansion joint for concrete marks a significant milestone in the construction industry. With its exceptional durability, safety enhancement, versatility, and cost-effectiveness, this innovative solution promises to reshape construction practices, ensuring the longevity and safety of structures. As the market demands sustainable and high-performance materials, companies like {} continue to push boundaries with their dedication to innovation, ultimately advancing the construction field for a better and safer future.

Durable and Flexible Rubber Air Line Hose for Improved Air Flow and Performance

[Company Introduction] is a leading manufacturer of industrial rubber products, specializing in the production of high-quality rubber hoses for various applications. With decades of experience and a commitment to excellence, the company has established itself as a trusted supplier of industrial rubber products to customers worldwide. Its dedication to innovation and quality has set it apart in the industry, and its products are known for their durability, reliability, and performance.[Company Name]'s extensive product range includes rubber air line hoses that are designed for use in a wide range of industrial and commercial settings. These hoses are engineered to withstand the rigors of demanding applications and provide reliable performance in even the harshest environments. The company's rubber air line hoses are constructed from premium quality materials to deliver superior flexibility, durability, and resistance to abrasion, making them an ideal choice for a variety of air transfer applications.[News Content][Company Name] recently announced the release of its latest innovation in rubber air line hoses, designed to meet the evolving needs of the industrial sector. The new product is the result of extensive research and development, aimed at delivering a hose that sets new standards for performance, durability, and reliability. This cutting-edge hose is engineered to excel in demanding applications, delivering the flexibility and strength needed to handle a variety of air transfer tasks.The new rubber air line hose features a reinforced construction that enhances its durability and resistance to wear and tear, ensuring a longer service life and reducing the need for frequent replacements. Its high-quality rubber material is selected for its excellent flexibility and ability to handle high-pressure air transfer, making it suitable for use in a wide range of industrial environments. The hose also incorporates advanced technology to resist kinking, making it easier to handle and reducing the risk of damage during use.In addition to its exceptional performance characteristics, the new rubber air line hose from [Company Name] is designed with safety in mind. It meets stringent industry standards for pressure ratings and is engineered to withstand the challenges of heavy-duty applications, providing peace of mind to users who depend on reliable air transfer solutions. This focus on safety and quality reflects [Company Name]'s commitment to delivering products that not only meet but exceed customer expectations, setting new benchmarks for excellence in the industry.The new rubber air line hose is available in a range of sizes and configurations to suit different application requirements, offering customers the flexibility to choose the best solution for their specific needs. Whether it's for use in factories, workshops, construction sites, or other industrial settings, this versatile hose is designed to deliver consistent performance and exceptional durability, contributing to increased productivity and efficiency in the workplace.With the release of its latest innovation in rubber air line hoses, [Company Name] continues to demonstrate its leadership and expertise in the industrial rubber products sector. By combining advanced engineering, quality materials, and a steadfast commitment to customer satisfaction, the company remains at the forefront of delivering innovative solutions that empower businesses to thrive in today's competitive marketplace.As a trusted supplier of industrial rubber products, [Company Name] is dedicated to supporting the success of its customers by providing superior products, personalized service, and reliable technical expertise. With the introduction of its new rubber air line hose, the company reinforces its position as a go-to partner for businesses seeking high-performance rubber products that meet the highest standards of quality and reliability.In conclusion, the launch of the new rubber air line hose from [Company Name] represents a significant milestone in the company's ongoing commitment to innovation and excellence. As industries continue to evolve and demand increasingly robust solutions, [Company Name] remains steadfast in its mission to deliver products that raise the bar for performance and durability, setting new industry benchmarks and empowering businesses to achieve their goals with confidence.

High quality spare parts for jaw crushers available now

A leading manufacturer of mining machinery, with years of experience in the industry, has recently announced the release of their newly developed jaw crusher spare parts. These high-quality spare parts are designed to improve the efficiency and performance of jaw crushers, ensuring that customers can achieve the maximum productivity from their equipment.The company's dedication to innovation and excellence has led to the development of these jaw crusher spare parts, which are designed to withstand the rigors of heavy-duty crushing applications. With a focus on improving the overall reliability and longevity of jaw crushers, these spare parts are precision-engineered to meet the specific requirements of the crushing process.The jaw crusher spare parts are manufactured using high-quality materials and advanced technology, ensuring that they can withstand the toughest working conditions. The company's extensive research and development efforts have resulted in the creation of spare parts that offer superior performance and durability, reducing the risk of unexpected downtime and maintenance costs for customers.In addition to their exceptional quality, the jaw crusher spare parts are also designed to be easy to install and maintain, allowing customers to minimize the time and effort required to keep their equipment in optimal working condition. This user-friendly approach reflects the company's commitment to providing practical solutions that enhance the overall operational efficiency of jaw crushers.Furthermore, the company's extensive inventory of jaw crusher spare parts ensures that customers can easily find the specific components they need, reducing the lead time for replacements and repairs. With a comprehensive range of spare parts available, customers can rely on the company to provide prompt and reliable support for their maintenance and repair needs.The release of these jaw crusher spare parts further solidifies the company's position as a trusted provider of mining equipment and solutions. With a proven track record of delivering high-quality products and exceptional customer service, the company has earned a strong reputation in the industry for its commitment to excellence.As a leading manufacturer of mining machinery, the company is dedicated to meeting the evolving needs of its customers, providing innovative solutions that improve the performance and efficiency of their operations. The development of these jaw crusher spare parts exemplifies the company's ongoing efforts to deliver valuable, cost-effective solutions that enable customers to optimize their crushing processes.With a team of experienced engineers and technical experts, the company remains at the forefront of technological advancements in the mining industry. This expertise allows them to continually innovate and improve their product offerings, ensuring that customers have access to the latest advancements in crushing technology.In conclusion, the release of the jaw crusher spare parts underscores the company's commitment to providing practical, high-quality solutions for the mining industry. With their focus on performance, durability, and user-friendliness, these spare parts are set to enhance the productivity and reliability of jaw crushers for customers. As the company continues to push the boundaries of innovation, customers can expect to benefit from even more groundbreaking developments in the future.

High-quality Oil Hose for Industrial and Automotive Use

Rubber Oil Hose Provides Superior Quality and Durability for Various IndustriesIn today's industrial and manufacturing sector, the demand for high-quality rubber oil hoses has significantly increased. These hoses play a crucial role in transferring oil, petroleum, and other chemical substances in a safe and efficient manner. One company that has been at the forefront of providing superior quality rubber oil hoses is [Need remove brand name].[Need remove brand name] is a renowned manufacturer and supplier of rubber oil hoses that are designed to meet the diverse needs of different industries. With a strong emphasis on quality, durability, and performance, the company has established a solid reputation for providing reliable solutions that exceed industry standards.The rubber oil hoses offered by [Need remove brand name] are engineered to withstand the harshest working conditions and are highly resistant to abrasion, corrosion, and extreme temperatures. This makes them an ideal choice for use in a wide range of applications, including oil and gas exploration, automotive, marine, and industrial manufacturing.One of the key factors that set [Need remove brand name] apart from its competitors is its commitment to using high-quality materials and advanced manufacturing processes. The company utilizes premium grade rubber compounds that are formulated to deliver exceptional flexibility, strength, and chemical resistance. Additionally, the hoses are reinforced with multiple layers of high-strength synthetic fibers or steel wire, ensuring maximum durability and longevity."We take great pride in the superior quality of our rubber oil hoses, and we are dedicated to continuously improving and innovating our products to meet the evolving needs of our customers," said a spokesperson from [Need remove brand name]. "Our hoses undergo rigorous testing and quality control measures to ensure that they meet or exceed industry standards, providing our clients with peace of mind and confidence in the performance of our products."The diverse range of rubber oil hoses offered by [Need remove brand name] caters to a wide spectrum of applications, including suction and discharge hoses, fuel delivery hoses, hydraulic hoses, and composite hoses. Whether it's for transferring crude oil, diesel, gasoline, or chemicals, the company provides solutions that are tailored to the specific requirements of each customer and application.In addition to delivering high-quality products, [Need remove brand name] places a strong emphasis on customer satisfaction and support. The company's team of technical experts and engineers work closely with clients to understand their needs and provide customized solutions that best fit their applications. Furthermore, [Need remove brand name] offers comprehensive after-sales service, technical assistance, and maintenance support to ensure the optimal performance and longevity of its rubber oil hoses.As [Need remove brand name] continues to expand its presence in the global market, the company remains committed to upholding its core values of quality, innovation, and customer-centric approach. With a strong focus on research and development, [Need remove brand name] is dedicated to staying ahead of industry trends and technological advancements, while consistently delivering reliable and high-performance rubber oil hoses.In conclusion, the demand for high-quality rubber oil hoses is expected to continue growing as industries strive for efficient and reliable solutions for transferring oil and chemical substances. With its unwavering commitment to superior quality, durability, and customer satisfaction, [Need remove brand name] is well-positioned to meet the evolving needs of the industrial and manufacturing sector, providing innovative and reliable rubber oil hose solutions.

Metal Conveyor Belts: A Wide Range of Fit for Purpose Solutions for Every Application

Metal Conveyor Belts: Durable and VersatileMetal conveyor belts have become increasingly popular in modern industrial settings because of their durability and versatility. These belts can withstand extreme temperatures, harsh chemicals, heavy loads, and abrasive environments like no other. As a result, metal conveyor belts are a go-to solution in various industries such as food processing, automotive manufacturing, and packaging.Chain Conveyor Belt: A Type of Metal Conveyor BeltOne type of metal conveyor belt is the chain conveyor belt. It consists of interlocking metal links that are hinged or welded together to form an endless belt. The chain conveyor belt is specifically designed for heavy-duty applications, like carrying large loads over long distances. It offers a high level of reliability, performance, and low maintenance.Applications of Chain Conveyor BeltsChain conveyor belts are highly versatile and can be used in a variety of industries, including:1. Automotive industry: Chain conveyor belts are used for conveying car parts such as engines, tires, and chassis through the assembly line.2. Food processing industry: Chain conveyor belts are ideal for transporting food products such as meat, vegetables, and fruits. They are easy to clean and sanitize, making them suitable for food contact.3. Mining industry: Chain conveyor belts are commonly used in mining applications where heavy loads of ores and minerals need to be transported over long distances.Advantages of Chain Conveyor Belts1. Durability: Chain conveyor belts are made of high-quality materials, including stainless steel, carbon steel, and plastic. They are designed to last long and stand up against heavy use and harsh conditions.2. Versatility: Chain conveyor belts can handle various shapes and sizes of products, making them suitable for a wide range of industrial applications.3. Easy maintenance: Chain conveyor belts are easy to maintain and repair. They are designed with removable links, making it simple to replace damaged parts without having to replace the entire belt.4. Customization: Chain conveyor belts can be customized to fit specific industrial applications. This includes adjusting the width, length, material, and construction of the belt to meet the needs of different industries.Final ThoughtsChain conveyor belts are a type of metal conveyor belt that offers numerous advantages and applications in various industries. They are a reliable, durable, and versatile solution for heavy-duty and long-distance transportation jobs. If you're looking for a belt that can handle demanding conditions with ease, a chain conveyor belt may be the right choice for you.

Expert Tips for Conveyor Belt Splicing Techniques: Best Methods Revealed

Tips and Procedures for Splicing Conveyor Belts: Why Hot Vulcanization is RecommendedConveyor belts play a critical role in the transportation of varying products in different manufacturing and industrial settings. With the constant use of conveyor belts, it's inevitable that they will eventually wear and tear, break, and require repair. In such moments, conveyor belt splicing is essential.Several methods can be used to splice conveyor belts, including mechanical splicing and hot vulcanization. However, when it comes to choosing the best option, experts recommend hot vulcanization. This method involves the use of heat and pressure to bond the repair material to the damaged area, making it a durable, strong, and long-lasting solution.Why Choose Hot Vulcanization?Although hot vulcanization is more expensive and takes longer than mechanical splicing, it offers numerous benefits. Some of these benefits include:1. High Quality and Long-Lasting RepairsHot vulcanization enables you to achieve high-quality, long-lasting conveyor belt splicing solutions. The vulcanized splice is strong, durable, and often outlasts the original belt. The method ensures that you don't have to worry about conveyor downtime due to belt failure.2. Improved SafetyImproved safety is a significant benefit of vulcanized conveyor splicing. The process helps ensure that the conveyor belt is strong and direct to avoid accidents in the workplace. A damaged conveyor belt can result in injury or accidents that can cause significant damage to personnel, facilities, machinery, and products.3. Increased Conveyor EfficiencyVulcanized conveyor belt splicing helps optimize conveyor efficiency by minimizing downtime and reducing maintenance costs. This implies that you can focus more on production and less on conveyor maintenance, repair, and replacement.Procedures for Hot Vulcanization of Conveyor BeltsVulcanizing a conveyor belt involves several steps, including preparation, curing, and finishing. Here is a step-by-step guide to hot vulcanizing conveyor belts:1. Preparationa) Clean the damaged area by removing any dirt or debris.b) Mark the damaged section of the belt using a chalk or marker.c) Cut along the marked section using a repair strip cutter.d) Trim the end of the cut to make the repair strip neat.e) Buff both the belt and repair strip with a grinder to create a smooth surface.2. Curinga) Lay the belt ends together on a curing table and ensure that the splices are square.b) Apply hot vulcanizing material to both the belt ends.c) Use a putty knife to spread the material evenly.d) Position the repair strip and ensure that it covers the entire damaged area.e) Cover the repair strip with a release cloth.f) Use a vulcanizer to heat the splice to cure the hot vulcanizing material.3. Finishinga) Remove the release cloth.b) Cut any excess material from around the splice.c) By using a pry bar, carefully remove the splicing frame.d) Finally, inspect the conveyor belt to ensure the splice is cured correctly.In conclusion, conveyor belt splicing is a crucial process that should be taken seriously to ensure that the conveyor system operates smoothly and efficiently. Although there are several different belt splicing methods, hot vulcanization is the most reliable and durable solution. Following the proper hot vulcanization procedures will guarantee a high-quality repair that will last for an extended period.